Halogen-free and highly-heatproof resin composition for copper-clad board

A resin composition, high heat resistance technology, applied in the field of copper clad laminates, can solve problems such as circuit short circuit, affecting circuit, open circuit, etc., and achieve the effect of reducing expansion coefficient, excellent dielectric properties, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention discloses a halogen-free high heat-resistant resin composition for copper-clad laminates. Based on 100 parts by weight of organic solids (PHR), the composition contains the following main components:

[0051] (a) Main chain benzoxazine resin 5-60PHR containing polystyrene;

[0052] (b) High heat-resistant epoxy resin 20-50PHR;

[0053] (c) Other curing agent 5-30PHR;

[0054] (d) Toughening resin 0.1-10PHR;

[0055] (d) Phosphorous flame retardant 10-30PHR;

[0056] (e) Inorganic filler 40~150PHR;

[0057] (d) curing accelerator 0.01 ~ 1PHR;

[0058] (f) silane coupling agent 0.01~1PHR;

[0059] (g) An appropriate amount of solvent.

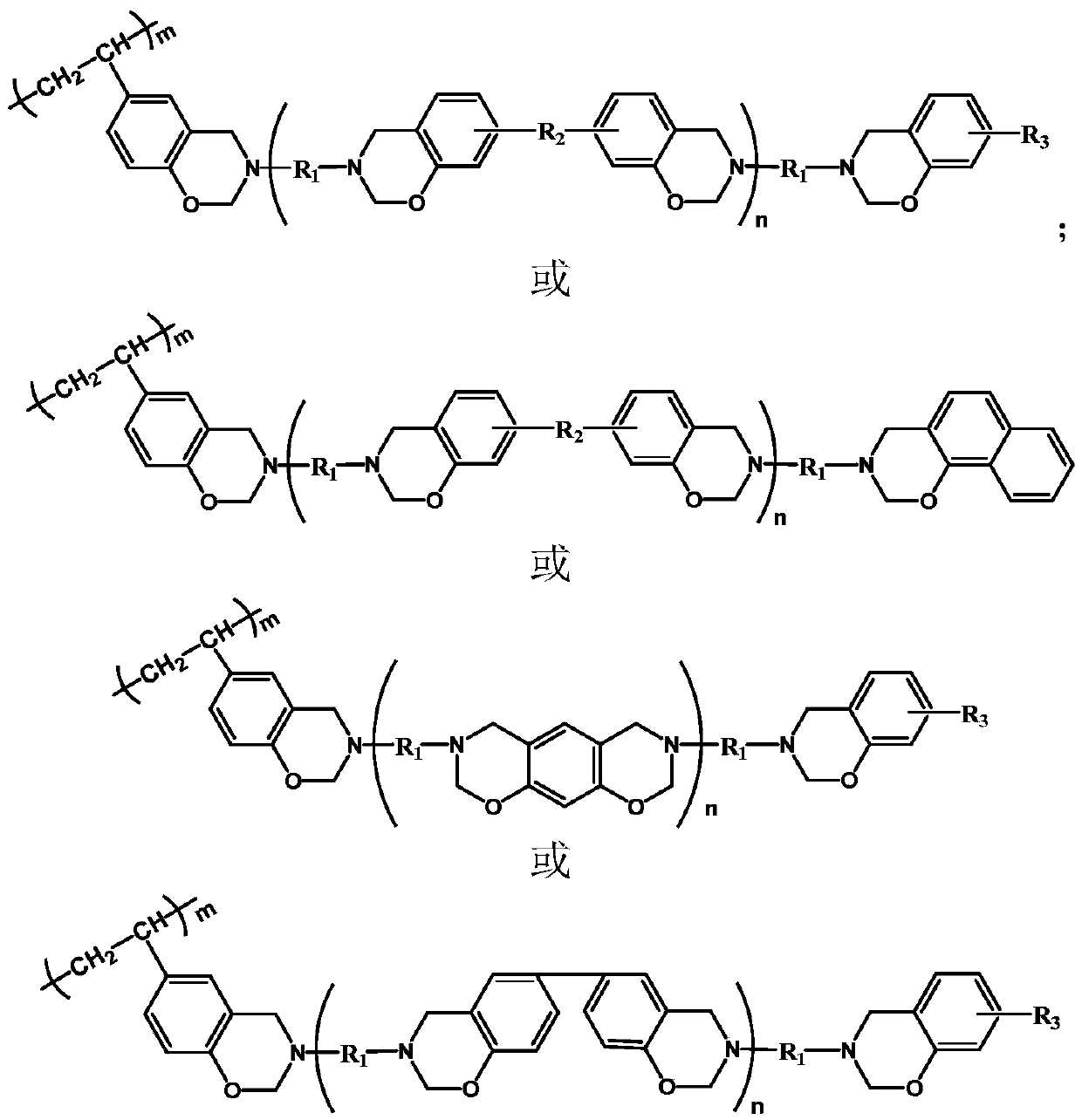

[0060] The main chain benzoxazine resin containing polystyrene has the following general structural formula:

[0061]

[0062] In the formula, m is 1-200, n is 1-5,

[0063] R 1 for R 2 for R 3 for

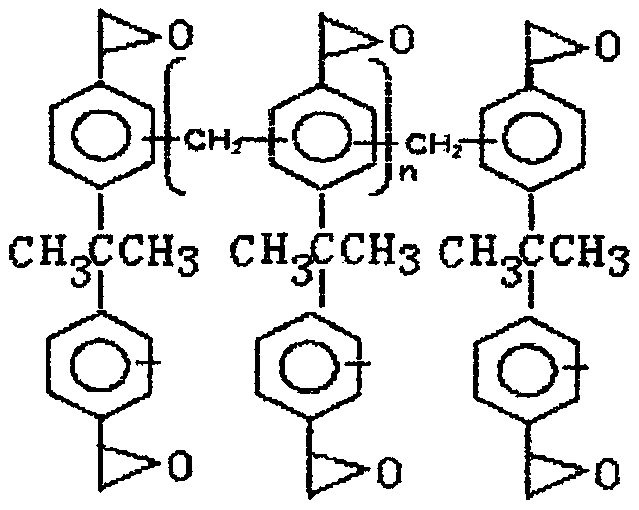

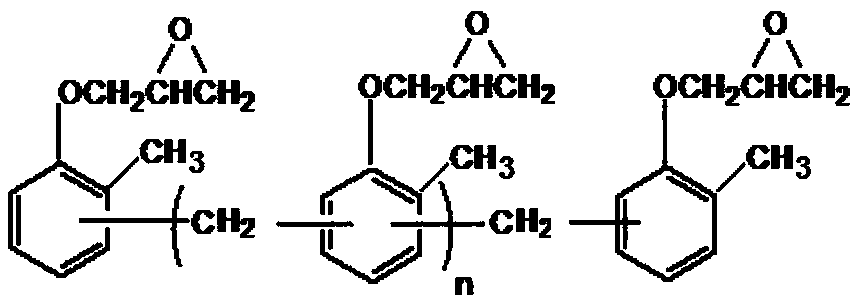

[0064] The high heat-resistant epoxy resin is bisphenol A type novolak epoxy resin, o-cresol novol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com