Self-healing leakage-proof inorganic-organic nano composite coating for natural gas pipelines

A technology of natural gas pipelines and inorganic nanometers, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of easy curing and condensation, waste of time, manpower and material resources, and many materials, and achieve enhanced surface adhesion. Effect of surface roughness and corrosion reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

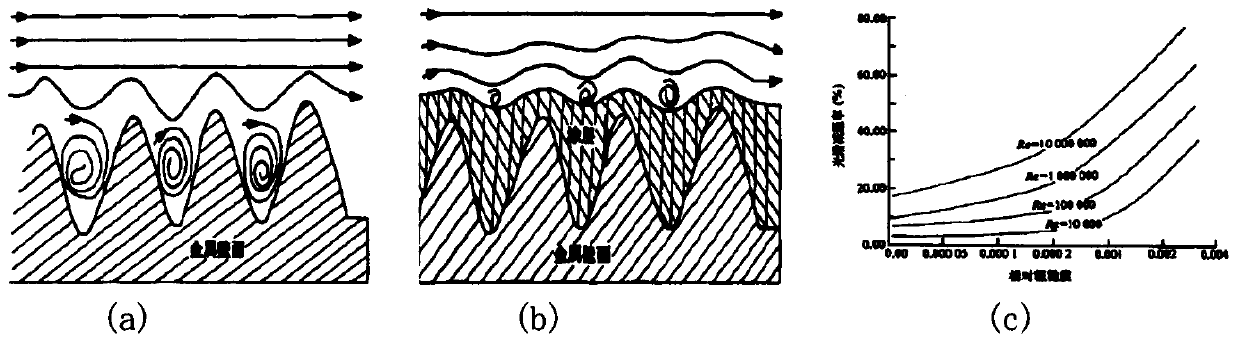

[0041] In order to reduce the occurrence of natural gas pipeline explosion accidents, aiming at the surface roughness and durability of the inner coating of natural gas pipelines, computer simulation technology is used to analyze the failure mode of natural gas pipelines, and the factors affecting the durability of natural gas pipelines are investigated. It is possible to eliminate hidden dangers inside natural gas pipelines. Reduce the environmental impact and energy waste of natural gas leakage accidents and secondary combustion.

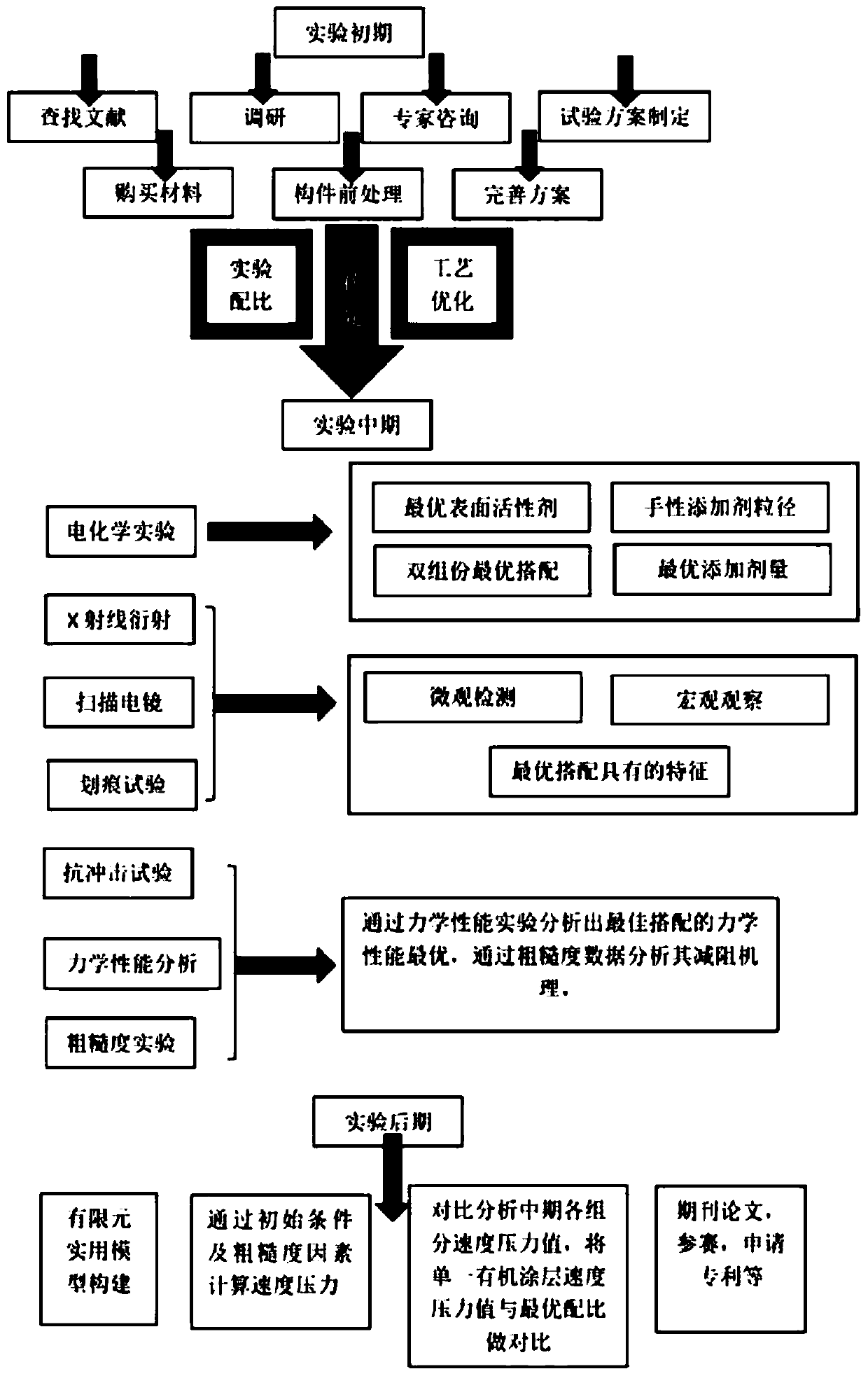

[0042] Including the screening and preparation of organic coatings and the screening of inorganic nano-additives and surfactants. Experimental protocol such as figure 1 Shown:

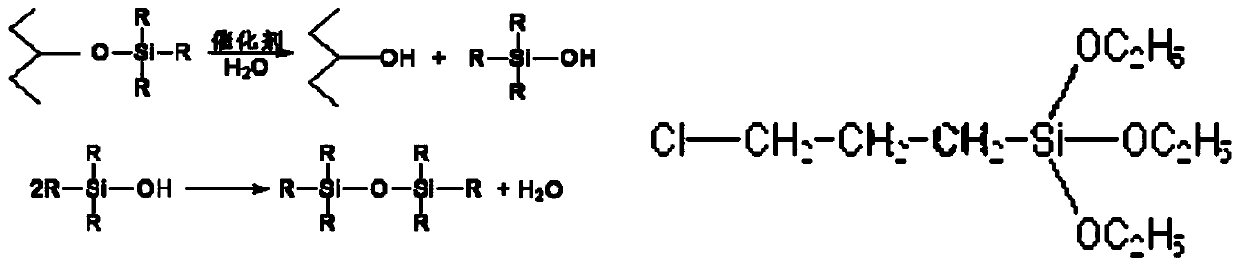

[0043] Using the electrochemical experiment POL and dynamic scanning method to test and compare the blending method prepared by acrylic paint and polyurethane organic paint with inorganic nano-additive titanium dioxide and inorganic nano-additive aluminum oxide, and scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com