Jade glass ceramic full-body tile and production method thereof

A technology of glass-ceramic and glass-ceramic frit, applied in the field of building materials, can solve the problems of elimination, poor decorative effect and high production cost, achieve good economic and social benefits, high decorative art aesthetic value, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a jade glass-ceramic full-body brick, comprising:

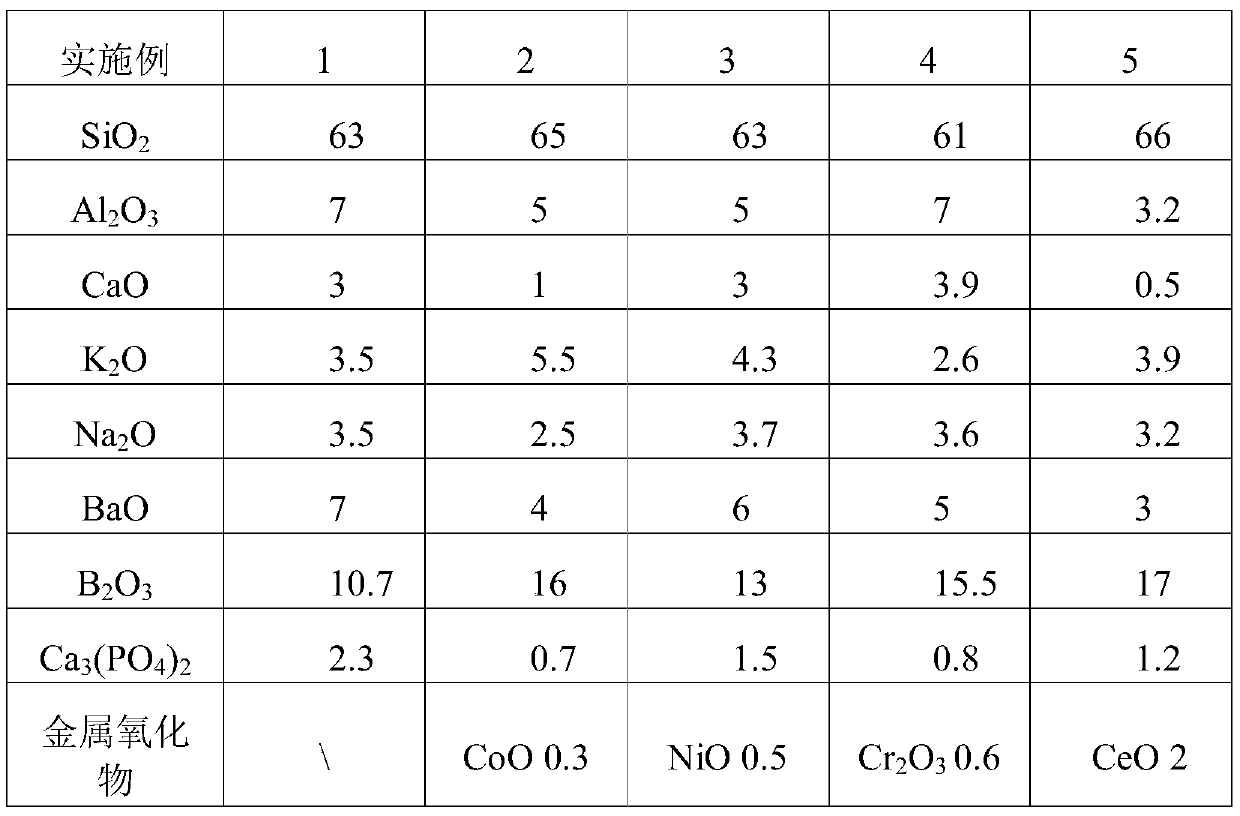

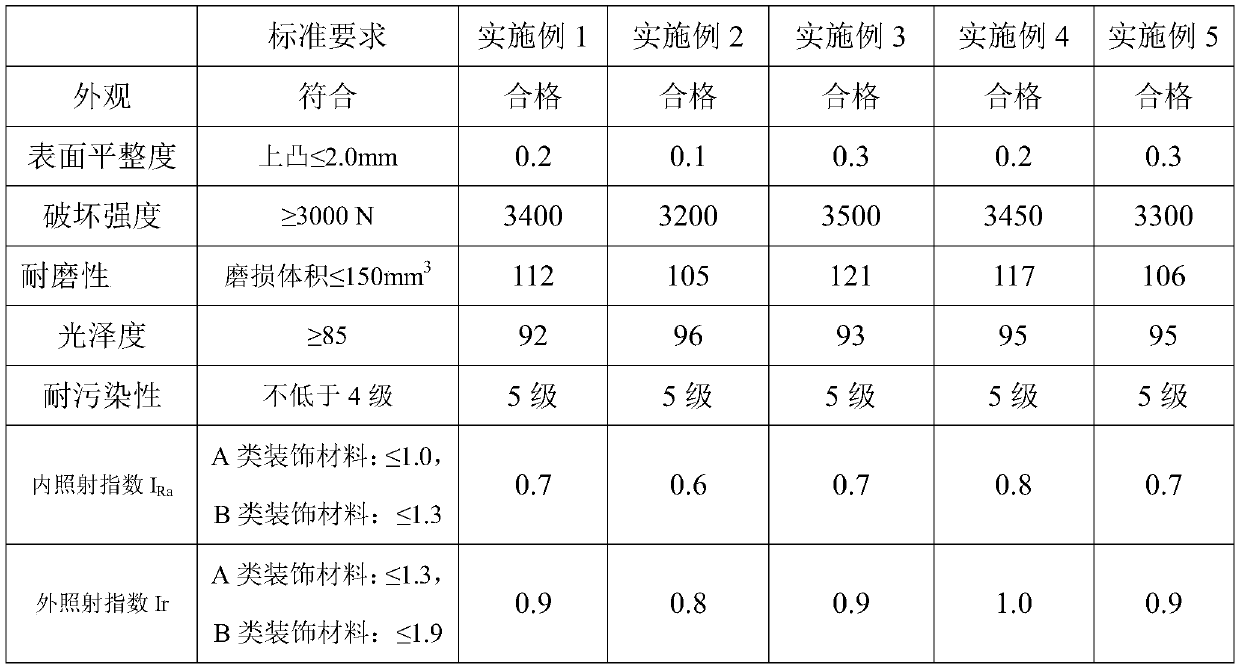

[0032] Preparation steps of jade glass-ceramic frit dry granules: ingredients, and then melting, water quenching, drying, crushing, sieving and sorting processes to obtain frit dry granules; frit dry granules include: The following components: SiO 2 60-70%, Al 2 o 3 2-8%, CaO 0.1-5%, K 2 O 2-7%, Na 2 O 2-8%, BaO 2-8%, B 2 o 3 10-18%, crystal nucleating agent 0.1-5%, coloring agent, the balance; the sum of the weight percentages of the above components is 100%;

[0033] Ceramic body preparation steps: batching, adding water and auxiliary materials, and then performing pulping, powder making, molding, drying and firing processes to obtain a ceramic body; the ceramic body includes the following components in terms of weight percentage: SiO 2 60-70%, Al 2 o 3 20-26%, CaO 0.1-2%, MgO 0.5-3%, K 2 O 1-4%, Na 2 O 1-4%, auxiliary material, 0-2%, the weight percentage sum of above-mentioned ...

Embodiment 1

[0044] A method for preparing a jade-quality glass-ceramic full-body brick, comprising the following steps:

