Preparation method of modified graphene

A graphene and modification technology, applied in the field of graphene, can solve the problems of limited number of active reaction sites, insufficient number of branched chains, and inability to achieve graphene sheet monolayer dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

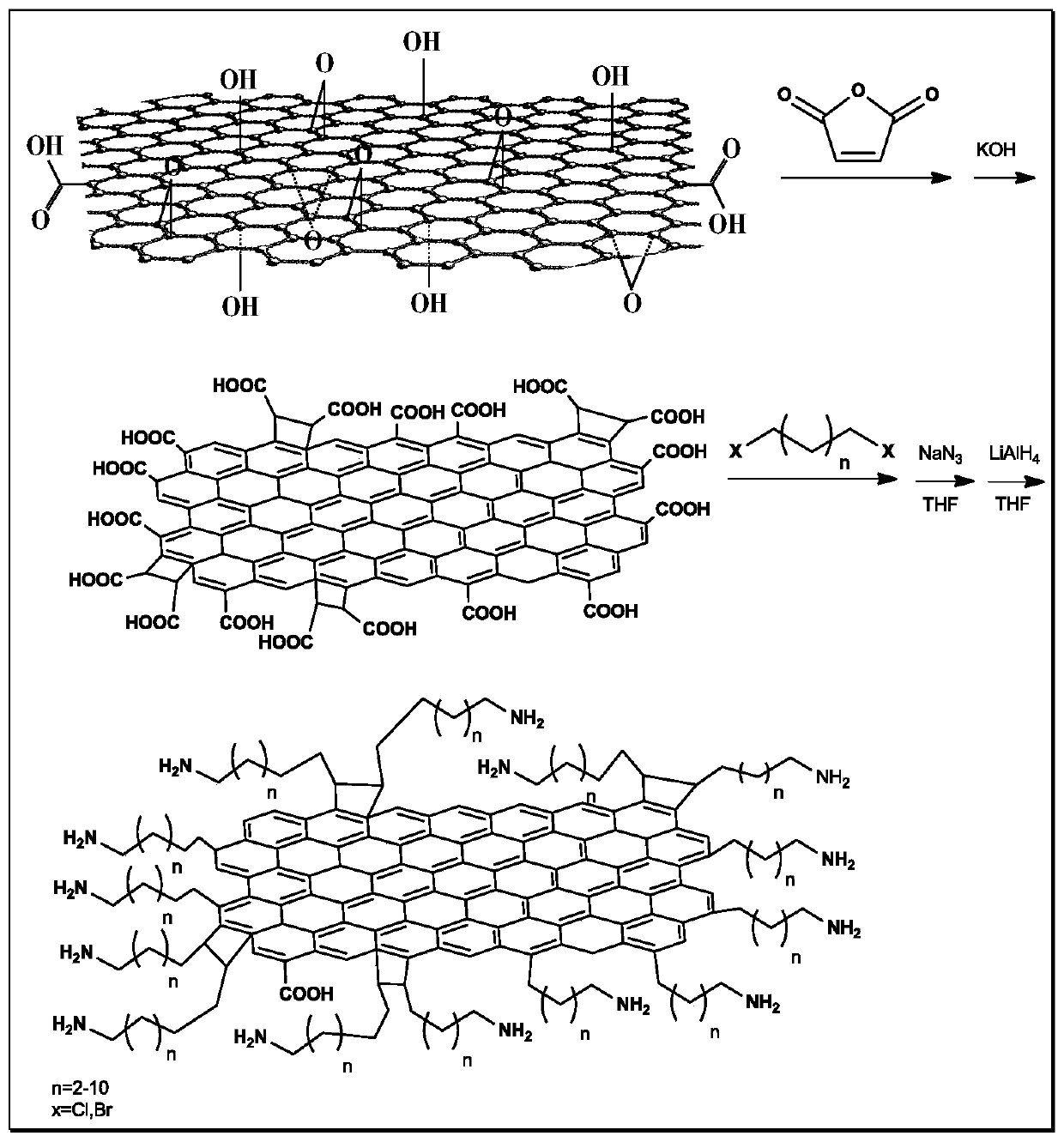

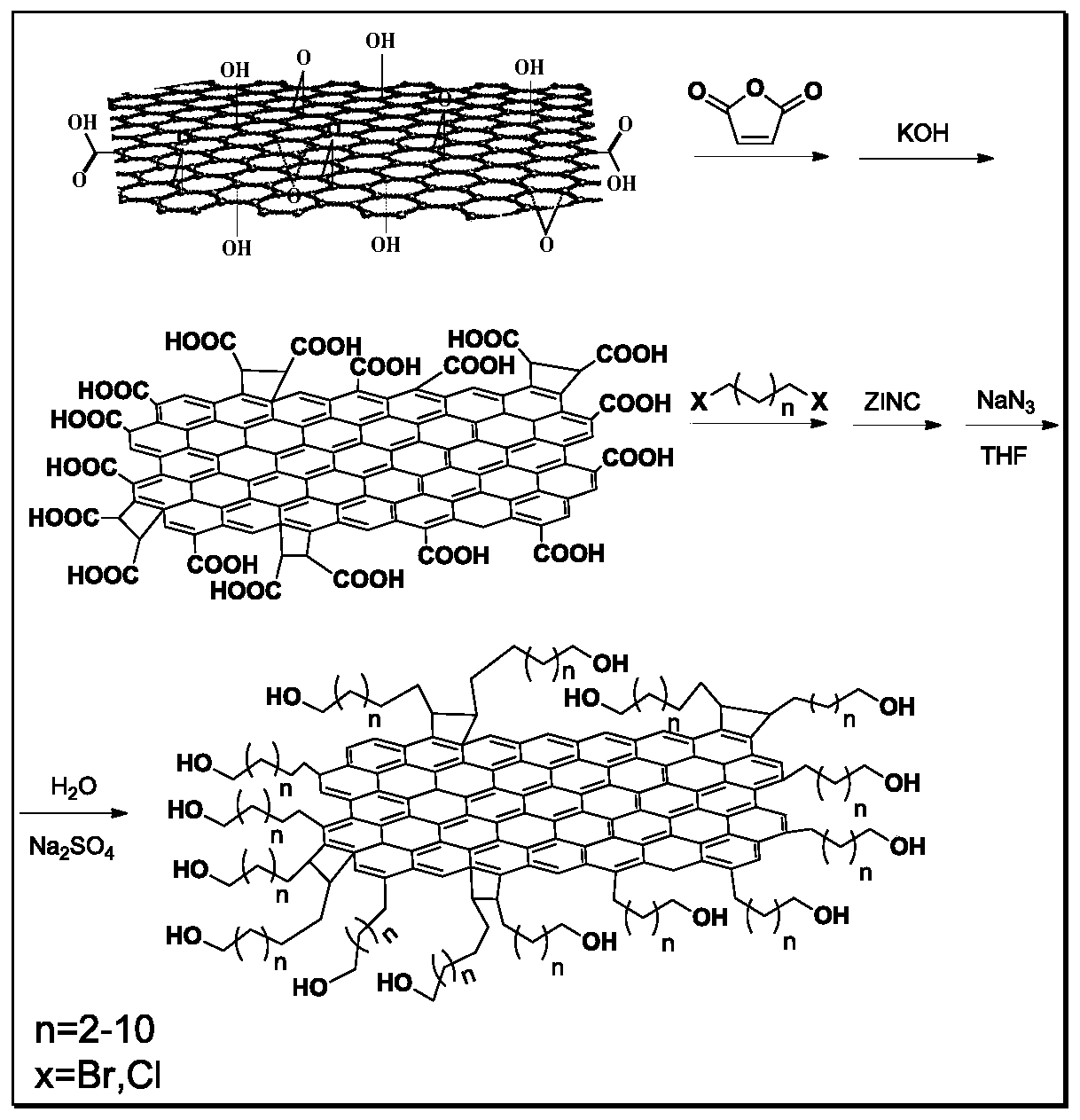

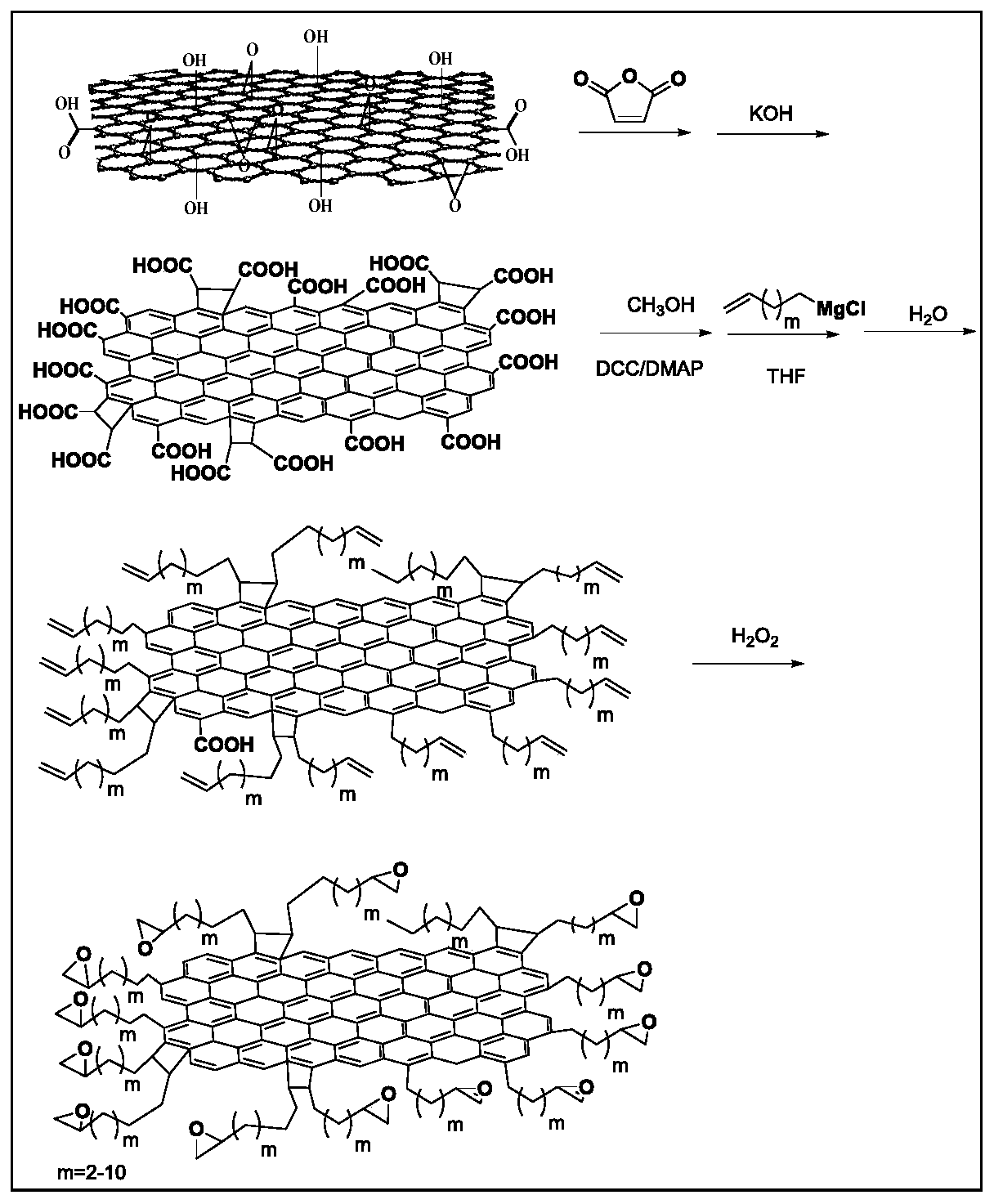

[0050] The invention provides a method for preparing modified graphene, comprising: S1) dispersing graphene oxide in tetrahydrofuran to obtain a graphene oxide colloidal solution; S2) mixing the graphene oxide colloidal solution with an acid anhydride compound, Irradiating to obtain modified graphene oxide; the acid anhydride compound includes a diformic anhydride structure or isatoic anhydride structure; S3) after hydrolyzing the modified graphene oxide, carboxyl-modified graphene is obtained.

[0051]The present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made. Wherein, the graphene oxide is preferably graphene oxide obtained by Hummers method oxidation, more preferably graphene oxide obtained by Hummers graphite oxide or graphene-based materials.

