Delamanid quick-release preparation and preparation method thereof

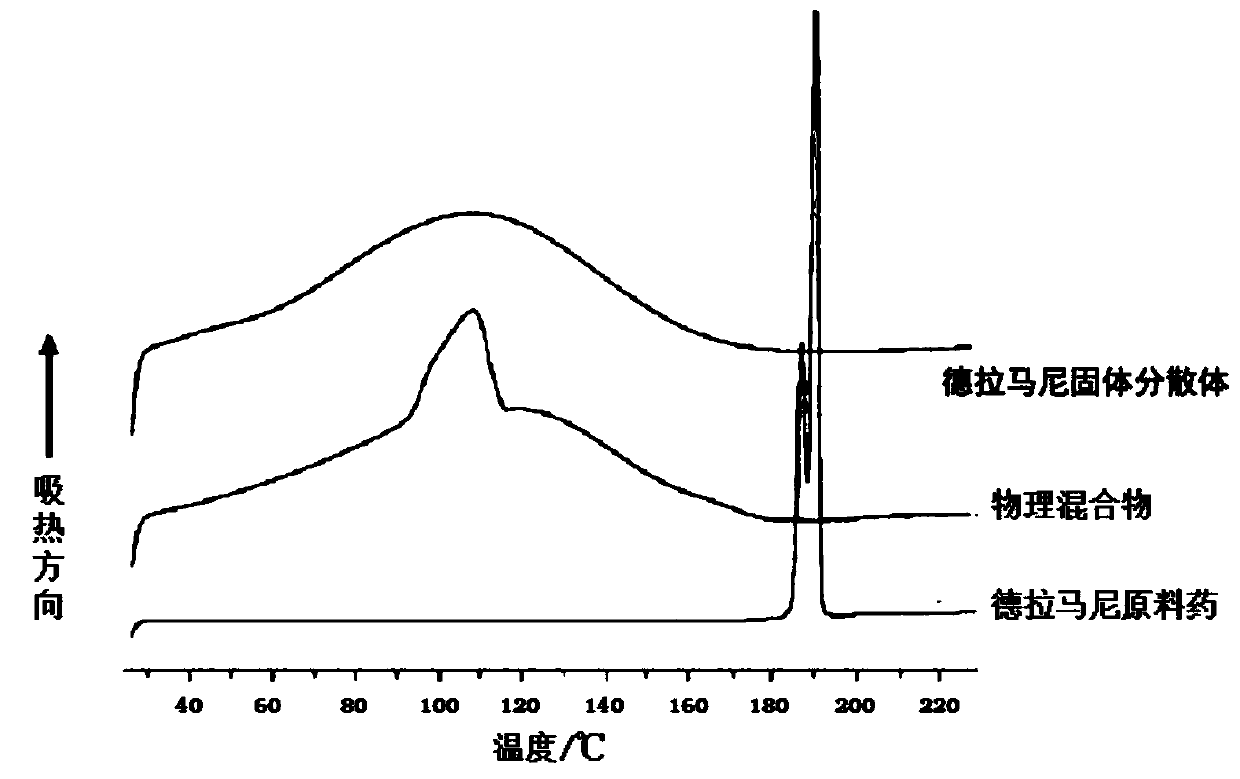

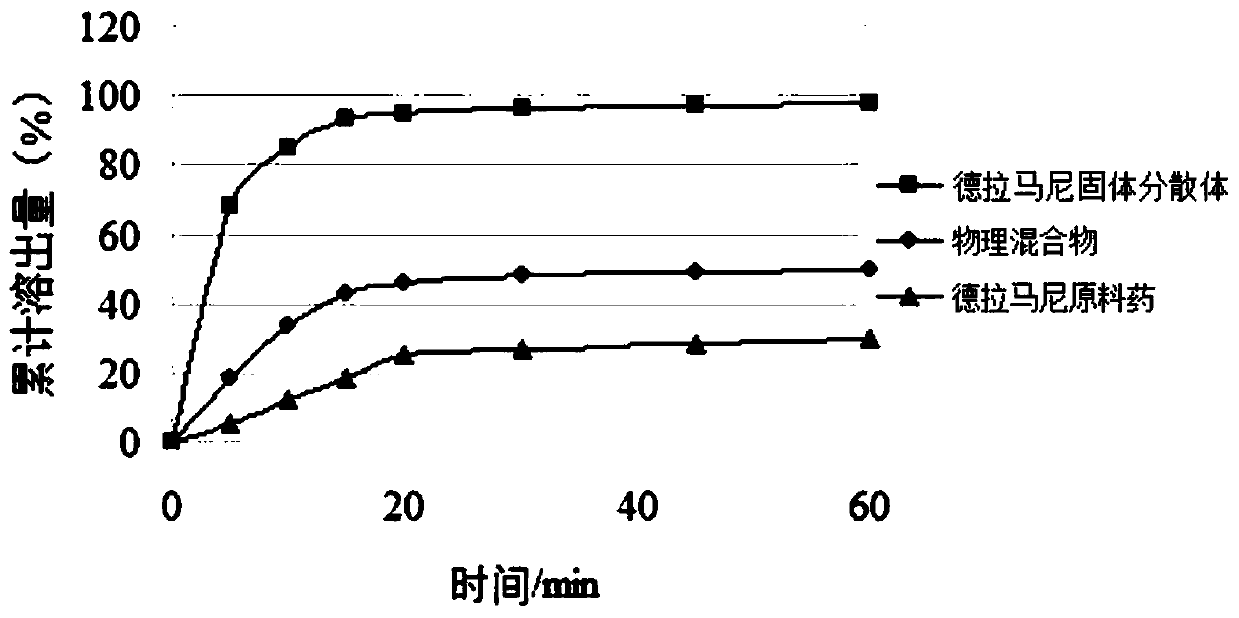

A technology for immediate-release preparations and lubricants, which is applied in the directions of pill delivery, pharmaceutical formulations, and medical preparations with inactive ingredients, etc., can solve problems such as poor in vitro dissolution of delamanid, and achieve improved in vitro and in vivo performance and low energy consumption. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

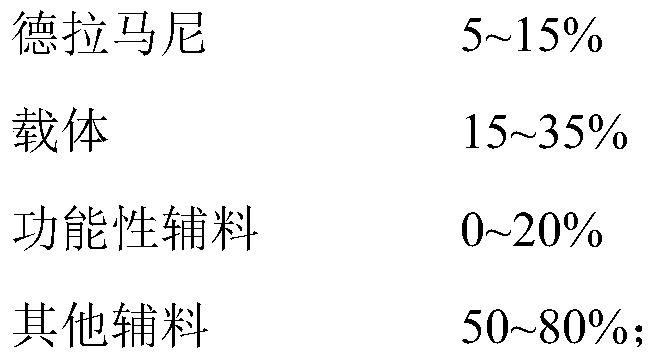

[0032] A delamanid immediate-release preparation made of the following components in mass percent:

[0033]

[0034] Preparation:

[0035] (1) After delamanid, xylitol and hypromellose phthalate are passed through an 80 mesh sieve respectively, they are mixed with a three-dimensional mixer to obtain a physical mixture;

[0036] (2) Preheat the hot-melt extruder for 30 minutes, set the hot-melt extrusion temperature to 175°C, and set the screw speed to 45r / min. After the temperature reaches the set temperature, add the physical mixture evenly into the hot-melt extruder In the stuffing hopper, it is melted by the screw of the hot-melt extruder, mixed, extruded, and strip-shaped solids are extruded;

[0037] (3) After the strip solid is cooled, it is pulverized into particles with a pulverizer, and the particles pass through a 40-mesh sieve to obtain a Dramani solid dispersion;

[0038] (4) Mix the Delamani solid dispersion with lactose, microcrystalline cellulose, croscarme...

Embodiment 2

[0043] A delamanid immediate-release preparation made of the following components in mass percent:

[0044]

[0045] Preparation:

