Application of fullerene methylene derivative I in perovskite solar cells, perovskite solar cell and preparation method thereof

A fullerene methylene, solar cell technology, applied in the field of solar cells, can solve the problems of high cost, lack of conditions for mass production, etc., and achieves increased grain size, easy purification, and reduced carrier migration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

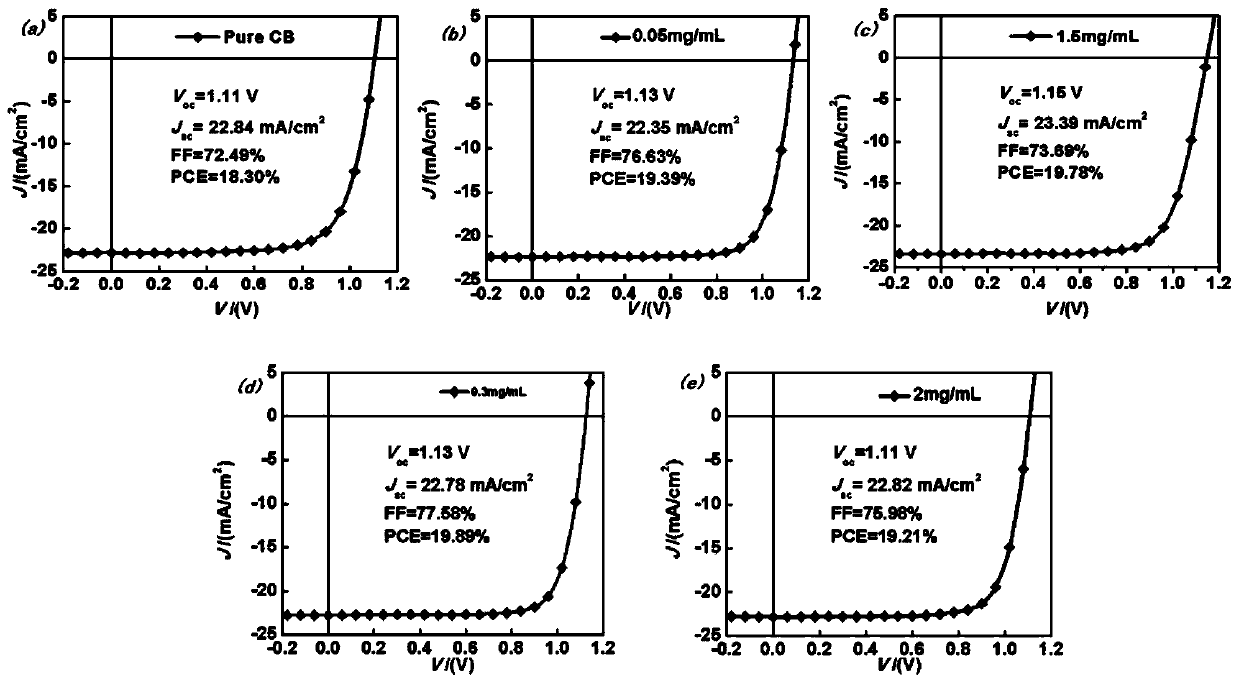

Embodiment 1

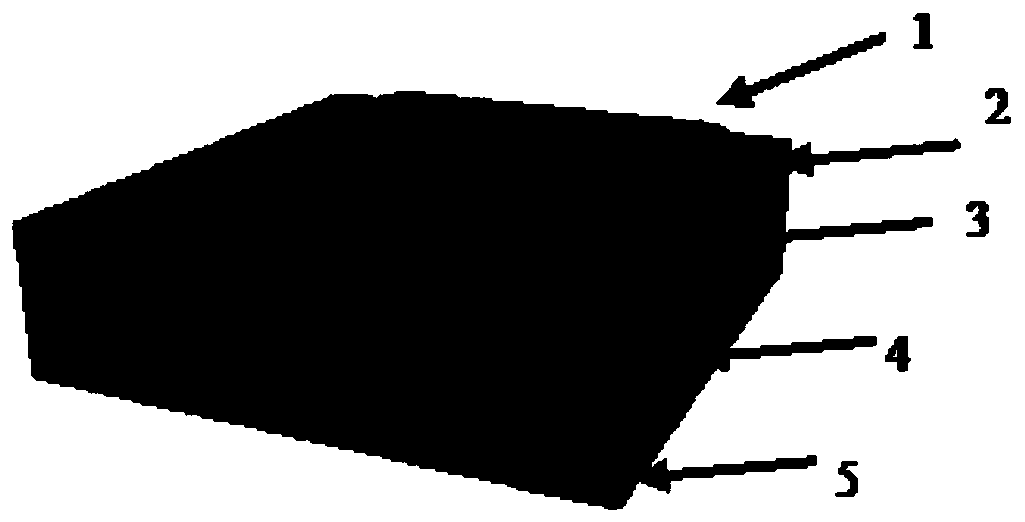

[0057] S1, the SnCl concentration of 0.1mg / mL 2 .2H 2 0 Ethanol solution was spin-coated on the ITO surface, the spin-coating condition was 2000r, the spin-coating time was 30s, the annealing was at 150°C for 30 minutes, and then at 180°C for 60 minutes.

[0058] S2, the type of perovskite active layer is (FAPbI 3 ) x (MAPbBr 3 ) 1-x , Dissolve the perovskite precursor in a mixed solution of DMF: DMSO=4:1, configure it into a 1.35M perovskite precursor solution, and use the spin-coating rotation speed of 6000r and the spin-coating time of 40s to reduce the calcium The titanium ore precursor was spin-coated onto the surface of the electron transport layer, and at the 20th second, 100 uL of a chlorobenzene (CB) solution of 0.05 mg / mL fullerene methylene derivative I was added dropwise. After the spin coating is finished, annealing is performed at 100°C for 60 minutes to obtain a perovskite layer doped with fullerene methylene derivative I on the surface.

[0059] S3. Spin-coating a s...

Embodiment 2

[0063] S1, spin-coating SnCl with a concentration of 0.1 mg / mL on the ITO surface 2 .2H 2 0 ethanol solution, spin coating conditions are 2000r, 30s. After spin coating is completed, annealed at 150°C for 30min and at 180°C for 60min.