[0045] Preparation of jade glass-ceramic frit dry particles: According to the conventional glass-ceramic frit preparation process, the following chemical raw materials are selected: potassium feldspar, albite feldspar, quartz, boric acid, barium carbonate, soda ash, potassium carbonate and calcium phosphate , through batching, melting at a temperature of 1480 ° C, and then sequentially performing water quenching, drying, crushing, sieving and sorting processes, to obtain frit dry particles including the following components in terms of weight percentage: SiO 2 63%, Al 2 o 3 7%, CaO 3%, K 2 O 3.5%, Na 2 O 3.5%, BaO 7%, B 2 o 3 10.7%, Ca 3 (PO 4 ) 2 2.3%; the particle size of fritted dry granules is 50-200 mesh, which is white fritted dry granules;

[0046] Preparation of ceramic tiles: According to the preparation method of ordinary ceramic tiles, the cerami...

Embodiment 2

[0049] The difference between embodiment 2 and embodiment 1 is:

[0050] In the preparation step of jade quality glass-ceramic frit dry grain: the component distribution ratio of frit dry grain is different (see Table 1 for details), and the color of frit dry grain is blue; After batching, the melting temperature is 1450°C;

[0051] In the preparation steps of the ceramic brick adobe: the temperature of the roller kiln is set to 1230°C;

[0052] In the preparation steps of jade-quality glass-ceramic full-body bricks: the thickness of high-temperature tissue paper is 1mm, and the high-temperature resistance is 1200°C; the amount of cloth of imitation jade frit dry particles on high-temperature tissue paper is 30Kg / m 2 ;The maximum firing temperature in the roller kiln is 1150°C, and the firing cycle is 60 minutes;

[0053] Others are identical with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com