[0046] (1) After delamanid, xylitol and hypromellose phthalate are passed through an 80 mesh sieve respectively, they are mixed with a three-dimensional mixer to obtain a physical mixture;

[0047] (2) Preheat the hot-melt extruder for 30 minutes, set the hot-melt extrusion temperature to 185°C, and set the screw speed to 50r / min. After the temperature reaches the set temperature, add the physical mixture evenly into the hot-melt extruder In the stuffing hopper, it is melted by the screw of the hot-melt extruder, mixed, extruded, and strip-shaped solids are extruded;

[0048] (3) After the strip solid is cooled, it is pulverized into particles with a pulverizer, and the particles pass through a 40-mesh sieve to obtain a Dramani solid dispersion;

[0049] (4) Mix the Delamani solid dispersion with lactose, microcrystalline cellulose, croscarme...

Embodiment 3

[0052] A delamanid immediate-release preparation made of the following components in mass percent:

[0053]

[0054]

[0055] Preparation:

[0056] (1) Pass through an 80-mesh sieve respectively after delamani, xylitol and hypromellose acetate phthalate are mixed with a three-dimensional mixer to obtain a physical mixture;

[0057](2) Preheat the hot-melt extruder for 30 minutes, set the hot-melt extrusion temperature to 175°C, and set the screw speed to 45r / min. After the temperature reaches the set temperature, add the physical mixture evenly into the hot-melt extruder In the stuffing hopper, it is melted by the screw of the hot-melt extruder, mixed, extruded, and strip-shaped solids are extruded;

[0058] (3) After the strip solid is cooled, it is pulverized into particles with a pulverizer, and the particles pass through a 40-mesh sieve to obtain a Dramani solid dispersion;

[0059] (4) Mix the Delamani solid dispersion with lactose, microcrystalline cellulose, cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com