Modified boron nitride composite material, preparation method thereof and side sealing plate

A composite material, boron nitride technology, applied in the field of modified boron nitride composite material and its preparation, side sealing plate, can solve the problems of short service life, poor thermal shock resistance, prone to cracks, etc., and achieve oxidation resistance Good, good thermal shock resistance, and the effect of reducing crystal plane cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method for the above-mentioned modified boron nitride composite material, comprising the following steps:

[0035] Grinding and mixing boron nitride, zirconia, sialon, silicon carbide and additives to obtain mixed powder;

[0036] The mixed powder is hot-pressed and sintered to obtain a modified boron nitride composite material.

[0037] The invention grinds and mixes boron nitride, zirconium oxide, sialon, silicon carbide and additives to obtain mixed powder.

[0038] The method of mixing is not particularly limited in the present invention, and a mixing method well known to those skilled in the art can be selected. The method of grinding and mixing is not particularly limited in the present invention, and a grinding and mixing method well known to those skilled in the art can be selected, such as ball milling. In the present invention, the particle size of the mixed powder obtained after grinding and mixing is prefer...

Embodiment 1

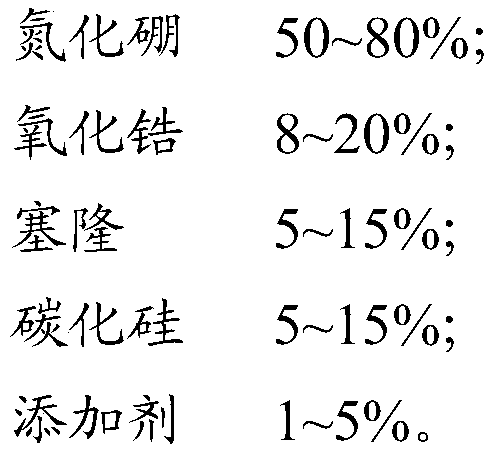

[0059] Raw materials and their mass percentages

[0060]

[0061] After mixing the raw materials in the above mass percentages, ball milling for 12 hours, passing through a 200-mesh sieve to obtain the mixture, and then using an isostatic press to granulate (form particles with a particle size ≤ 5mm), and then load the mold for hot pressing and sintering. The hot pressing and sintering molding conditions are as follows: from room temperature to 900°C at 15°C / min, then to 1400°C at 5°C / min, and start filling with N 2 , rise to 1600°C at 5°C / min and pressurize to 5MPa, heat and hold for 30 minutes, rise to 1700°C at 4°C / min, pressurize to 8MPa, hold and hold for 60 minutes, rise to 1850°C at 3°C / min , and pressurized to 14MPa, heat preservation and pressure holding for 60min, pressure release and natural cooling, and the modified boron nitride composite material was obtained from the mold. The modified boron nitride composite was tested with a density of 2.65g / cm 3 , The Le...

Embodiment 2

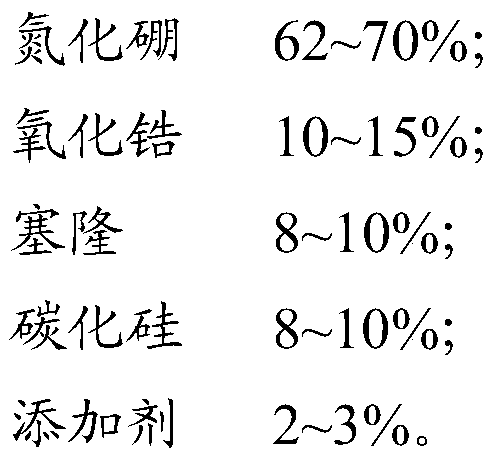

[0066] Raw materials and their mass percentages

[0067]

[0068] After mixing the raw materials in the above mass percentages, ball mill them for 12 hours, and pass through a 200-mesh sieve to obtain a mixture, then use an isostatic press to granulate, and then install a mold for hot-pressing sintering molding. The hot-pressing sintering molding conditions are as follows: Room temperature rises to 800°C at 10°C / min, then rises to 1500°C at 8°C / min, and starts filling with N 2 , rise to 1550°C at 5°C / min and pressurize to 4MPa, heat and hold for 40 minutes, rise to 1750°C at 4°C / min, pressurize to 10MPa, heat hold and hold for 70 minutes, rise to 1950°C at 3°C / min , and pressurized to 16MPa, heat preservation and pressure holding for 70min, the pressure was released and the temperature was naturally lowered, and the modified boron nitride composite material was obtained from the mold. The modified boron nitride composite was tested with a density of 2.72g / cm 3 , The Leeb ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com