Graphene crystal film with high conductivity and preparation method thereof

A graphene, high conductivity technology, applied in the direction of graphene, cable/conductor manufacturing, conductors, etc., can solve the problems of difficult scale, high cost of graphene, low output, etc., to achieve easy raw materials, simple operation, high conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

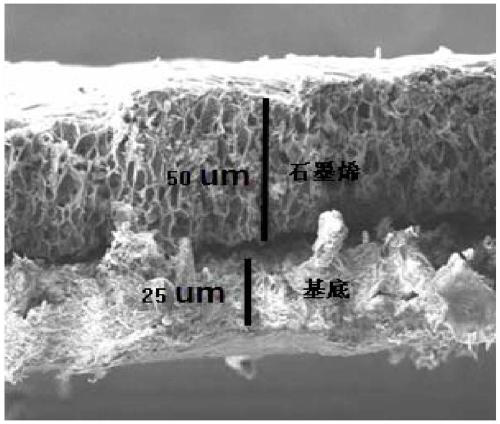

[0043] see figure 1 , the present embodiment discloses a method for preparing a graphene crystal film with high electrical conductivity, which has a high efficiency in the conversion process of organic polymers to graphene induced by micro-nano-scale metal particle catalysts and laser irradiation, and the product graphene The crystal quality is high, and at the same time, due to the reduction of graphene, the oxidation of metal particles is avoided, so that the reaction can be carried out in an air atmosphere, and the final product graphene crystal film is still combined with metal particles, which can be graphene crystals The thin film provides a large number of free electrons, combined with the extremely high electron mobility of graphene itself, it can finally achieve extremely high electrical conductivity.

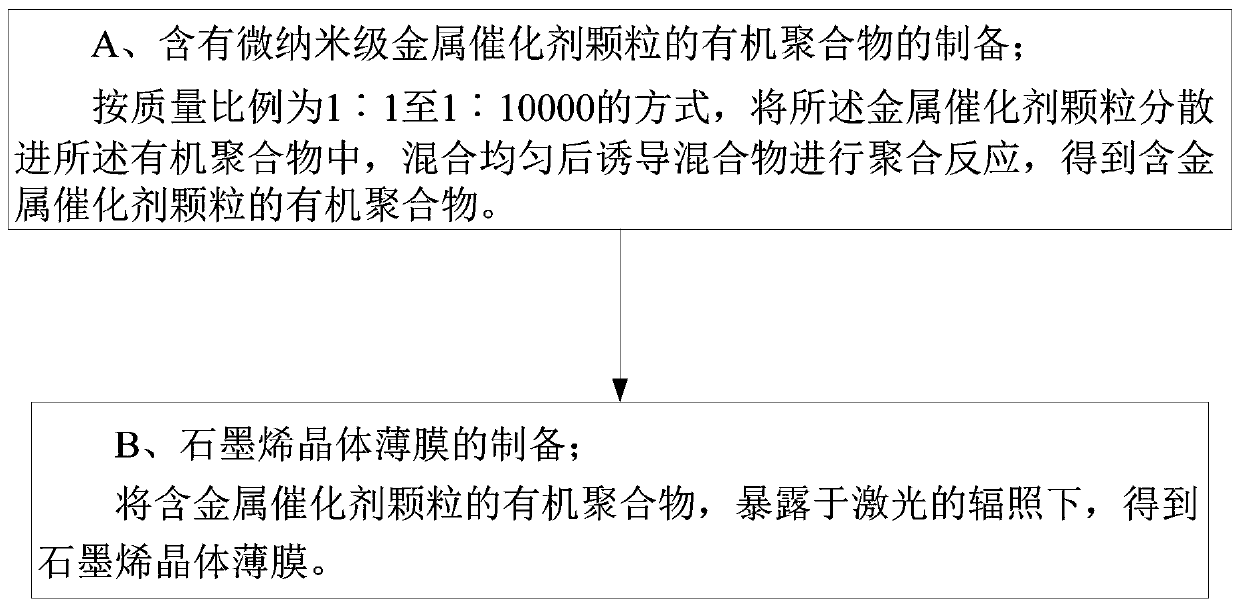

[0044] The preparation method of graphene crystal film comprises the following steps:

[0045] a. Preparation of organic polymers containing micro-nano-scale metal ca...

Embodiment 2

[0057] According to the description of the embodiment, copper particles with an average diameter of 20 nm are selected as the catalyst, and polyimide is selected as the organic polymer. First, use pyromellitic dianhydride and 4,4'-diaminodiphenyl ether as synthetic raw materials to prepare the precursor of polyimide, that is, polyamic acid solution: measure 4mmol / L 4,4'-diaminodiphenyl ether Dissolve diphenyl ether in 15ml / L N-methylpyrrolidone, add 2mmol / L pyromellitic dianhydride, add the remaining 2mmol / L pyromellitic dianhydride after it is fully dissolved for 20min, and keep stirring for 30min, the solution Become viscous to obtain a polyamic acid solution; then, add copper particles with a diameter of 20nm to 50nm to the above polyamic acid solution to form a mixed solution, the mass fraction of copper particles is 1% to 2%, and stir for 60min.

[0058] In this example, first use pyromellitic dianhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA) as synthetic raw materi...

Embodiment 3

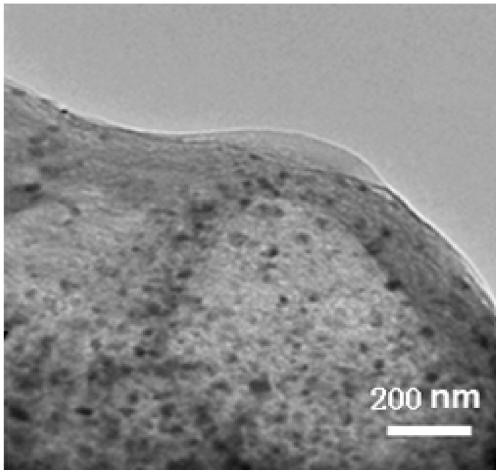

[0062] The preparation method of the graphene crystal thin film in this embodiment is the same as that in Embodiment 2, the mass fraction of copper nanoparticles added is 2%, and the rest of the conditions are the same as in Embodiment 2. The conductivity of the prepared graphene crystal film can be as high as 5.1×10 7 S / m.

[0063] Figure 6 It is a transmission electron microscope photo of the graphene crystal thin film prepared in this embodiment. It can be seen from the figure that the copper nanoparticles are more densely distributed in the graphene, and the content is larger, so the conductivity is larger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com