Acetylene hydrochlorination catalyst based on porous tube wall hollow foam material and preparation method and application of acetylene hydrochlorination catalyst

A technology for acetylene hydrochlorination and foam materials, which is applied in the field of acetylene hydrochlorination reaction catalysts and preparations, and can solve the problems that the mass transfer and heat transfer processes cannot be finely regulated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

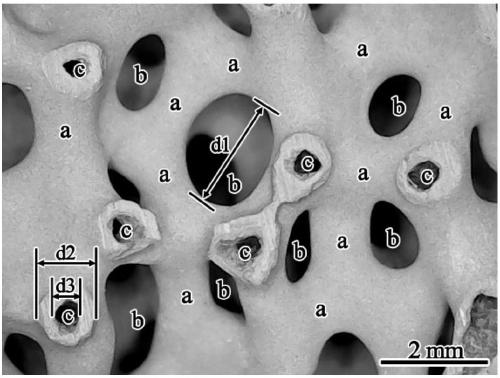

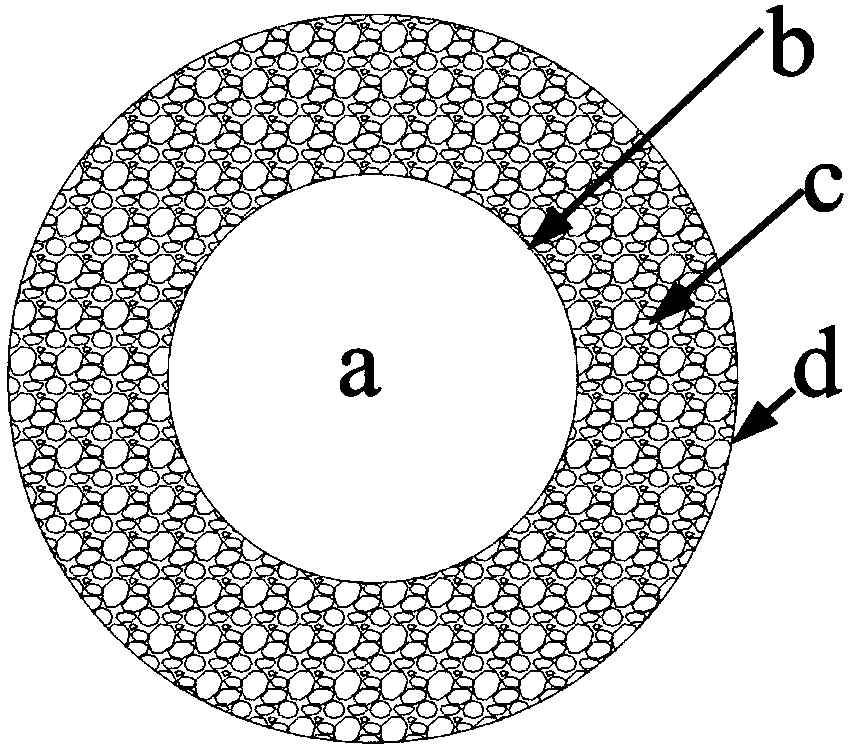

[0067] The hollow foam activated carbon material with porous structure microchannel tube wall is used as the carrier, the average size of the macroscopic three-dimensional interconnected openings is 3mm, the average size of the outer diameter of the hollow microchannel is 1mm, the average size of the inner diameter is 500μm, and the pores contained in the tube wall body The average pore size is 1 μm, and the porosity is 10%. The hollow foam activated carbon material is impregnated in the chloroauric acid solution, and after drying, the acetylene hydrogen based on the porous wall hollow foam material is uniformly loaded with the gold trichloride catalytic active component on the hollow microchannel pipe wall body with a porous structure. Chlorination reaction catalyst, wherein the gold content is 0.001wt%-1wt%. The catalyst is applied to the acetylene hydrochlorination reaction, and the mixed gas of acetylene and hydrogen chloride is simultaneously introduced into the hollow mi...

