A thermosensitive polymer and its synthesis method and thermosensitive injectable hydrogel

A synthesis method and polymer technology, applied in prosthesis, medical science and other directions, can solve the problems of unstable gel mechanical properties, low cross-linking point strength, limited application scope, etc., and achieve good biocompatibility and easy preparation. , The effect of avoiding the trouble of surgical removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

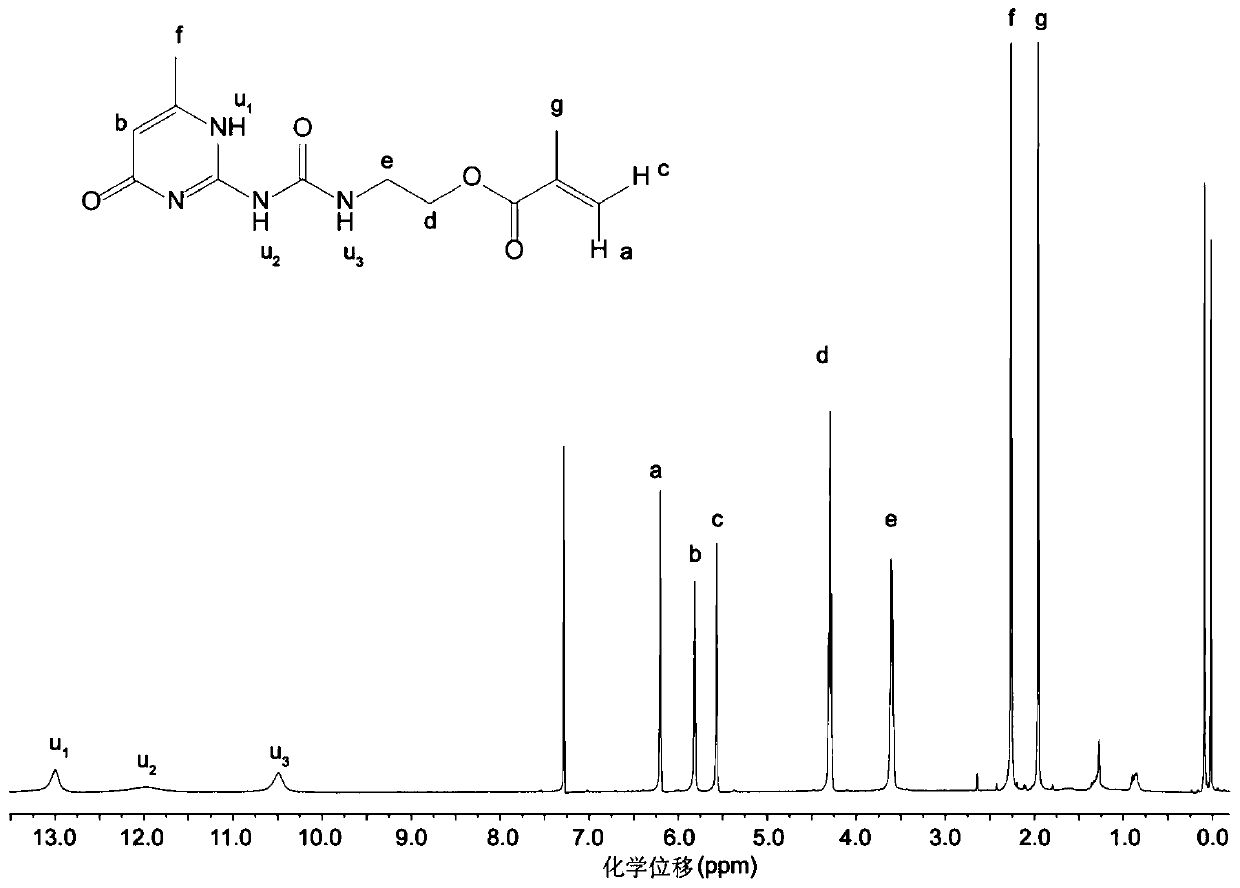

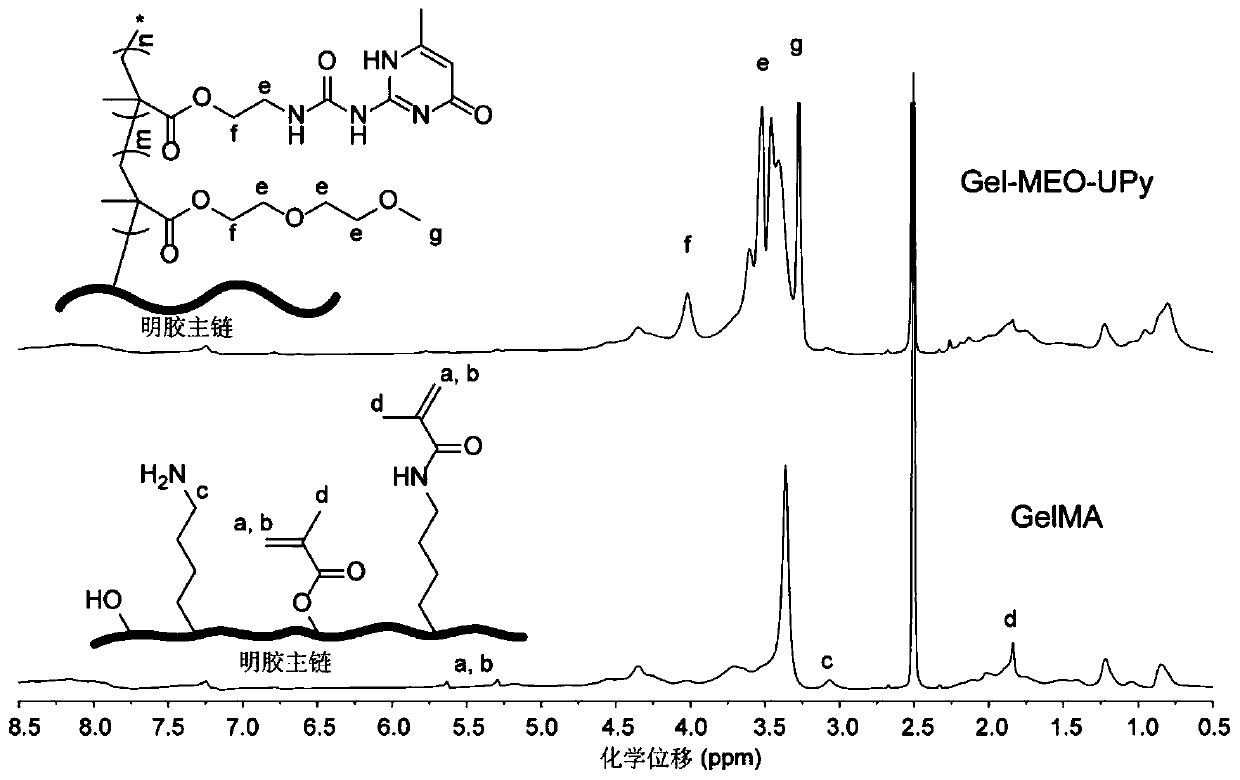

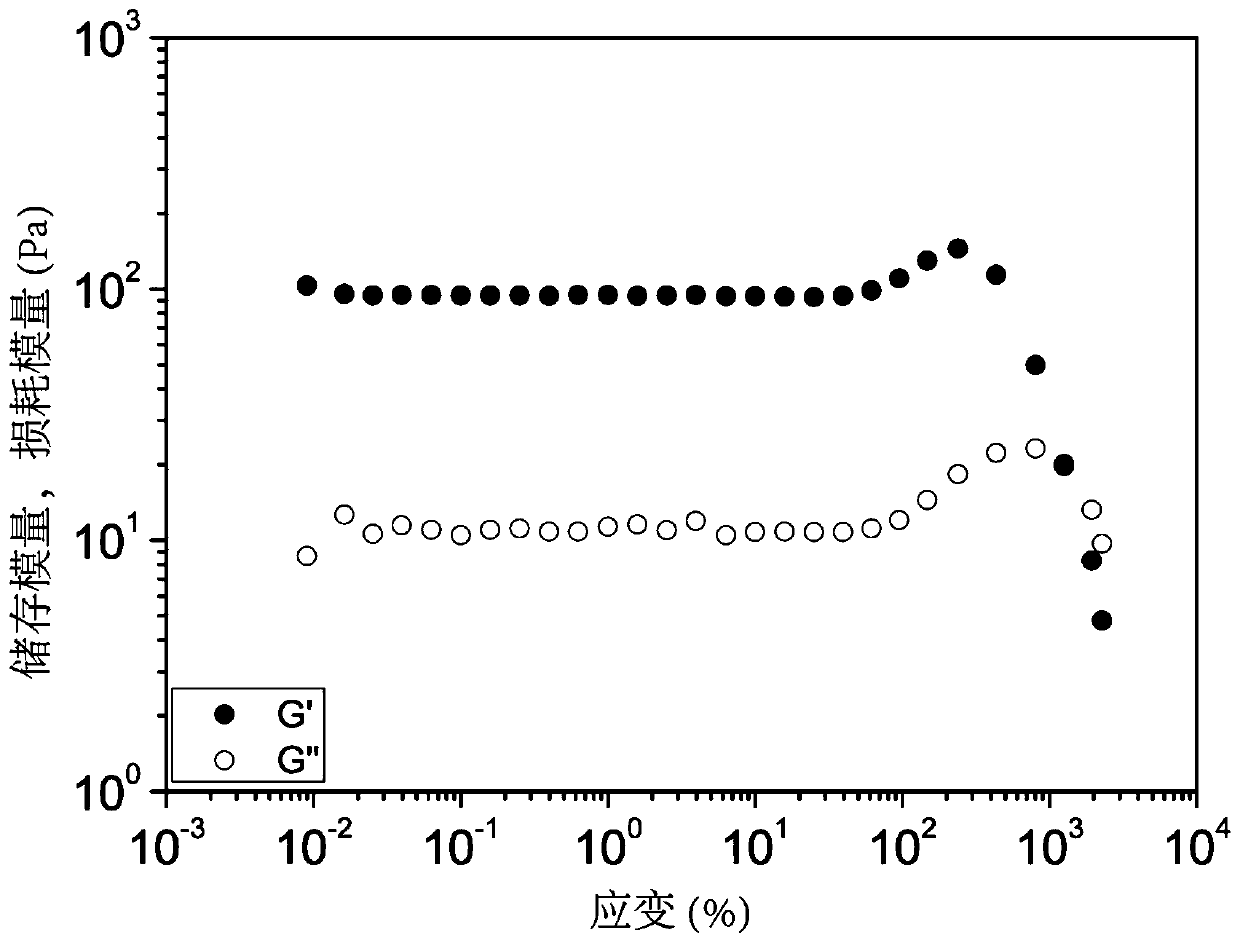

[0046] 1. Synthesis of Thermosensitive Polymers

[0047] (1) Synthesis of GelMA (methacrylic acylated gelatin) using gelatin and methacrylic acid anhydride:

[0048] ①Put 6g of solid gelatin and 60ml of 1×PBS into a 250ml round-bottomed flask with a 4cm double-tip PTFE magnetic rotor, seal the container, stir at a constant speed of 300rpm, and dissolve it in a water bath at 40°C for 1 hour until the contents of the container are pale. yellow clear liquid;

[0049] ②Heating step ①The gelatin solution obtained in ① was brought to 50°C, kept stirring at 300rpm, and then slowly injected and dropped 12ml of methacrylic anhydride therein at a rate of 0.2ml / min;

