Preparation method and application of monodisperse superparamagnetic nano magnetic bead

A magnetic nanometer and superparamagnetic technology, which is applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve problems such as poor suspension stability, reduced magnetic responsiveness, and reduced magnetic content, and achieve low preparation costs. Simple preparation method, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 The preparation method of the monodisperse superparamagnetic nano-magnetic beads with high adsorption performance of the present invention

[0036] (1) Preparation of monodisperse superparamagnetic nano-magnetic beads

[0037] The invention adopts the improved solvothermal method, innovatively adds PEG in the reaction system to improve the dispersibility of the product, thereby synthesizing monodisperse nano-Fe 3 o 4 Particles, good dispersion performance, uniform particle size. The specific preparation method is as follows: 15mmolFeCl 3Dissolve in 300ml of ethylene glycol, then add 3.6g of NaAc and 10g of PEG 2000, shake and mix until the solid is completely dissolved, transfer the reaction liquid to a reaction kettle, and react at 200°C for 8 hours. After the reaction is completed, use a magnetic frame to magnetically separate and recover monodisperse nano-Fe 3 o 4 Particles were washed with water and ethanol several times to remove residual reaction...

Embodiment 2

[0051] Example 2: Suspension stability and magnetic responsiveness test of magnetic beads

[0052] Use TE solution to prepare the magnetic beads (number PC) of the present invention to a concentration of 10mg / ml, and after mixing thoroughly: ①Stand at room temperature, and record the time from the homogeneous system to the complete settlement of the magnetic beads. ② After fully mixing, place on the magnetic stand, and record the time required for the magnetic beads to be completely adsorbed to the side of the magnet and the solution to be completely clarified.

[0053] PC is the magnetic bead finally obtained through surface hydroxylation, amino and carboxylation modification treatment in the present invention, A is the magnetic bead obtained only through surface hydroxylation treatment, and B is the magnetic bead obtained through surface hydroxylation and amino modification treatment , C is carboxyl magnetic beads purchased from Beckman Company of the United States.

[0054...

