Thixotropic solvent-free epoxy coating and preparation method thereof

An epoxy coating, solvent-free technology, applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high hardness, poor flexibility, affecting adhesion, difficult to achieve, etc., to achieve good toughening modification effect, ensuring strength, and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

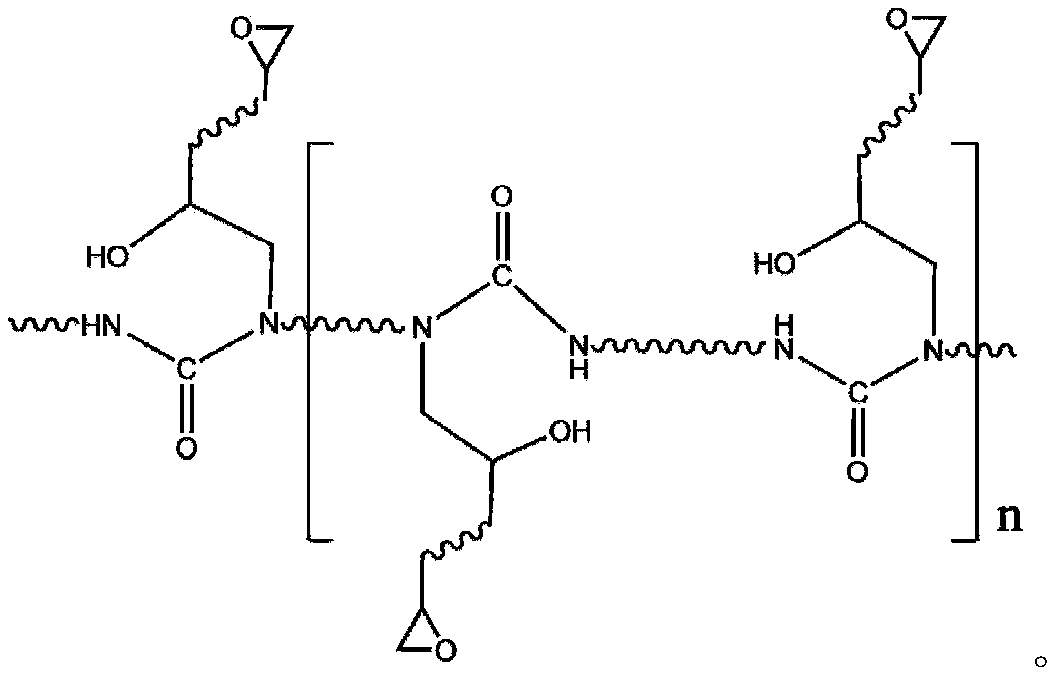

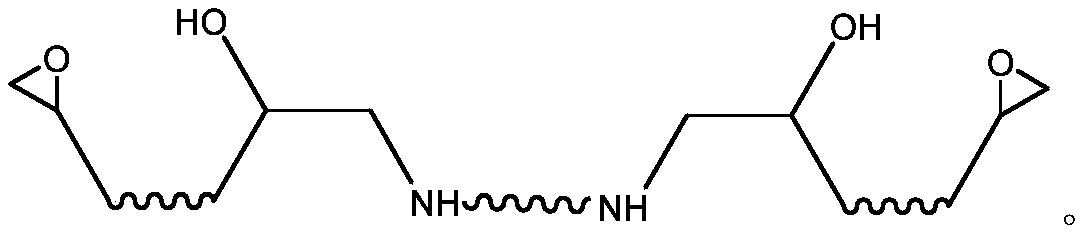

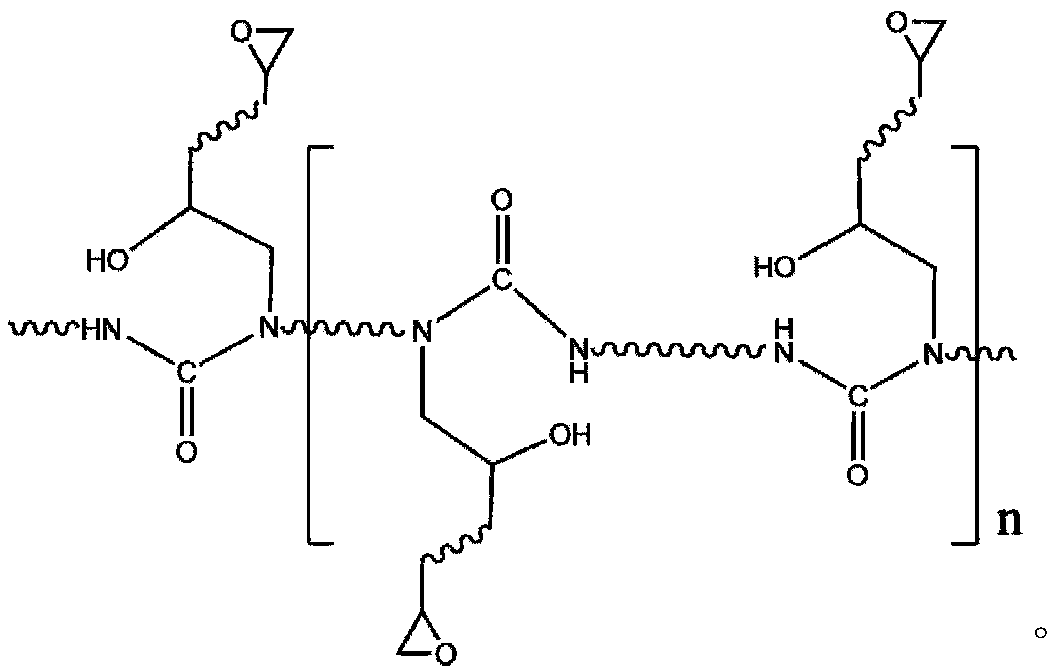

Image

Examples

Embodiment 1

[0024] First, mix 20 parts of ethylene glycol diglycidyl ether with 15 parts of 3,3'-diethyl-4,4'-diaminodiphenylmethane, stir well, and then keep it at 60°C for 2 hours, then lower it to room temperature to obtain the improved Permanent epoxy resin for use; mix 100 parts of epoxy resin E51 with another 15 parts of ethylene glycol diglycidyl ether, and then add 0.5 parts of dispersant BNK-NSF163, 0.5 parts of dispersant BNK-NSF161, defoamer Tech 1.5 parts of -430, 1 part of carbon black, 20 parts of titanium dioxide, 20 parts of precipitated barium sulfate, 50 parts of gray micaceous iron oxide, after dispersion, grind to a fineness of 80 μm; then add the previous modified epoxy resin, stir evenly, Adjust the rotational speed to 200rpm, add 40 parts of isocyanate prepolymer, stir evenly, and then discharge the material to obtain a thixotropic solvent-free epoxy coating.

[0025] Among them, 20 parts of ethylene glycol diglycidyl ether is a binary epoxy resin, 3,3'-diethyl-4,4'...

Embodiment 2

