Self-lubricating material and preparation method thereof

A technology of self-lubricating materials and sliding layers, which is applied in the field of materials, can solve the problems of increasing process complexity and production costs, and does not show the effective influence of the bonding strength of the sliding layer and the supporting layer, so as to achieve excellent peel strength and reduce material failure. Possibility, effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

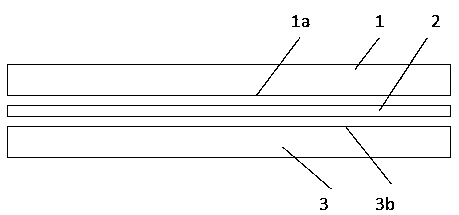

[0018] Such as figure 1 As shown, the self-lubricating material of the present invention is composed of a sliding layer 1, an adhesive layer 2 and a supporting layer 3, the adhesive layer 2 is arranged between the sliding layer 1 and the supporting layer 3, and the sliding layer 1 and the supporting layer 3 Bonding is connected, and its preparation method comprises the steps:

[0019] 1. Select the twill fabric with a thickness of 0.25mm, PTFE fiber and aramid fiber mixed (PTFE fiber mass content is 40%) as the sliding layer 1, wherein the breaking strength of the PTFE fiber is 0.7cN / dtex, and the breaking strength of the aramid fiber is 15cN / dtex.

[0020] 2. A cold-rolled carbon steel plate with a thickness of 1.25mm is selected as the support layer 3, and its bonding surface 3b is roughened, and the roughness Ra=3.0 μm. Immerse the adhesive surface 1a of the fabric sliding layer 1 and the adhesive surface 3b of the steel plate support layer with an ethanol solution of γ-(...

Embodiment 2

[0024] Except that the mass content of PTFE fibers in the sliding layer is 80%, the rest are the same as in Example 1. The resulting peel strength was 1.7 N / mm.

Embodiment 3

[0026] The self-lubricating material of the present invention is prepared by the following method:

[0027] 1. Select a plain weave fabric with a thickness of 0.2mm, PTFE fiber and high-strength polyester mixed (mass ratio 1:1) as the sliding layer, in which the breaking strength of PTFE fiber is 0.7cN / dtex, and the breaking strength of high-strength polyester is 4.1cN / dtex dtex.

[0028] 2. A stainless steel plate with a thickness of 2.0 mm is selected as the support layer, and its bonding surface 3 b is sandblasted with a roughness Ra=2.5 μm. The adhesive surface 1a of the fabric sliding layer and the adhesive surface 3b of the steel plate support layer were sprayed with an ethanol solution of 3-mercaptopropyltrimethoxysilane with a mass content of 10%, and then placed in an oven at 100°C to dry completely.

[0029]3. Select maleic anhydride grafted polypropylene as the binder, and add graphite powder with a mass content of 5% and γ-(2,3-glycidoxy)propyltrimethoxysilane wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com