3D printing gradient porous graphene oxide three-dimensional microorganism electrode and preparing method thereof

A microbial electrode, gradient porous technology, applied in battery electrodes, biochemical fuel cells, circuits, etc., can solve the problem of inability to accurately control the extrusion and stop time of printing filaments, the adhesion of filaments and the collapse of the overall structure, which is not conducive to the effective transmission of electrons To achieve the effect of promoting electron transfer process, facilitating attachment and growth, and optimizing microbial electrochemical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add Fe 3+ A cross-linked gradient porous graphene oxide three-dimensional microbial electrode, the preparation method comprising the following steps:

[0037] 1) Prepare graphene oxide dispersion liquid by Hummers method, then through 18000rmp, 30min high-speed centrifugation obtains 25mg / ml graphene oxide hydrogel. Add 0.2mol / L Fe to the graphene oxide hydrogel in proportion to 3.11wt% 3+ solution, through Fe 3+ The cross-linking effect with -COOH, -OH and other functional groups in graphene oxide molecules can further improve the mechanical strength of the hydrogel network and make modified graphene oxide hydrogel.

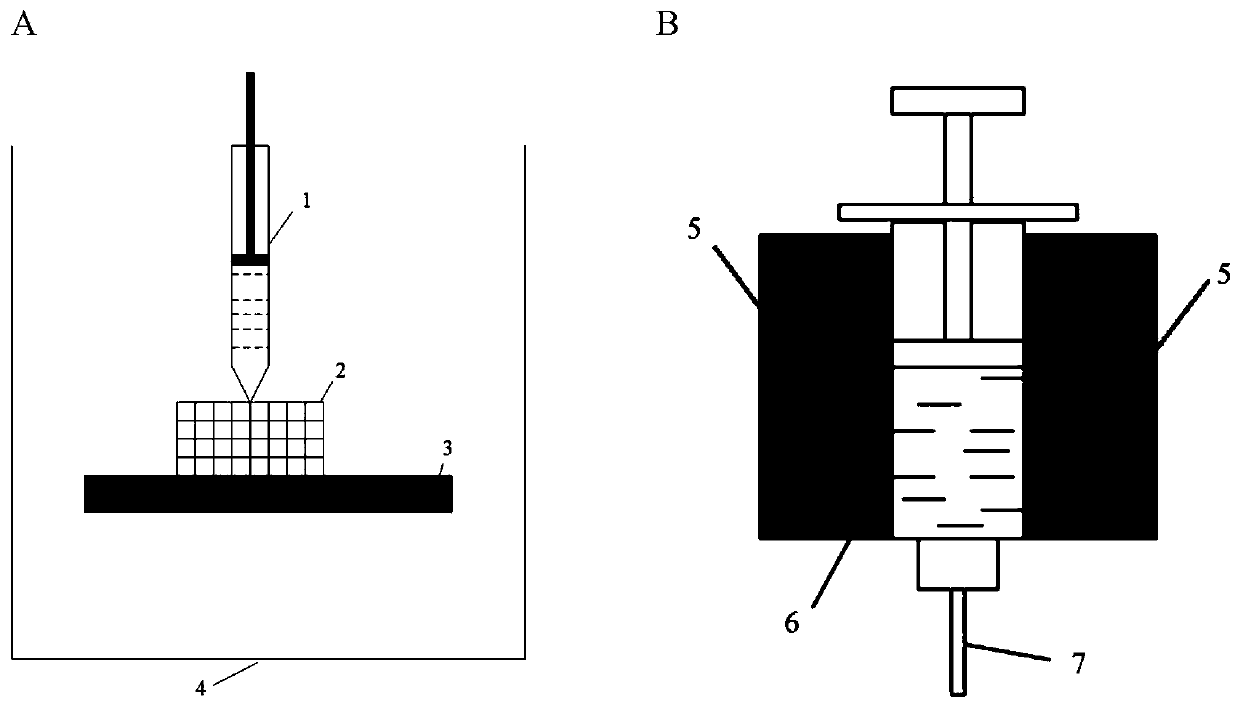

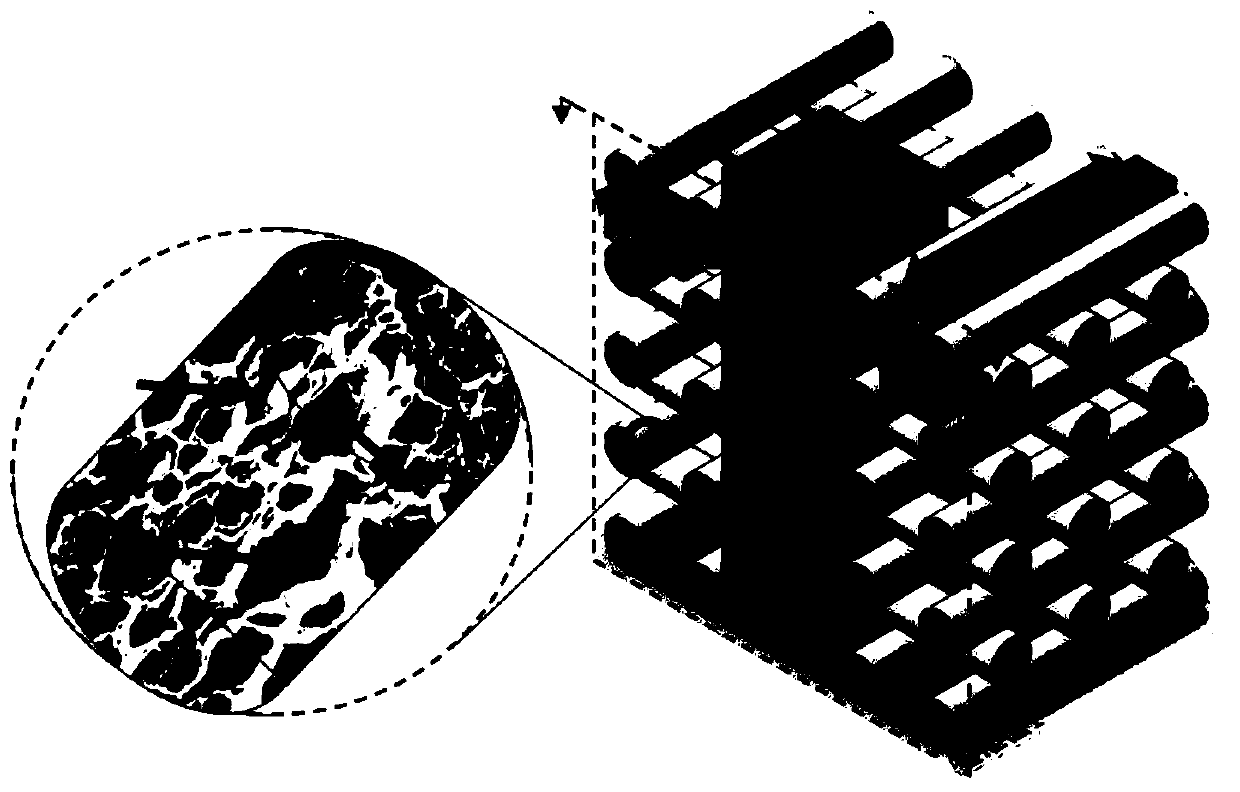

[0038] 2) 3D printing, made of gradient porous graphene oxide three-dimensional microbial electrode

[0039] Design a computer model of a new type of electrode based on the shape and position requirements of the microbial electrochemical system for the electrode, and layer through the software to generate a printing path to achieve a printing structure...

Embodiment 2

[0051] Add Ca 2+ A cross-linked gradient porous graphene oxide three-dimensional microbial electrode, the preparation method comprising the following steps:

