Corrosion inhibition bactericide for oil fields, and preparation method thereof

A bactericide and corrosion-inhibiting technology, applied in the field of oil field corrosion-inhibiting bactericides and their preparation, can solve problems such as poor bactericidal effect, and achieve the effects of slowing down corrosion and inhibiting the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

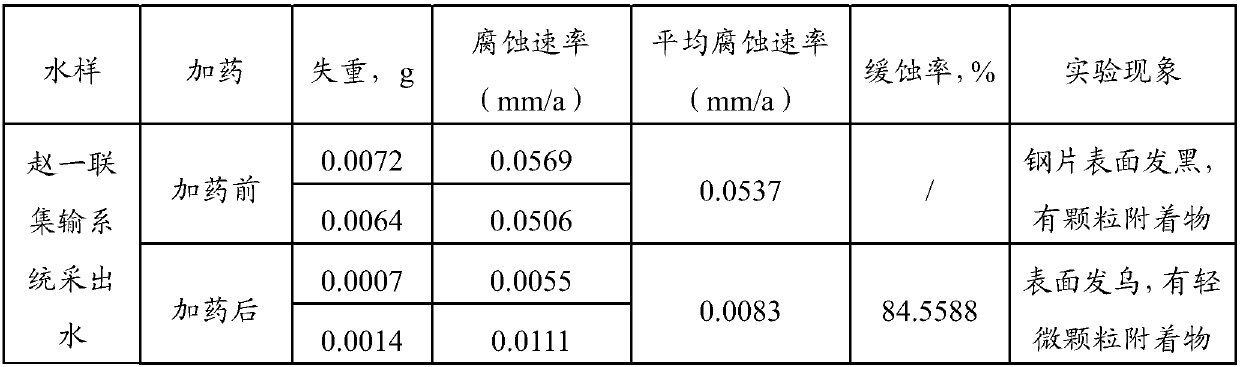

Examples

Embodiment 1

[0091] Embodiment 1 of the present invention provides a corrosion inhibitor and fungicide for oil fields.

[0092] Polymerized organic guanidines are prepared by the following steps:

[0093] In a four-necked flask equipped with a mechanical stirrer, a reflux condenser, a thermometer and an ammonia absorption device, add 11.88 parts by weight of hexamethylenediamine diacetyl, 5.28 parts by weight of guanidine hydrochloride and 10.89 parts by weight of ethylene glycol in proportion , heated to 100°C, reacted for 4 hours, then raised the temperature to 180°C, and continued to react for 2 hours to obtain polymerized organic guanidine.

[0094] The preparation method of anti-corrosion fungicide for oil field:

[0095] First, add 10 parts by weight of oleic acid-based hydroxyethylimidazoline and 20 parts by weight of dodecyldimethylbenzyl ammonium chloride into the reaction kettle, stir and heat to 50°C,

[0096] Then add the 3 parts by weight of hydroxyethylidene diphosphonic ac...

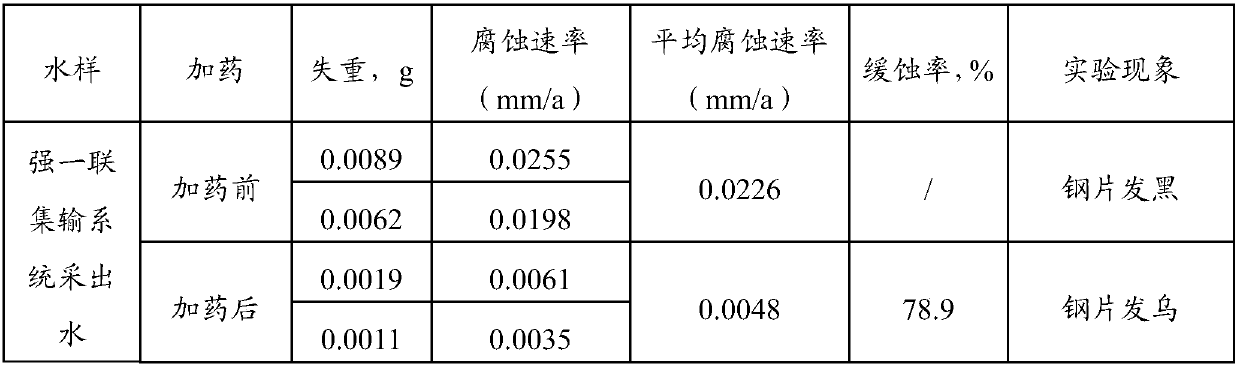

Embodiment 2

[0111] Embodiment 2 of the present invention provides a corrosion inhibitor and fungicide for oil fields.