[0050] ③ After the dropwise addition, fully react for 4 hours in a 50°C water bath with a stirring rate of 300rpm;

[0051] ④ Stop the reaction, dissolve the product, dilute the reaction system with 10 times the volume with 1×PBS, and then dissolve it in a water bath at 40°C for 1 hour;

[0052] ⑤Purify the product, 5 li...

Embodiment 2

[0083] 1. Synthesis of Thermosensitive Polymers

[0084] (1) Synthesis of GelMA (methacrylic acylated gelatin) using gelatin and methacrylic acid anhydride

[0085] ①Put 10g of solid gelatin and 100ml of 0.3M (0.09M Na 2 CO 3 , 0.21M NaHCO 3 )Na 2 CO 3 -NaHCO 3 Sodium bicarbonate aqueous solution, in a closed container, stirred at a constant speed of 300rpm, dissolved in a water bath at 40°C for 1 hour until the substance in the container is a light yellow clear liquid, and the pH value is adjusted to 9.0 with 5M NaOH aqueous solution;

[0086] ②Heating step ①The gelatin solution obtained in ① was brought to 50°C, kept stirring at 300rpm, and then slowly injected and dropped 1ml of methacrylic acid anhydride therein at a rate of 0.2ml / min;

[0087] ③ After the dropwise addition, fully react for 2 hours in a 50°C water bath with a stirring rate of 300rpm;

