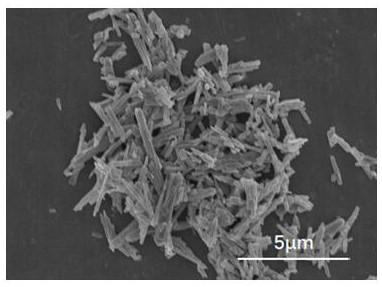

Preparation method of a sheet-shaped V3S4 electrocatalyst and an application thereof of electrocatalytic performance

A V3S4, electrocatalyst technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of limited global resources and difficulty in meeting energy demand, and achieve the effect of uniform chemical composition, low cost, high purity and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Weigh 4 mmol of oxalic acid and dissolve it in 40 mL of deionized water, add two drops of ammonia water, and stir magnetically for 30 minutes to obtain solution A; weigh 2 mmol of V 2 o 5 Dissolve in solution A, stir magnetically for 30 min to obtain solution B.

[0025] Step 2: Pour the prepared solution B into the reaction polytetrafluoroethylene lining, the filling ratio of the reactor is 80%, and put the inner lining into the outer kettle, and place it in the oven after fixing it, and react The condition is to keep warm at 180°C for 24h.

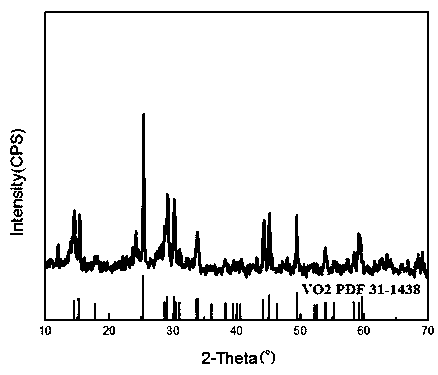

[0026] Step 3: After the hydrothermal reaction is completed, the hydrothermal kettle is naturally cooled to room temperature, and the reaction liquid is poured out and washed 3 times with deionized water and absolute ethanol. After suction filtration, the sample is collected and dried under vacuum at 60°C for 24 hours to obtain VO 2 nanomaterials.

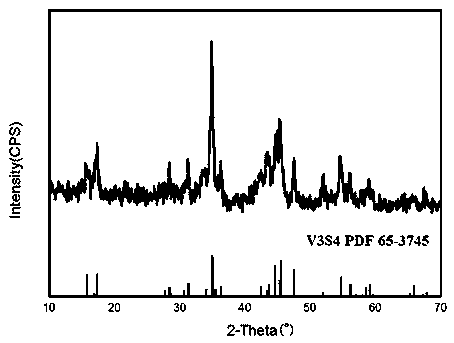

[0027] Step 4: Control the molar ratio of vanadium oxide and thioaceta...

Embodiment 2

[0033] Step 1: Weigh 5mmol of oxalic acid and dissolve it in 40mL of deethylene glycol, add two drops of ammonia water dropwise, and stir magnetically for 30min to obtain solution A; weigh 2mmol of V 2 o 5 Dissolve in solution A, stir magnetically for 30 min to obtain solution B.

[0034] Step 2: Pour the prepared solution B into the reaction polytetrafluoroethylene lining, the filling ratio of the reactor is 80%, and put the inner lining into the outer kettle, and place it in the oven after fixing it, and react The condition is to keep warm at 200°C for 24h.

[0035] Step 3: After the hydrothermal reaction is completed, the hydrothermal kettle is naturally cooled to room temperature, and the reaction liquid is poured out and washed 3 times with deionized water and absolute ethanol. After suction filtration, the samples were collected and dried under vacuum at 80° C. for 12 hours to obtain VO2 nanomaterials.

[0036] Step 4: Control the molar ratio of vanadium oxide and sub...

Embodiment 3

[0041] Step 1: Weigh 5 mmol of oxalic acid and dissolve it in 40 mL of deionized water, add four drops of ammonia water, and stir magnetically for 30 minutes to obtain solution A; weigh 2 mmol of V 2 o 5 Dissolve in solution A, stir magnetically for 30 min to obtain solution B.

[0042] Step 2: Pour the prepared solution B into the reaction polytetrafluoroethylene lining, the filling ratio of the reactor is 80%, and put the inner lining into the outer kettle, and place it in the oven after fixing it, and react The condition is to keep warm at 180°C for 24h.

[0043] Step 3: After the hydrothermal reaction is completed, the hydrothermal kettle is naturally cooled to room temperature, and the reaction liquid is poured out and washed 3 times with deionized water and absolute ethanol. After suction filtration, the sample is collected and dried under vacuum at 40°C for 24 hours to obtain VO 2 nanomaterials.

[0044] Step 4: Control the molar ratio of vanadium oxide and thioacet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com