Phosphorus-doped porous carbon material, preparation method thereof and application of phosphorus-doped porous carbon material in coating diaphragm for lithium-sulfur battery

A porous carbon material and lithium-sulfur battery technology, applied in the field of electrochemistry, can solve the problems that hinder the application of rechargeable Li-S batteries, reduce the Coulombic efficiency, and cell self-discharge, and achieve the suppression of shuttle effect, suppression of self-discharge, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of β-carbonyl cyclodextrin binder: First, dissolve 2.0 g of β-cyclodextrin in 5 mL of H 2 o 2 The solution was kept at 80° C. for 24 hours to remove the solvent, and then transferred to a vacuum drying oven at 80° C. for 24 hours to obtain the β-carbonyl cyclodextrin binder.

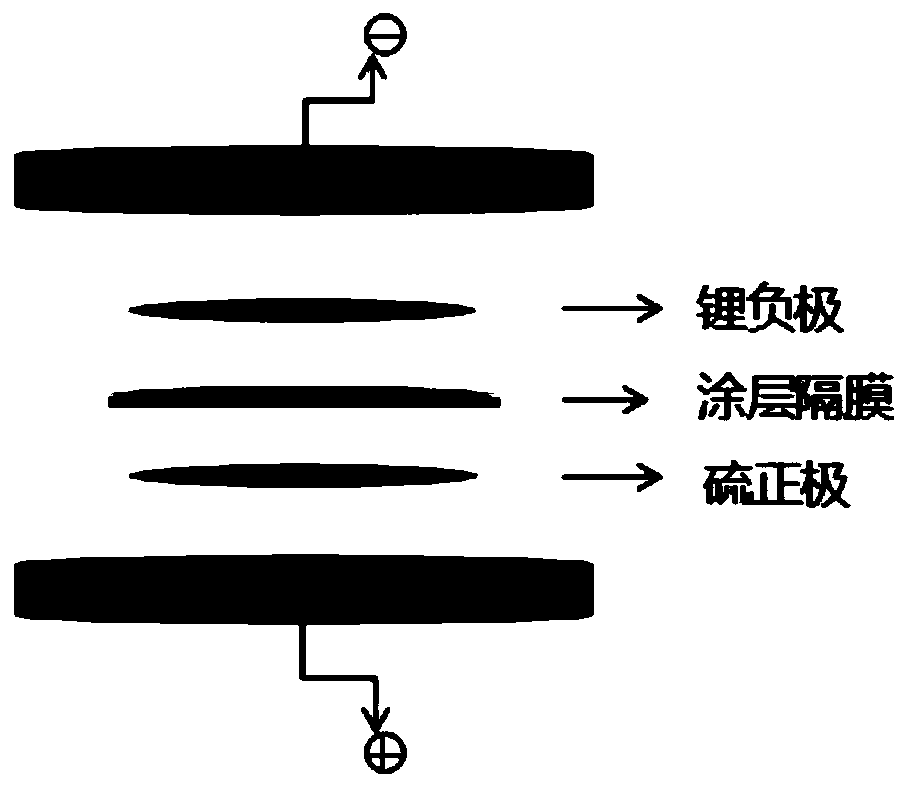

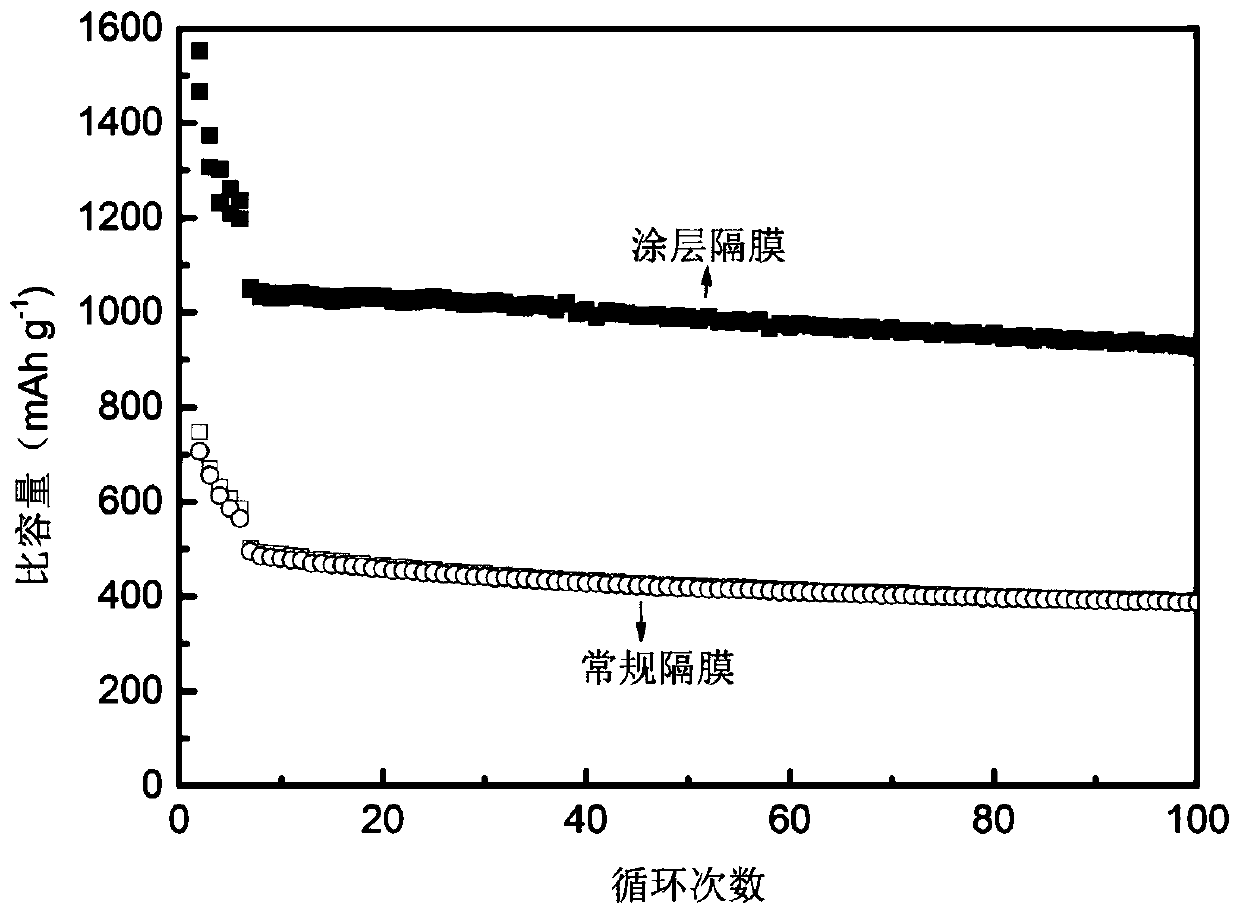

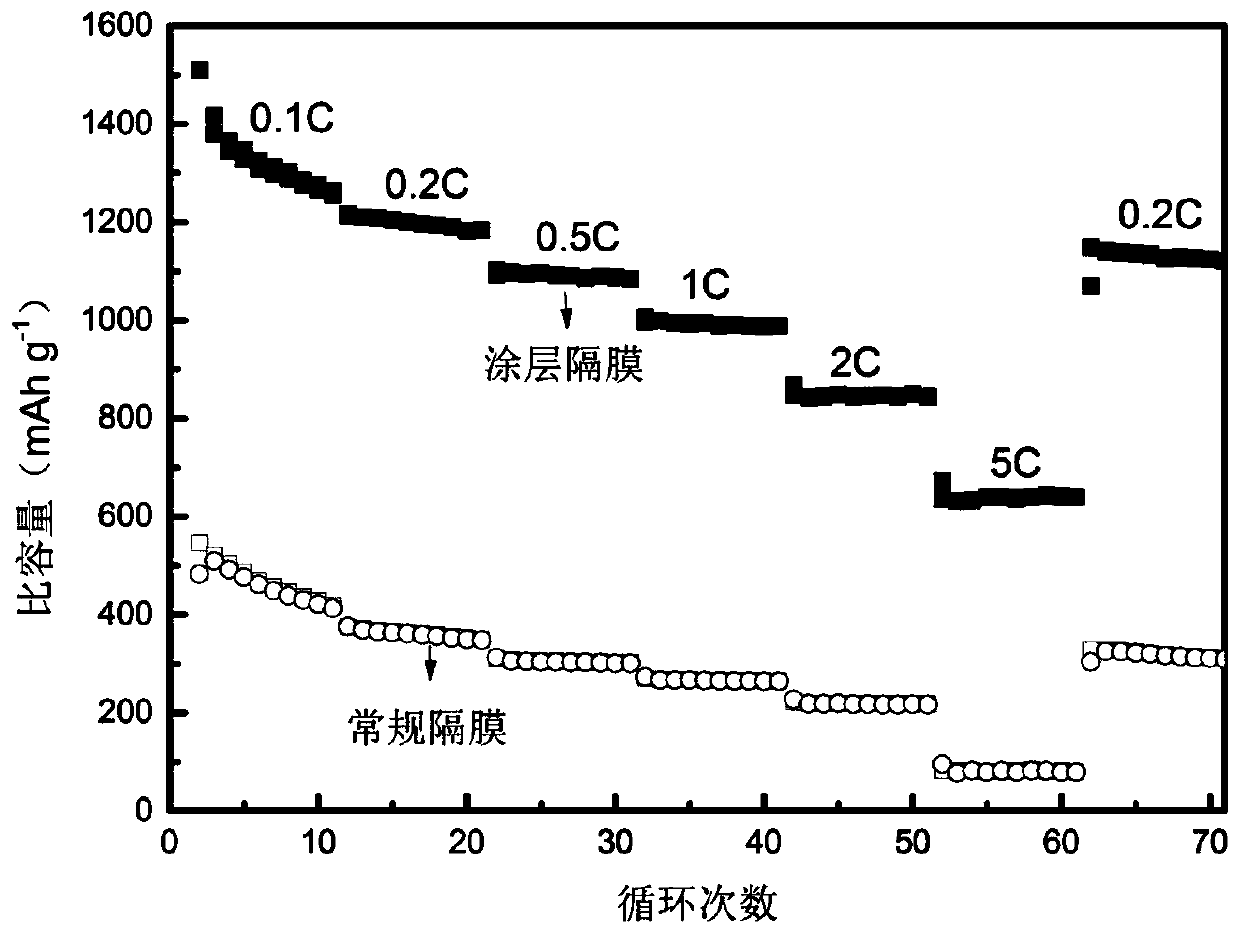

[0035] Preparation of coated separators for lithium-sulfur batteries: first dehydrate 0.15M sucrose solution in a hydrothermal kettle at 190°C, and then further carbonize in argon in a tube furnace at 900°C. For a 500mg carbon sample, add 650μL of 2.0M Co(NO 3 ) 2 ·6H 2 The solution