Composite ink, preparation method thereof, and device

An ink and mixed solvent technology, applied in the field of composite ink and its preparation, can solve the problems of light quenching of luminescent materials, difficulty in ink preparation, damage and the like, and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

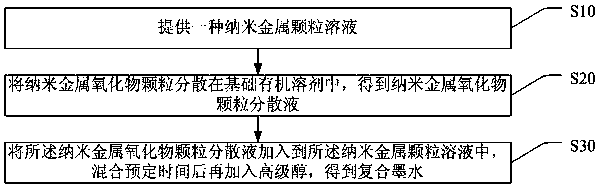

[0030] See figure 1 , figure 1 It is a flowchart of a preferred embodiment of a method for preparing a composite ink according to the present invention, as shown in the figure, which includes the steps:

[0031] S10. Provide a nano metal particle solution;

[0032] S20: Disperse the nano metal oxide particles in a basic organic solvent to obtain a nano metal oxide particle dispersion;

[0033] S30. Adding the nano metal oxide particle dispersion to the nano metal particle solution, mixing for a predetermined time, and then adding higher alcohol to obtain a composite ink.

[0034] Specifically, inkjet printing technology, as an effective way for the industrialization and large-scale production of existing thin film display devices, can significantly increase the production capacity of thin film display devices and reduce their production costs. However, because inkjet printing equipment requires high physical and chemical properties of the ink, such as suitable boiling point, viscosity...

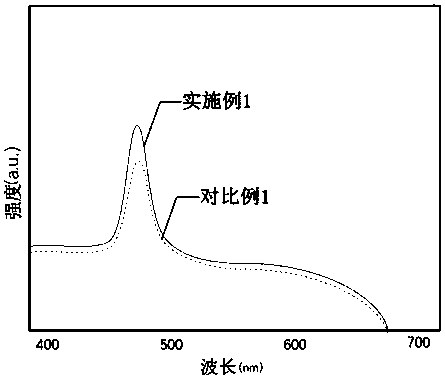

Embodiment 1

[0063] A composite ink includes nano zinc oxide particles and nano silver particles dispersed in ethanol and 1,4-butanediol. The preparation method of the composite ink includes:

[0064] Prepare 100ml of ethanol solution of nano zinc oxide particles with a concentration of 20mg / ml;

[0065] Prepare 10ml of ethanol solution of silver nanoparticles with a concentration of 3mg / ml;

[0066] Under vigorous stirring, add dropwise the ethanol solution of nano silver particles to the ethanol solution of nano zinc oxide particles, and continue stirring for 24 hours at room temperature to obtain nano silver particles-nano zinc oxide composite ink;

[0067] The nano-silver particle-nano-zinc oxide composite ink was washed three times with propanol, and then redispersed with ethanol, and 50ml of 1,4-butanediol was added dropwise to obtain a nanometer containing 1,4-butanediol. Silver particles-nano zinc oxide composite ink, the viscosity of the composite ink measured at 25° C. is 8.32 cP.

[0068...

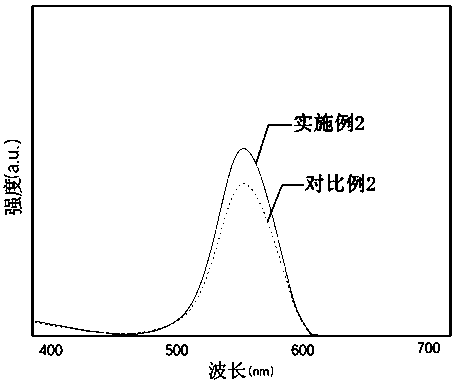

Embodiment 2

[0074] A composite ink includes nano zinc oxide particles and nano gold particles dispersed in ethanol and 1,3-butanediol. The preparation method of the composite ink includes:

[0075] Prepare 100ml ethanol solution of nano zinc oxide particles with a concentration of 16mg / ml;

[0076] Prepare 10ml of ethanol solution of gold nanoparticles with a concentration of 20mg / ml;

[0077] Under vigorous stirring, add the ethanol solution of gold nanoparticles to the ethanol solution of nano zinc oxide particles dropwise, and continue stirring for 24 hours at room temperature to obtain nano gold particles-nano zinc oxide composite ink;

[0078] Wash the nano-gold particles-nano-zinc oxide composite ink 3 times with propanol, then redisperse it with ethanol, and add 50ml of 1,3-butanediol drop by drop to obtain nanometers containing 1,3-butanediol. Gold particle-nano-zinc oxide composite ink, the viscosity of the composite ink measured at 25° C. is 8.50 cP.

[0079] The above-mentioned nano-gol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com