[0052] Disperse graphene oxide in tetrahydrofuran to obtain a graphene oxide colloidal solution; the dispersion method in the present invention is preferabl...

Embodiment 1

[0110] First, the graphite or graphene material is oxidized by the Hummers method to obtain graphene oxide. 0.2 g of graphene oxide was ultrasonically dispersed in 100 ml of tetrahydrofuran solution for 15 minutes, and a graphene oxide colloidal solution was obtained after ultrasonic dispersion.

[0111] Then add 0.4 g of maleic anhydride to the graphene oxide colloidal solution, and ultrasonically disperse for 15 minutes. The graphene oxide / maleic anhydride / THF mixture was irradiated in a Co-60 source with a radiation dose of 40 kGy and a dose rate of 25 Gy / min. The modified graphene oxide is obtained after the insoluble matter in the mixed solution after irradiation is suction-filtered, washed to neutrality and dried.

[0112] Weigh 0.2 g of modified graphene oxide, soak in 1 mmol / L KOH aqueous solution and 1 mmol / L hydrochloric acid solution for 5 minutes and 10 minutes respectively for hydrolysis. After the product was suction-filtered and washed with deionized water to ...

Embodiment 2

[0118] First, the graphite or graphene material is oxidized by the Hummers method to obtain graphene oxide. 0.2 g of graphene oxide was ultrasonically dispersed in 100 ml of tetrahydrofuran solution for 15 minutes, and a graphene oxide colloidal solution was obtained after ultrasonic dispersion.

[0119] Then add 0.4 g of maleic anhydride to the graphene oxide colloidal solution, and ultrasonically disperse for 15 minutes. The graphene oxide / maleic anhydride / THF mixture was irradiated in a Co-60 source with a radiation dose of 40 kGy and a dose rate of 25 Gy / min. The modified graphene oxide is obtained after the insoluble matter in the mixed solution after irradiation is suction-filtered, washed to neutrality and dried.

[0120] Weigh 0.2 g of modified graphene oxide, soak in 1 mmol / L KOH aqueous solution and 1 mmol / L hydrochloric acid solution for 5 minutes and 10 minutes respectively for hydrolysis. After the product was suction-filtered and washed with deionized water to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com