[0112] Polymerized organic guanidines are prepared by the following steps:

[0113] In the four-necked flask equipped with mechanical stirring, reflux condenser, thermometer and ammonia absorption device, add 12.48 parts by weight of diacetylhexamethylenediamine, guanidine hydrochloride of 9.36 parts by weight and ethylene glycol of 10.58 parts by weight respectively , heated to 100°C, reacted for 4 hours, then raised the temperature to 180°C, and continued to react for 2 hours to obtain polymerized organic guanidine.

[0114] The preparation method of anti-corrosion fungicide for oil field:

[0115] First, add the 8 parts by weight of oleic acid-based hydroxyethylimidazoline and the 17 parts by weight of dodecyldimethylbenzyl ammonium chloride into the reaction kettle, stir and heat to 45°C,

[0116] Then add the 1 weight part of hydroxyethylidene diphosphonic acid and ...

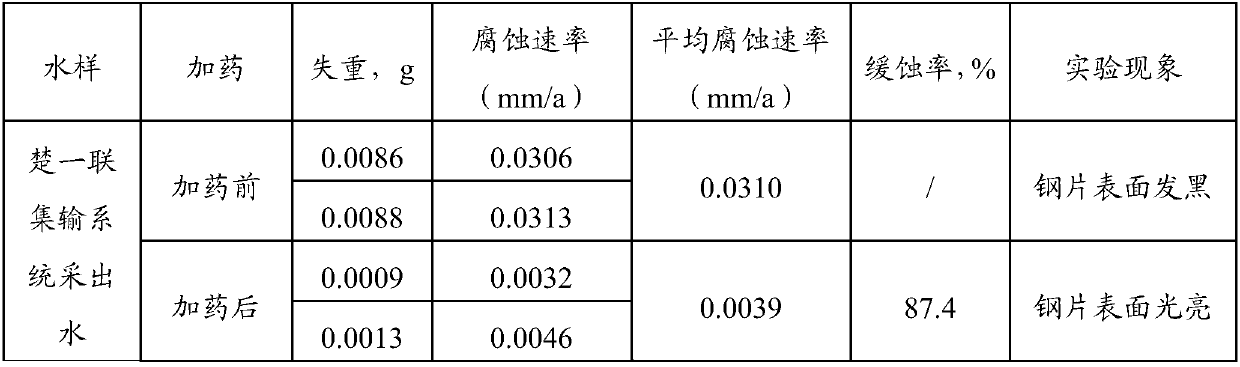

Embodiment 3

[0131] Embodiment 3 of the present invention provides a corrosion inhibitor and fungicide for oil fields.

[0132] Polymerized organic guanidines are prepared by the following steps:

[0133] In a four-necked flask equipped with a mechanical stirrer, a reflux condenser, a thermometer and an ammonia absorbing device, add 9 parts by weight of hexamethylenediamine diacetyl, 5.5 parts by weight of guanidine hydrochloride and 5.25 parts by weight of ethylene glycol in proportion , heated to 100°C, reacted for 4 hours, then raised the temperature to 180°C, and continued to react for 2 hours to obtain polymerized organic guanidine.

[0134] The preparation method of anti-corrosion fungicide for oil field:

[0135] First, add the 13 parts by weight of oleic acid-based hydroxyethylimidazoline and the 22 parts by weight of dodecyldimethylbenzyl ammonium chloride into the reaction kettle, stir and heat to 45°C,

[0136] Then add the 5 parts by weight of hydroxyethylidene diphosphonic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com