Production of novel indigo dye Corynebacterium glutamicum and its construction method and application

A technology of Corynebacterium glutamicum and indigo, applied in the biological field, can solve the problems of E.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Construction of recombinant Corynebacterium glutamicum C.glutamicum ATCC 13032-(BpsA-SFP)

[0031] Using the genome of S. lavendulae as the template, the bpsA gene was amplified with the upstream and downstream primers of bpsA-F and bpsA-R, and the genome of B. subtilis was used as the template, sfp-F and sfp -R upstream and downstream primers amplify the sfp gene, using the pEC-XK99E plasmid as a template, the vector fragment pECbone is amplified with two pairs of upstream and downstream primers, pECbone1-F and pECbone1-R and pECbone2-F and pECbone2-R, respectively. By introducing a homologous recombination sequence of 20bp at the 5' end of the primer, the amplification products must have completely identical sequences (15bp-20bp) capable of mutual homologous recombination. After mixing in a certain proportion, in Exnase TM Under the catalysis of E.coli, it only takes 30 minutes to transform into E.coli JM109. The recombinant expression plasmid pEC-XK99E-(Bp...

Embodiment 2

[0035] Example 2 Extraction and analysis of indigo dye

[0036] After collecting the cells, add 10 mg / mL dimethyl sulfoxide (DMSO), break the cells by ultrasonication, centrifuge at 6000 rpm for 15 min, place the supernatant in a new 50 mL centrifuge tube and centrifuge again until the centrifuge tube The sterile body was centrifuged down. Filter the supernatant through a 0.2 μM microporous membrane, add 5 times the volume of ultrapure water with DMSO to the filtered supernatant, and centrifuge the mixture of ultrapure water and bacterial liquid at 23°C at 12,000 rpm for 1 h, and discard. The supernatant was washed with ultrapure water, and then the bacteria dissolved in ultrapure water were evaporated to dryness with a rotary evaporator. Weigh 0.02 g of evaporated indigoidine powder, dissolve it with deuterated dimethyl sulfoxide (DMSO-d6), and centrifuge it with a 1.5 mL centrifuge tube at 23°C and 12,000 rpm for 15 min. ( 1 H-NMR) detection and analysis of the chemical s...

Embodiment 3

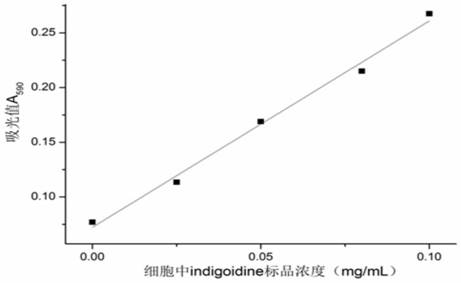

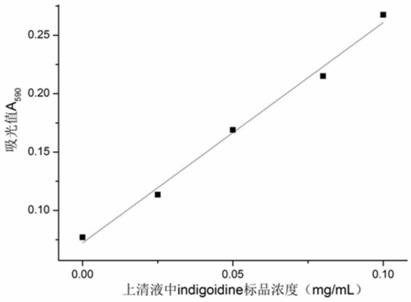

[0037] The preparation of embodiment 3 indigo dye standard curve

[0038] Dissolve 1 mg of purified indigoidine in 1 mL of dimethyl sulfoxide (DMSO) to prepare an indigoidine solution with a concentration of 1 mg / mL. This standard solution was serially diluted to different concentrations: 0 mg / mL, 0.025 mg / mL, 0.05 mg / mL, 0.08 mg / mL, 0.10 mg / mL. Use a spectrophotometer to detect the absorbance of the above five standard solutions with different concentrations at a wavelength of 600 nm. Taking the concentration of indigoidine as the abscissa and the absorbance as the ordinate, the standard curve of indigoidine was obtained by linear fitting. Since both the cells and the supernatant after fermentation contained indigoidine, the concentration curves of indigoidine in the cells and supernatants were drawn respectively. Standard curve R of indigoidine standard in bacteria 2 =0.996, the standard curve R of the indigoidine standard in the supernatant 2 =0.992, the linearity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com