Preparation method of original-ecology self-heat-insulation and decoration integrated wall material

A wall material and self-insulation technology, which is applied in the field of building exterior wall insulation and energy saving, decorative wall materials, and can solve problems such as rainwater leakage, poor block integrity, and casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] 4. Preparation process of wall materials

[0052] 1) According to the difference in thermal conductivity and other physical properties, take different proportions of raw materials.

[0053] 2) Pour the loess-MES modified expanded raw soil and ceramsite (clay ceramsite, shale ceramsite, fly ash ceramsite), fly ash, and straw (fiber) into the container according to the formula ratio and stir well until Mix well to form semi-finished material A.

[0054] 3) Mix graphite slag with airgel and cement, and stir evenly to form semi-finished material B.

[0055] 4) Pour the waste EPS, semi-finished material B, quicklime and water into the container and stir until they are evenly mixed. No heating is required during stirring. The temperature of the mixing system is controlled by the added quicklime and water at 50°C to 70°C. Stir After being uniform, a semi-finished material C is formed.

[0056] 5) When the temperature of the semi-finished material C is kept above 50°C, pour ...

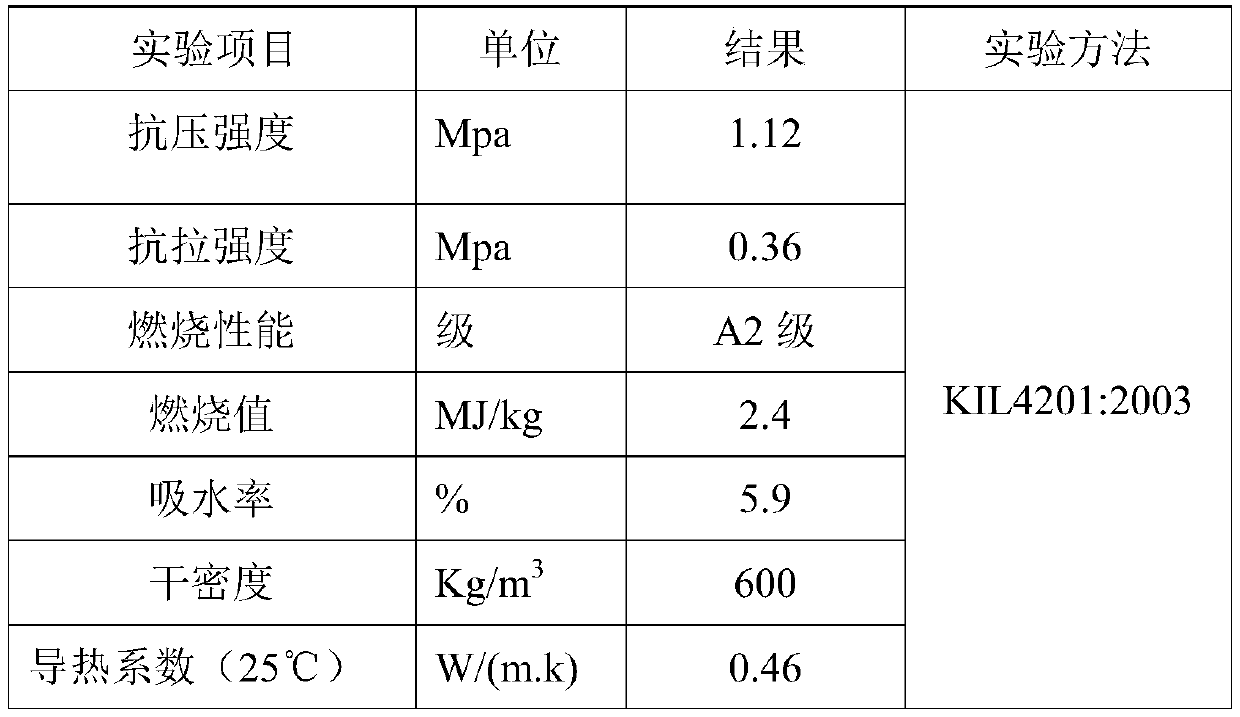

example 1

[0059] In terms of mass fraction, 32% loess-MES modified expanded raw soil, 8% clay ceramsite, 9% fly ash ceramsite, 8% straw (fiber) and 7% fly ash were poured into the container and stirred evenly. A semi-finished material A is formed.

[0060] Mix 3% graphite slag with 5% airgel and 3% cement, and stir evenly to form semi-finished material B.

