Ore leaching method of weathered crust ion-adsorption type rare earth ore and rare earth product

A weathering crust elution type, rare earth ore technology, applied in the direction of improving process efficiency, can solve the problems of increased consumption of precipitant, large amount of rare earth leaching liquid, heavy hydrometallurgy work load, etc., to shorten the production cycle and improve the rare earth and impurity ion concentration, reducing the effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

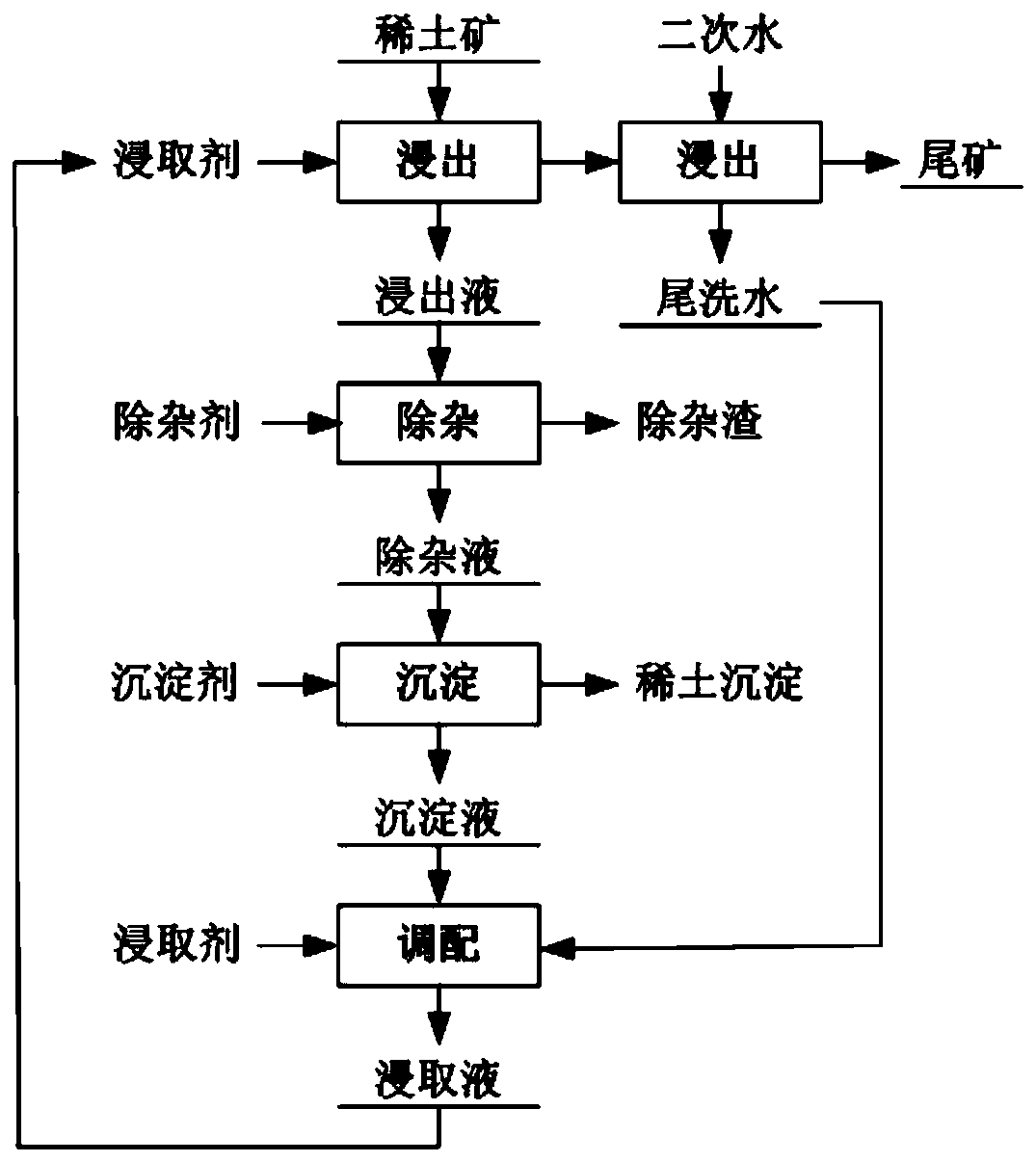

Method used

Image

Examples

Embodiment 1

[0039] S1. Leaching weathering crust leaching type rare earth ore

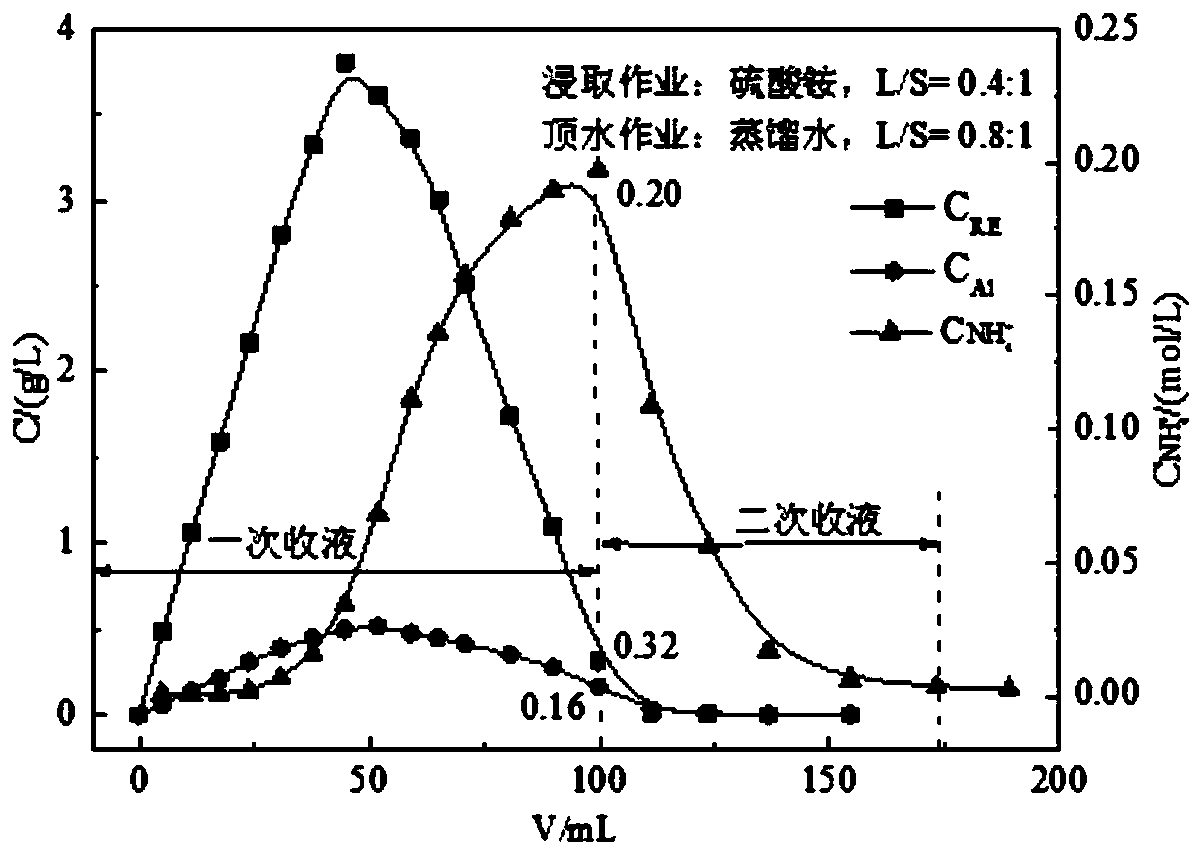

[0040] Weigh 250g of dried weathering crust elution-type rare earth ore sample, slowly and evenly put it into a glass column with a diameter of 45mm, spread 2 to 3 layers of filter paper on the surface of the ore layer, and then pass through a constant flow pump at a speed of 0.4mL / min With 100mL of 2% ammonium sulfate solution, the liquid-solid ratio of the volume (L) of the ammonium sulfate solution to the mass (kg) of the rare earth ore is 0.4:1 at this time, and the ammonium sulfate solution is sent to the top of the ore sample for leaching. After the ammonium sulfate solution is completely injected into the glass column, 200mL of distilled water is used for top water operation. At this time, the liquid-solid ratio of distilled water (L) to the mass of rare earth minerals (kg) is 0.8:1.