of O was dried overnight at 100 °C to obtain Co-C. Then add phytic acid, phytic acid: the mass ratio of carbon sample=5:1, after drying at 85 ℃, put the sample in N 2 Under the atmosphere, the rate was increased to 800°C at a rate of 3°C / min and kept for 1 hour, then 1.0M HCl solution was used for 12 hours to dissolve the residual Co salt, and finally dried at 80°C to obtain a phosphorus-doped porous c...

Embodiment 2

[0040] Preparation of β-carbonyl cyclodextrin binder: First, dissolve 2.0 g of β-cyclodextrin in 5 mL of H 2 o 2 The solution was kept at 80° C. for 24 hours to remove the solvent, and then transferred to a vacuum drying oven at 80° C. for 24 hours to obtain the β-carbonyl cyclodextrin binder.

[0041] Preparation of coated separators for lithium-sulfur batteries: First, dehydrate 0.15M sucrose solution in a hydrothermal kettle at 190°C, and then further carbonize in argon in a tube furnace at 1000°C. For a 500mg carbon sample, add 650μL of 2.0M Co(NO 3 ) 2 ·6H 2 O solution, dried overnight at 100°C. Then add phytic acid, phytic acid: the mass ratio of carbon sample=3:1, after drying at 85 ℃, put the sample in N 2 Under the atmosphere, the rate was raised to 800°C at a rate of 3°C / min for calcination and pyrolysis and kept for 1 hour, then 1.0M HCl solution was used for 12h to dissolve the residual Co salt, and finally dried at 80°C to obtain a phosphorus-doped porous car...

Embodiment 3

[0044] Preparation of β-carbonyl cyclodextrin binder: First, dissolve 2.0 g of β-cyclodextrin in 5 mL of H 2 o 2 The solution was kept at 80° C. for 24 hours to remove the solvent, and then transferred to a vacuum drying oven at 80° C. for 24 hours to obtain the β-carbonyl cyclodextrin binder.

[0045] Preparation of coated separators for lithium-sulfur batteries: first dehydrate 0.15M sucrose solution in a hydrothermal kettle at 190°C, and then further carbonize in argon in a tube furnace at 900°C. For a 500mg carbon sample, add 650μL of 2.0M Co(NO 3 ) 2 ·6H 2 O solution, dried overnight at 100°C. Then add phytic acid, phytic acid: carbon sample = 7: 1 mass ratio, dry the sample at 85°C 2 Under the atmosphere, the rate was increased to 800°C at a rate of 3°C / min and kept for 1 hour, then 1.0M HCl solution was used for 12 hours to dissolve the residual Co salt, and finally dried at 80°C to obtain a phosphorus-doped porous carbon material, the specific surface area 278m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com