Coiled material for AGV vehicle-mounted environment and preparation method of material

A coil, environment technology, applied in chemical instruments and methods, epoxy resin glue, adhesive types, etc., can solve other problems such as performance needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

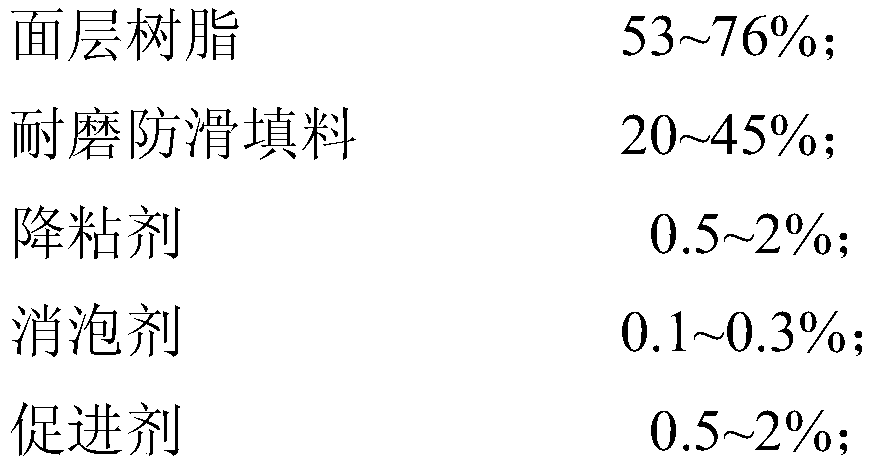

[0088] 1. Preparation of surface coating

[0089] Preparation of component A, 64.5 parts of phenolic epoxy vinyl ester resin DERAKANE 470; 33 parts of wear-resistant and anti-skid filler; 0.8 parts of viscosity reducer BYK-P 2710; 0.2 parts of defoamer BYK066N; 1.5 parts of accelerator naphthene cobalt acid; after stirring evenly, filter to obtain component A of surface coating;

[0090] Among them, the wear-resistant anti-skid filler is composed of: 20 parts of glass fiber powder, 35 parts of chopped glass fiber, 40 parts of TPU powder, and 5 parts of ternary vinyl chloride resin powder.

[0091] B component is curing agent methyl ethyl ketone peroxide;

[0092] AB components are mixed according to 100:2, and stirred evenly to prepare the top coat;