[0061] Pour 7% waste EPS, semi-finished material B, 8% quicklime, and water into a container and stir and mix evenly. The temperature should be 50°C to 70°C during stirring, and semi-finished material C is formed after stirring evenly.

[0062] When the temperature of the semi-finished material C is kept above 50°C, pour the semi-finished material A into the semi-finished material C, stir and mix evenly, and when the temperature of the mixture is 50°C, add the prefabricated 50°C glutinous rice juice (10%) with water mist Spray into the mixture, stir evenly, heat up to 70°C, pour into the prefabricated mold, vacuumize, gradually pres...

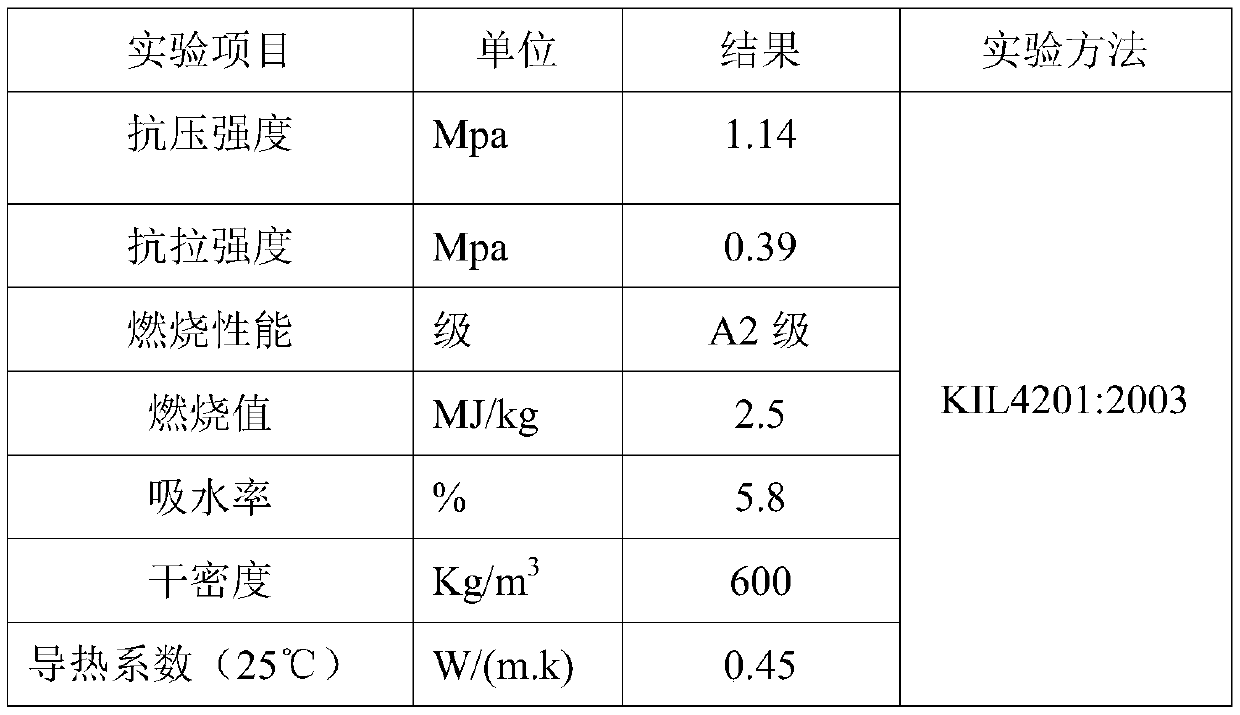

example 2

[0067] In terms of mass fraction, 28% loess-MES modified expanded soil, 6% clay ceramsite, 10% fly ash ceramsite, 12% shale ceramsite, 8% straw (fiber) and 7% fly ash Pour into a container and stir to mix evenly to form a semi-finished material A.

[0068] Mix 2% graphite slag, 4% airgel and 2% cement, and stir evenly to form semi-finished material B.

[0069] Pour 7% waste EPS, semi-finished material B, 5% quicklime, and water into a container and stir and mix evenly. The temperature should be 50°C to 70°C during stirring, and semi-finished material C is formed after stirring evenly.

[0070] When the temperature of the semi-finished material C is kept above 50°C, pour the semi-finished material A into the semi-finished material C, stir and mix evenly, and when the temperature of the mixture is 50°C, add the prefabricated 50°C glutinous rice juice (9%) with water mist Spray into the mixture, stir evenly, heat up to 70°C, pour into the prefabricated mold, vacuumize, gradually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com