[0027] First mix 20 parts of ethylene glycol diglycidyl ether with 20 parts Mix D-400, stir well, keep warm at 60°C for 3 hours, lower to room temperature to obtain modified epoxy resin for use; mix 100 parts of epoxy resin E51 with 10 parts of butyl glycidyl ether and 10 parts of polypropylene glycol diglycidyl ether Mix evenly, then add 0.5 parts of dispersant BNK-NSF163, 1.0 parts of defoamer Tech-430, 15 parts of red iron oxide, 80 parts of red mica iron oxide, and 30 parts of barite powder, disperse and grind to a fineness of 65 μm Then add the modified epoxy resin in front, and after stirring evenly, adjust the rotating speed to 300 rpm, add 30 parts of isocyanate prepolymer, stir evenly, and then discharge the material to obtain a thixotropic solvent-free epoxy coating.

[0028] Wherein, ethylene glycol diglycidyl ether is a binary epoxy resin, D-400 is binary polyether amine, butyl glycidyl ether and polypropylene glycol diglycidyl ether are reactive epoxy diluents,...

Embodiment 3

[0030] First mix 25 parts of epoxy resin E51 with 6.5 parts Mix D-230, stir well, keep warm at 70°C for 1 hour, lower to room temperature to obtain modified epoxy resin for later use; mix another 100 parts of epoxy resin E51 with 15 parts of C12~C14 alkyl glycidyl ether, and then Add 0.5 parts of dispersant BNK-NSF163, 2.0 parts of defoamer Tech-430, 15 parts of iron oxide red, 10 parts of talc powder, and 100 parts of barite powder, and grind to a fineness of 40 μm after dispersion; then add the previous modified ring Oxygen resin, after stirring evenly, add 10 parts of isocyanate prepolymer when the rotation speed is adjusted to 300rpm, stir evenly, and then discharge, to obtain a thixotropic solvent-free epoxy coating.

[0031] Among them, 25 parts of epoxy resin E51 is binary epoxy resin, D-230 is binary polyether amine, C12~C14 alkyl glycidyl ether is active epoxy diluent, BNK-NSF163 is dispersant, Tech-430 is defoamer, iron oxide red, talc powder and barite powder Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com