[0064] S2, the type of perovskite active layer is (FAPbI 3 ) x (MAPbBr 3 ) 1-x , Dissolve the perovskite precursor in a mixed solution of DMF:DMSO=4:1, configure it into a 1.35M perovskite precursor solution, spin the perovskite precursor at a rotation speed of 6000r and a spin coating time of 40s Apply to the surface of the electron transport layer, and at the 20th second, drop 100uL of a 2mg / mL fullerene methylene derivative I in chlorobenzene (CB) solution. After the spin coating is finished, annealing is performed at 100°C for 60 minutes.

[0065] S3. Spiro-OMeTAD solution (doped with Li-TFSI and tBP) at a concentration of 80 mg / mL was spin-coated on the surface of the perovskite and oxidized in air for 24 hours.

[0066] S4. Evaporate 8nm silve...

Embodiment 3

[0069] S1, spin-coating SnCl with a concentration of 0.1 mg / mL on the ITO surface 2 .2H 2 0 ethanol solution, spin coating conditions are 2000r, 30s, and annealing at 150℃ for 30min, and annealing at 180℃ for 60min.

[0070] S2, the type of perovskite active layer is (FAPbI 3 ) x (MAPbBr 3 ) 1-x , Dissolve the perovskite precursor in a mixed solution of DMF:DMSO=4:1, configure it into a 1.35M perovskite precursor solution, and apply the perovskite to the spin-coating conditions with a rotation speed of 6000r and a spin coating time of 40s. The precursor was spin-coated on the surface of the electron transport layer, and 100 uL of chlorobenzene anti-solvent solution was added dropwise at the 20th second. After the spin coating is finished, annealing is performed at 100°C for 60 minutes.

[0071] 30 uL of chlorobenzene (CB) solution of fullerene methylene derivative I with a concentration of 0.3 mg / mL was spin-coated on the surface of the perovskite active layer under the spin coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com