[0088] ④ Stop the reaction, dissolve the product, adjust the pH to 7.4 with 5M HCl aqueous solution, and then disso...

Embodiment 3

[0105] 1. Synthesis of Thermosensitive Polymers

[0106] (1) Synthesis of GelMA from gelatin and methacrylic acid anhydride

[0107] ①Put 10g of solid gelatin and 100ml of 0.2M (0.03M Na 2 CO 3 , 0.17M NaHCO 3 )Na 2 CO 3 -NaHCO 3 Sodium bicarbonate aqueous solution, in a closed container, stirred at a constant speed of 300rpm, dissolved in a water bath at 40°C for 1 hour until the substance in the container is a light yellow clear liquid, and the pH value is adjusted to 9.0 with 5M NaOH aqueous solution;

[0108] ②Heating step (1) ①The gelatin solution obtained is brought to 50°C, kept stirring at 300rpm, and then slowly injects 1ml of methacrylic anhydride therein dropwise, with a dropping rate of 0.2ml / min;

[0109] ③After the dropwise addition, fully react for 2 hours in a water bath at 50°C and a stirring rate of 300rpm (1)②The obtained system;

[0110] ④ Stop the reaction, dissolve the product, adjust the pH to 7.4 with 6M HCl aqueous solution, and then dissolve it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com