[0052] 1) Prepare graphene oxide dispersion liquid by Hummers method, then through 18000rmp, 30min high-speed centrifugation obtains 25mg / ml graphene oxide hydrogel. Add 0.2mol / L Ca to the graphene oxide hydrogel in proportion to 3.11wt% 2+ solution, through Ca 2+ The cross-linking effect with -COOH, -OH and other functional groups in graphene oxide molecules can further improve the mechanical strength of the hydrogel network and make modified graphene oxide hydrogel.

[0053] 2) 3D printing, made of gradient porous graphene oxide three-dimensional microbial electrode

[0054] Design a computer model of a new type of electrode based on the shape and position requirements of the microbial electrochemical system for the electrode, and layer through the software to generate a printing path to achieve a printing structure...

Embodiment 3

[0066] Add Fe 3+ cross-linked, and use Fe 3 o 4A gradient porous graphene oxide three-dimensional microbial electrode in which nanoparticles enhance interfacial electron transfer, and the preparation method includes the following steps:

[0067] 1) Prepare graphene oxide dispersion liquid by Hummers method, then through 18000rmp, 30min high-speed centrifugation obtains 25mg / ml graphene oxide hydrogel. Add 0.2mol / L Fe to the graphene oxide hydrogel in proportion to 3.11wt% 3+ solution with 2.08mmol Fe 3 o 4 Nanoparticles, after being fully mixed, are made into modified 3D printing graphene oxide ink.

[0068] 2) 3D printing, made of gradient porous graphene oxide three-dimensional microbial electrode

[0069] Design a computer model of a new type of electrode based on the shape and position requirements of the microbial electrochemical system for the electrode, and layer through the software to generate a printing path to achieve a printing structure of 20×20×5mm and a wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com