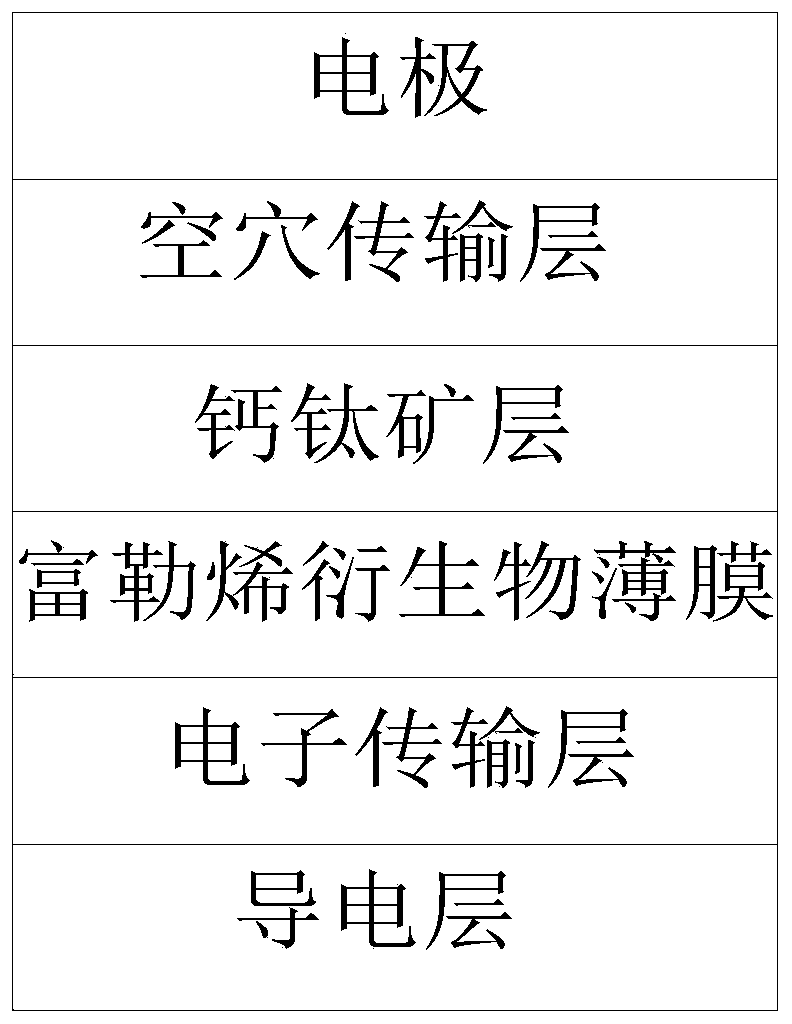

Application of phenol-substituted fullerene derivative in perovskite solar cell, perovskite solar cell and preparation method of perovskite solar cell

A technology for fullerene derivatives and solar cells, applied in the field of solar cells, can solve the problems of high cost, increased cost of solar cells, difficulty in separation and purification, etc., and achieves the effects of improving efficiency, improving electron transport performance, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] SnO 2 Preparation of the solution: Weigh 22.6 mg of tin chloride dihydrate (SnCl 2 2H 2 O), it was dissolved in absolute ethanol, stirred for 2h to obtain a concentration of 0.1M SnO 2 spare.

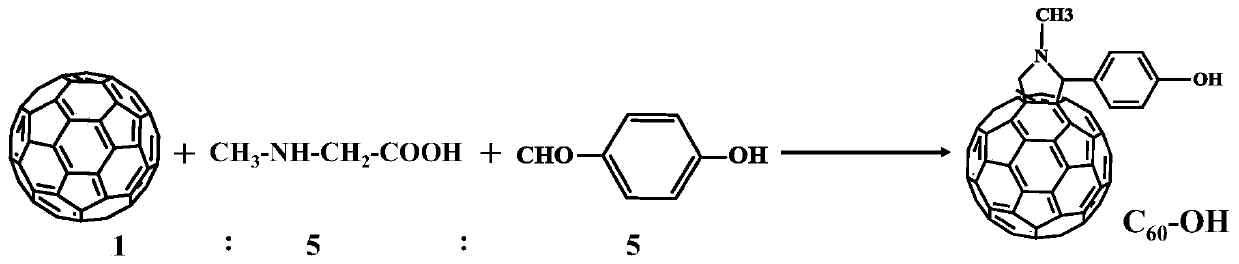

[0042] Preparation of fullerene derivative solution: Weigh different masses of (phenol-substituted fullerene derivatives), which are dissolved in ultra-dry chlorobenzene to prepare fullerene solutions with different concentrations, and the concentration range of the solution is 0.25-1.5mg / mL.

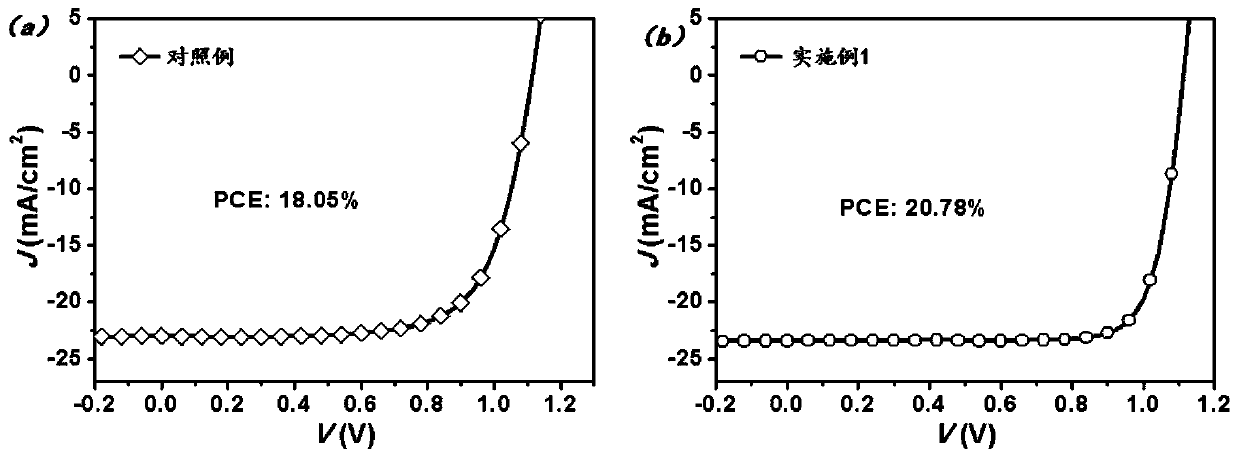

Embodiment 1

[0044] S1, SnO 2 Film preparation:

[0045] Filter the above SnO with a 0.45 μm Teflon filter head 2 solution, drop the filtered solution on the UVO-treated ITO substrate, and spin-coat at 2000 rpm, at a rate of 45 seconds, to form a thin film. Place the spin-coated ITO substrate on a titanium heating plate for heating at 150°C for half an hour, then at 180°C for one hour, cool to room temperature, and move it to a nitrogen glove box for later use.

[0046] S2, preparation of fullerene derivative film:

[0047] After the preparation of the tin oxide thin film of the electron transport layer was completed, a fullerene derivative solution with a concentration of 0.75 mg / mL was spin-coated on the tin oxide layer at a rotation speed of 1500 rpm for 60 seconds to obtain a fullerene derivative thin film.

[0048] S3, preparation of perovskite layer:

[0049] Preparation of perovskite precursor solution: Weigh formamidine hydriodide (FAI), methyl ammonium chloride (MACl) and meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com