Embodiment 2

[0069] The hollow foam material with porous structure microchannel wall is used as the carrier, and the average size of the macroscopic three-dimensional interconnected openings is 3mm, the average size of the outer diameter of the hollow microchannel is 1mm, and the average size of the inner diameter is 1mm. The size is 500 μm, the average pore diameter of the pores contained in the tube wall body is 1 μm, and the porosity is 10%. The hollow foam (activated carbon-molecular sieve) material is impregnated in the chloroauric acid solution, and after drying, it is made into a hollow foam based on a porous tube wall that uniformly loads gold trichloride catalytically active components on the hollow microchannel tube wall body with a porous structure. The material is an acetylene hydrochlorination reaction catalyst, wherein the gold content is 0.001wt%-1wt%. The catalyst is applied to the acetylene hydrochlorination reaction, and the mixed gas of acetylene and hydrogen chloride is...

Embodiment 3

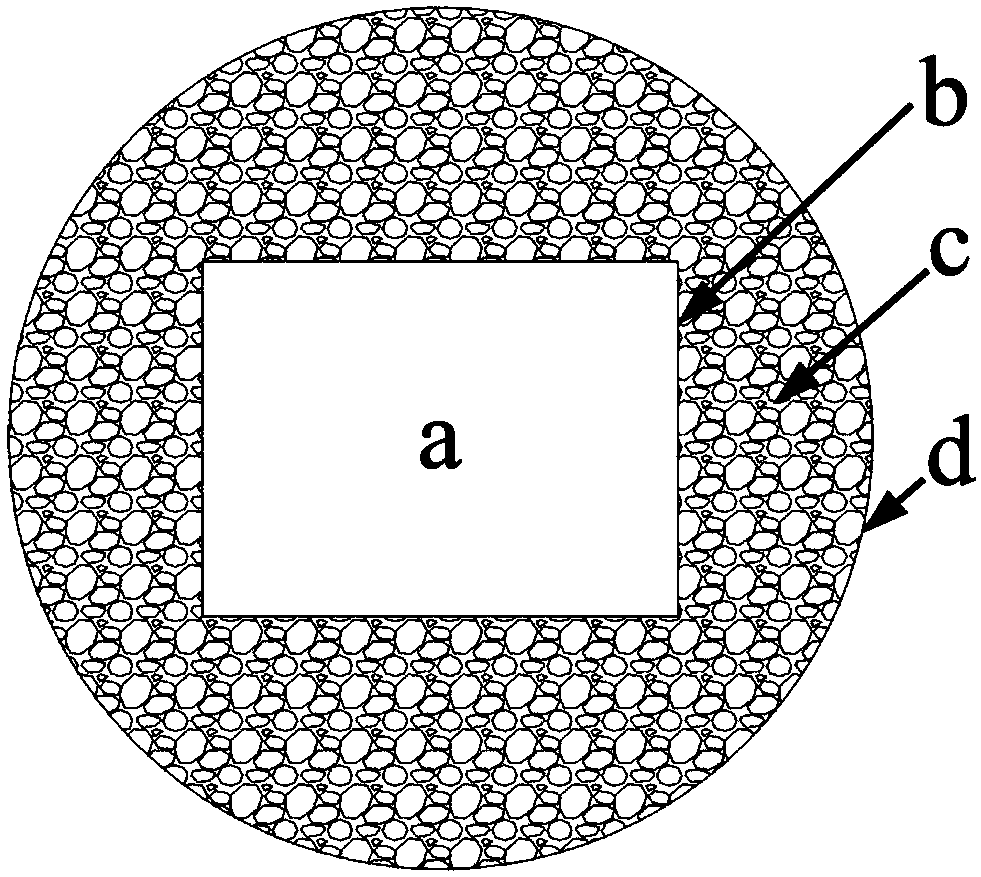

[0071]The hollow foamed silicon nitride material with a porous structure microchannel wall is used as the carrier, the average size of the macroscopic three-dimensional interconnected openings is 4mm, the average size of the outer diameter of the hollow microchannel is 1.5mm, and the transverse section of the cavity in the hollow microchannel The surface is a rectangle of 200 μm×300 μm, the average pore diameter of the pores contained in the tube wall body is 1 μm, and the porosity is 20%. The operation of "dipping slurry-removing excess slurry-semi-drying" is carried out by circulation to load the second carrier coating on the outside of the hollow microchannel tube wall, the composition is 90wt% activated carbon + 10wt% graphene, and the coating thickness is 80 μm. Then the sample is impregnated in the chloroauric acid solution, and after drying, it is made into a hollow microchannel wall with a porous structure. A gold trichloride catalytic active coating is loaded on the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com