Embodiment 3

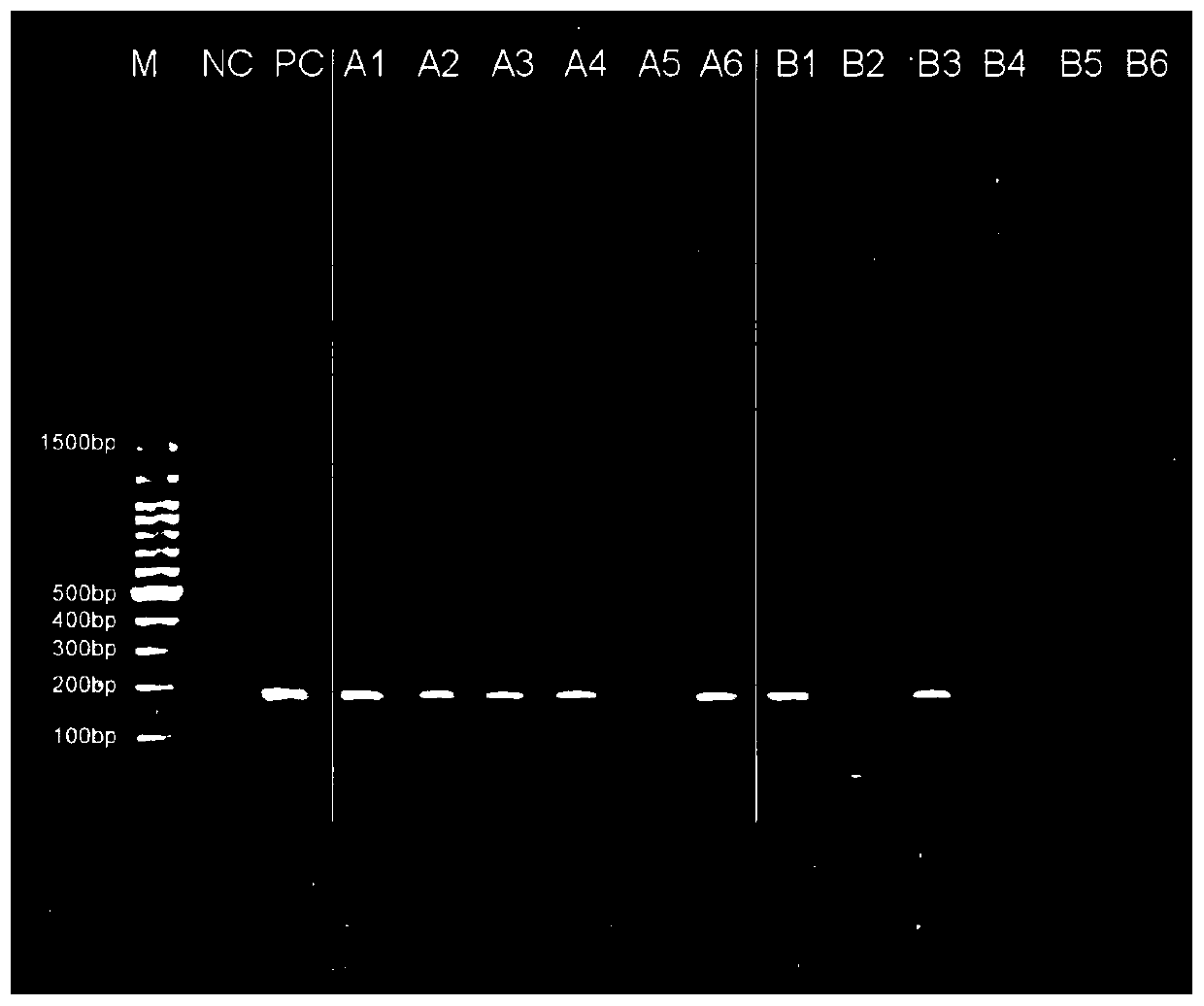

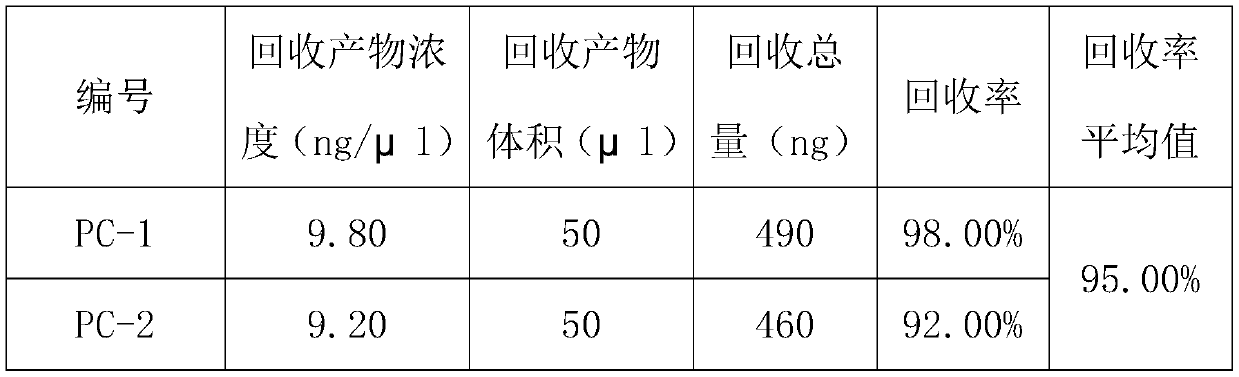

[0056] Embodiment 3: DNA recovery rate test-1

[0057] Disperse the magnetic beads in the PEG solution at a concentration of 1 mg / ml, use Marker (100bp-III DNA Ladder) as a test sample, and dilute its concentration to 10 ng / μl.

[0058] Take 50 μl of the diluted Marker (10ng / μl) in an EP tube, add 90 μl of magnetic beads (1mg / ml), and vortex for 5 minutes.

[0059] After brief centrifugation, place the EP tube on the magnetic stand. After the solution is clarified, discard the supernatant and wash the magnetic beads twice with 80% ethanol.

[0060] After drying the ethanol, add 50 μl TE solution, vortex for 3 minutes, place the centrifuge tube on the magnetic stand, and after the solution is completely clear, transfer the supernatant to a new EP tube to obtain the recovered product.

[0061] The concentration of the recovered product was measured, and then the recovery rate was calculated. The results are as follows (PC represents the magnetic beads of the present invention)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com