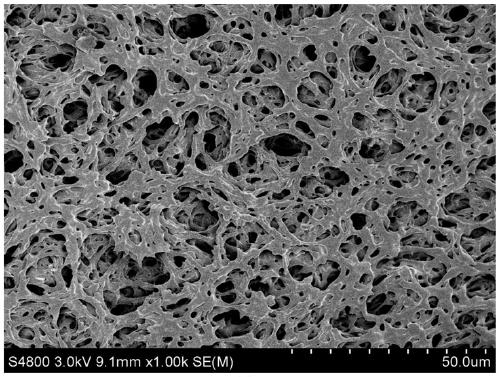

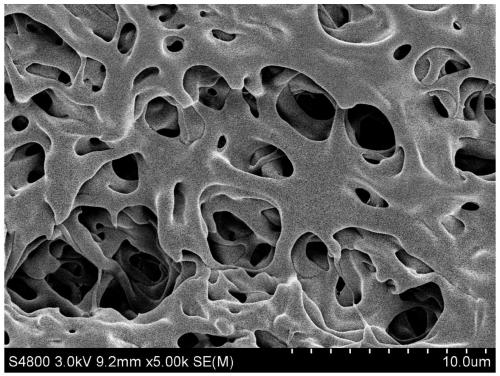

Biochar/polyvinyl formal porous composite filler, and preparation method and application thereof

A polyvinyl formal and composite filler technology, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of difficult film hanging, easy detachment of biofilm, and reduction of specific surface area. , to achieve the effect of favorable for mass transfer of pollutants and dissolved oxygen, uniform distribution of pore structure, and improvement of treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] a. Weigh 20g of polyvinyl alcohol particles into the reaction kettle, add 170g of distilled water, heat in a constant temperature water bath, set the temperature at 95°C and mechanically stir within the range of 300r / min for 1.5h until the polyvinyl alcohol particles are all Dissolved to obtain a clear aqueous solution of polyvinyl alcohol.

[0037] b. Cool the polyvinyl alcohol aqueous solution obtained in a to 45° C. and keep the temperature constant. Increase the mechanical stirring speed to 550r / min, add 1.5g of calcium carbonate solid powder, 0.5g of sodium lauryl sulfate, and 10g of biochar powder while stirring, and continue stirring for 10 minutes to fully dissolve the sodium lauryl sulfate, carbonic acid Calcium and biochar powder are uniformly dispersed in polyvinyl alcohol aqueous solution.

[0038] c. Keep the mechanical stirring speed at 550r / min, fully mix 25g of sulfuric acid solution and 20g of formaldehyde solution, then slowly add to the reaction kett...

Embodiment 2

[0043] a. Weigh 20g of polyvinyl alcohol particles into the reaction kettle, add 160g of distilled water, heat in a constant temperature water bath, set the temperature at 95°C, and mechanically stir for 1 hour at a speed of 300r / min until the polyvinyl alcohol particles are all Dissolved to obtain a clear aqueous solution of polyvinyl alcohol.

[0044] b. Cool the polyvinyl alcohol aqueous solution obtained in a to 40° C. and keep the temperature constant. Increase the mechanical stirring speed to 500r / min, add calcium carbonate solid powder 1g, sodium lauryl sulfate 1g, biochar powder 12g under stirring state, keep stirring for 10min to fully dissolve sodium lauryl sulfate, calcium carbonate and The biochar powder was uniformly dispersed in the polyvinyl alcohol aqueous solution.

[0045] c. Keep the mechanical stirring speed at 500r / min, fully mix 30g of sulfuric acid solution and 25g of formaldehyde solution, then slowly add to the reaction kettle, the volume of the foami...

Embodiment 3

[0050] a. Weigh 20g of polyvinyl alcohol particles into the reaction kettle, add 160g of distilled water, heat with a constant temperature water bath, set the temperature at 95°C, and mechanically stir for 2 hours at a speed of 300r / min until the polyvinyl alcohol particles are all Dissolved to obtain a clear aqueous solution of polyvinyl alcohol.

[0051] b. Cool the polyvinyl alcohol aqueous solution obtained in a to 50° C. and keep the temperature constant. Increase the mechanical stirring speed to 600r / min, add 2g of calcium carbonate solid powder, 0.5g of sodium lauryl sulfate, and 4g of biochar powder under stirring, and continue stirring for 10 minutes to fully dissolve the sodium lauryl sulfate and calcium carbonate and biochar powder are uniformly dispersed in polyvinyl alcohol aqueous solution.

[0052] c. Keep the mechanical stirring speed at 600r / min, fully mix 20g of sulfuric acid solution and 18g of formaldehyde solution, then slowly add to the reaction kettle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com