Method for recycling lithium nickel cobalt manganese oxide ternary positive electrode material of retired lithium-ion power battery

A technology for nickel-cobalt lithium manganate and lithium-ion batteries, which is applied in the field of recycling and reuse of nickel-cobalt lithium manganate ternary positive electrode materials for retired lithium-ion power batteries, and can solve the problems of complicated operation, high cost and low metal recovery rate of the treatment method. problem, to achieve the effect of simple recovery method process, less compounds, and high purity of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

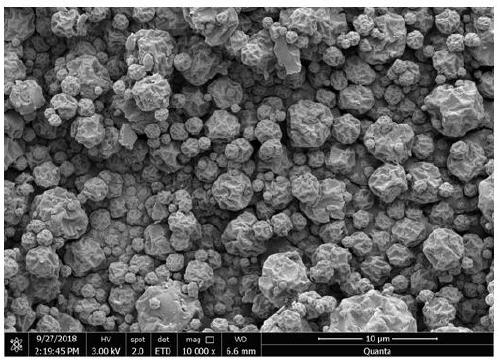

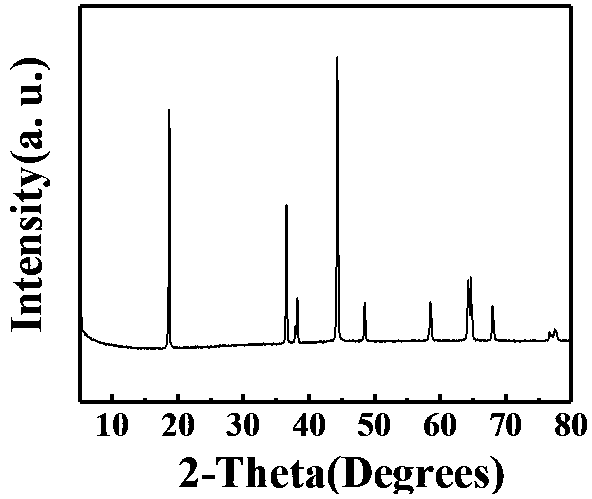

[0027] In this embodiment, the method for recycling the nickel-cobalt lithium manganate ternary positive electrode material of the decommissioned lithium-ion power battery comprises the following steps:

[0028] (1) Cut the positive pole piece of the waste nickel-cobalt-lithium manganese oxide battery obtained from dismantling into pieces of about 2*3cm in size;

[0029] (2) Configure a dilute sulfuric acid solution with a concentration of 0.5mol / L, put in crushed positive electrode pieces according to the ratio of solid to liquid ratio of 1:10, mechanical stirring speed of 180r / min, and add ultrasonic cleaning, react for about 30 minutes, and sort out Aluminum foil, then add sulfuric acid with 10% of the pole piece weight, heat at 50°C and stir for 40 minutes, then add ammonia water dropwise to the reaction solution to adjust the pH of the solution to 5, filter and wash, add barium acetate solution dropwise to the filtrate until complete precipitation , to obtain a transparen...

Embodiment 2

[0033] In this embodiment, the method for recycling the nickel-cobalt lithium manganate ternary positive electrode material of the decommissioned lithium-ion power battery comprises the following steps:

[0034] (1) Cut the positive pole piece of the waste nickel-cobalt-lithium manganese oxide battery obtained from dismantling into pieces of about 2*3cm in size;

[0035] (2) Configure a dilute sulfuric acid solution with a concentration of 0.4mol / L, put in the broken positive electrode sheet according to the ratio of solid to liquid ratio of 1:12, mechanical stirring speed of 180r / min, and add ultrasonic cleaning, react for about 50 minutes, and sort out Aluminum foil, then add sulfuric acid with 10% of the pole piece weight, heat at 60°C and stir for 40 minutes, then add ammonia water dropwise to the reaction solution to adjust the pH of the solution to 5, filter and wash, add barium acetate solution dropwise to the filtrate until complete precipitation , to obtain a transpar...

Embodiment 3

[0039] In this embodiment, the method for recycling the nickel-cobalt lithium manganate ternary positive electrode material of the decommissioned lithium-ion power battery comprises the following steps:

[0040](1) Cut the positive pole piece of the waste nickel-cobalt-lithium manganese oxide battery obtained from dismantling into pieces of about 2*3cm in size;

[0041] (2) Configure a dilute sulfuric acid solution with a concentration of 0.6mol / L, put in the broken positive electrode sheet according to the ratio of solid to liquid ratio of 1:9, mechanical stirring speed of 200r / min, and add ultrasonic cleaning, react for about 30 minutes, and sort out Aluminum foil, then add sulfuric acid with 10% of the pole piece weight, heat at 70°C and stir for 40 minutes, then add ammonia water dropwise to the reaction solution to adjust the pH of the solution to 5, filter and wash, add barium acetate solution dropwise to the filtrate until complete precipitation , to obtain a transparen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com