[0041] S2, collecting the rare earth leach solution twice

[0042] Use a beaker to collect the rare earth leaching sol...

Embodiment 2-6

[0050] The ore leaching method of a kind of weathering crust leaching type rare earth ore provided in Implementation 2-6 is basically the same as the leaching method of a kind of weathering crust leaching type rare earth ore provided in the embodiment, the difference is that the specific operating conditions change .

Embodiment 2

[0052] S1. Leaching weathering crust leaching type rare earth ore

[0053] The leaching agent is 3% ammonium sulfate, and the liquid-solid ratio is 1.2:1 during top water operation.

[0054] S2, collecting the rare earth leach solution twice

[0055] The rare earth leach solution collected for the first time had a rare earth concentration of 3.63g / L and an impurity aluminum concentration of 0.41g / L.

[0056] S3, impurity removal and precipitation steps

[0057] Add 5 mL of 5% ammonium bicarbonate solution during the impurity removal process, adjust the pH to 4.8, stir for 1.5 h, and let it stand for 4 h.

[0058] Add 10mL of 5% ammonium bicarbonate solution to the impurity-removed leaching solution, stir for 2 hours, and then let it stand and age for 6 hours. In the rare earth carbonate product, the rare earth purity reaches 97.34%, and the rare earth recovery rate is 98.12%.

[0059] Add ammonium sulfate solid to the supernatant to make the concentration of ammonium sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com