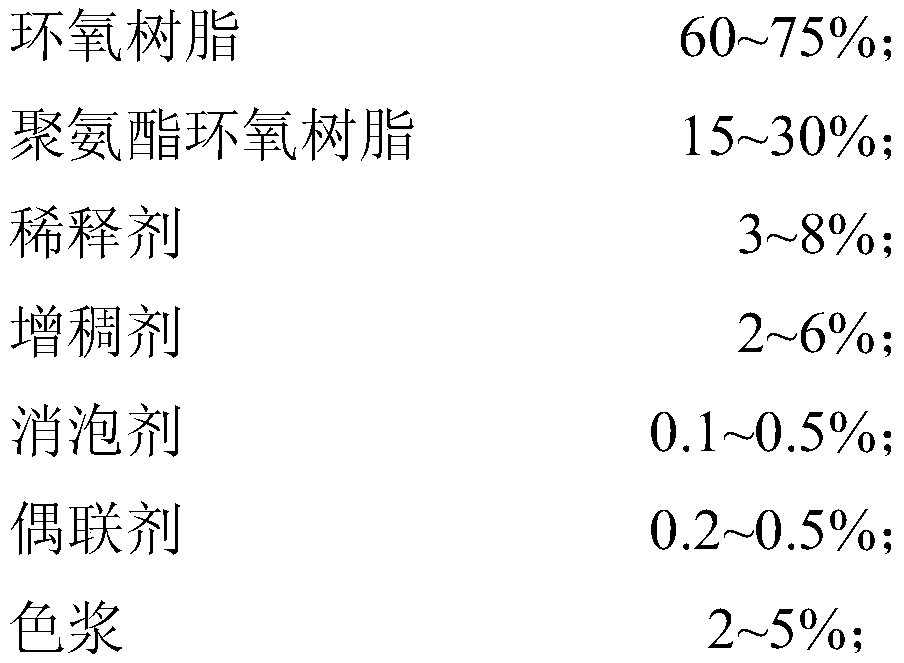

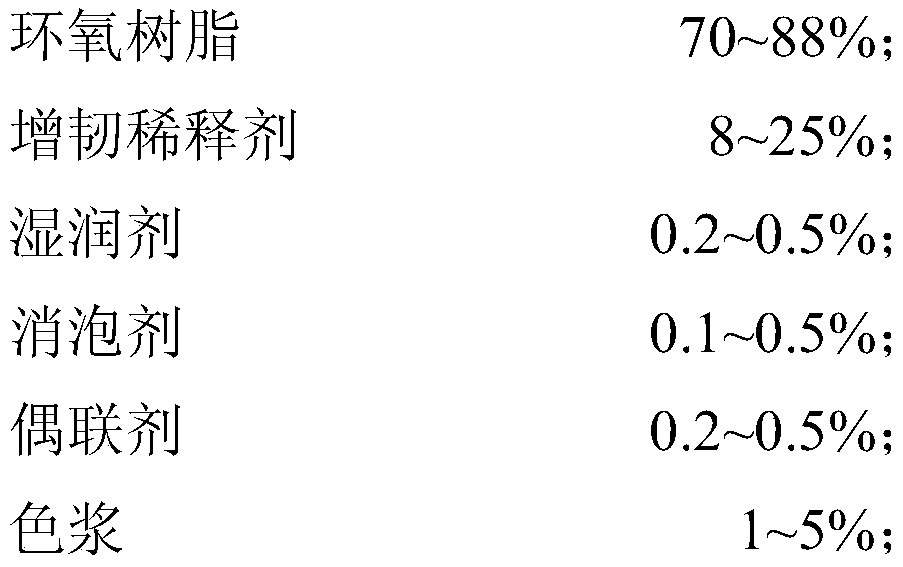

[0093] 2. Preparation of viscous coating

[0094] Preparation of component A: 67 parts of epoxy resin NPEF-128; 18 parts of polyurethane epoxy resin KTM832; 5 parts of diluent benzyl alcohol; 6 parts of thickener hydrophilic f...

Embodiment 2

[0111] 1. Preparation of surface coating

[0112] Preparation of component A, 67.8 parts of bisphenol A type epoxy vinyl ester resin is DERAKANE411; 30 parts of wear-resistant and anti-skid filler; 1 part of viscosity reducer S-3201; 0.2 parts of defoamer BYK066N; 1 part of accelerator ring Cobalt alkanoate; after stirring evenly, filter to obtain component A of the surface coating;

[0113] Among them, the wear-resistant anti-slip filler is composed of: 20 parts of glass fiber powder, 30 parts of chopped glass fiber, 40 parts of TPU powder, and 10 parts of ternary vinyl chloride resin powder.

[0114] Component B is the curing agent dibenzoyl peroxide;

[0115] AB components are mixed according to 100:2.5, and stirred evenly to prepare the surface coating;

[0116] 2. Preparation of viscous coating

[0117] Preparation of component A: 70 parts of epoxy resin NPEF-70; 15 parts of polyurethane epoxy resin KTM832; 6 parts of diluent propylene oxide butyl ether; 5 parts of thi...

Embodiment 3

[0134] This embodiment is identical with embodiment 1 except that the type of surface layer resin adopted in the surface layer coating is different, that is, the bisphenol-A epoxy vinyl resin MFE-2 of Huachang brand is used.

[0135] After testing: surface hardness 4H; coefficient of friction 0.75; wear resistance 0.003g; surface roughness Ra 0.012; flexibility φ32mm (but the test pass rate of flexibility is about 50%); residual sag of compression resistance 0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com