Polycarbonate/silver composite surface-enhanced Raman substrate and preparation method

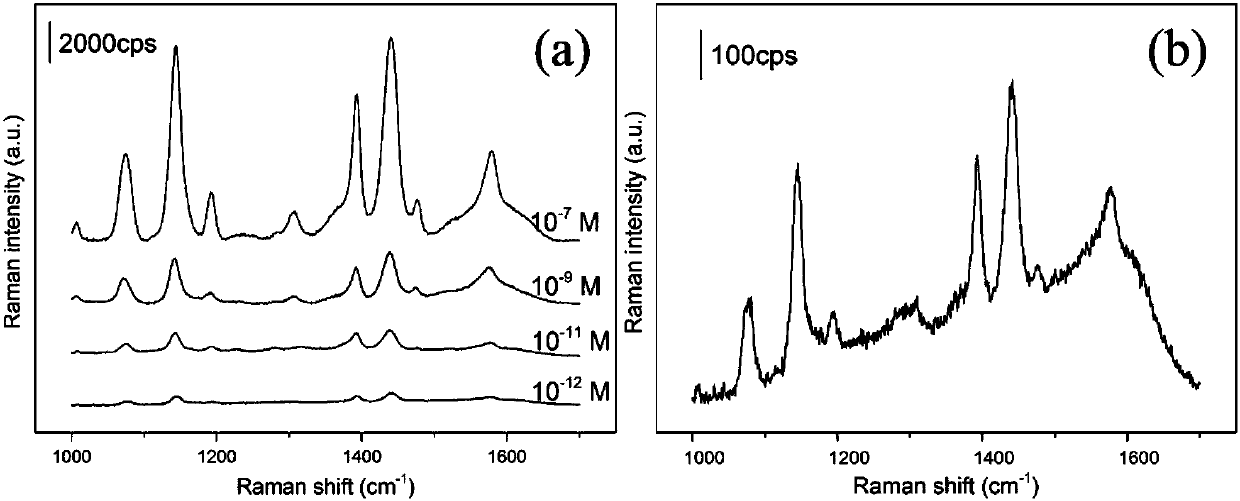

A technology of composite surface and enhanced Raman scattering, applied in the direction of Raman scattering, single-component polyester rayon, rayon manufacturing, etc., can solve the effect of size, spacing and arrangement of substrates, and the tedious preparation of silver nanoparticle substrates , difficult to prepare in large quantities, etc., to achieve the effects of low cost, high sensitivity, and improved enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

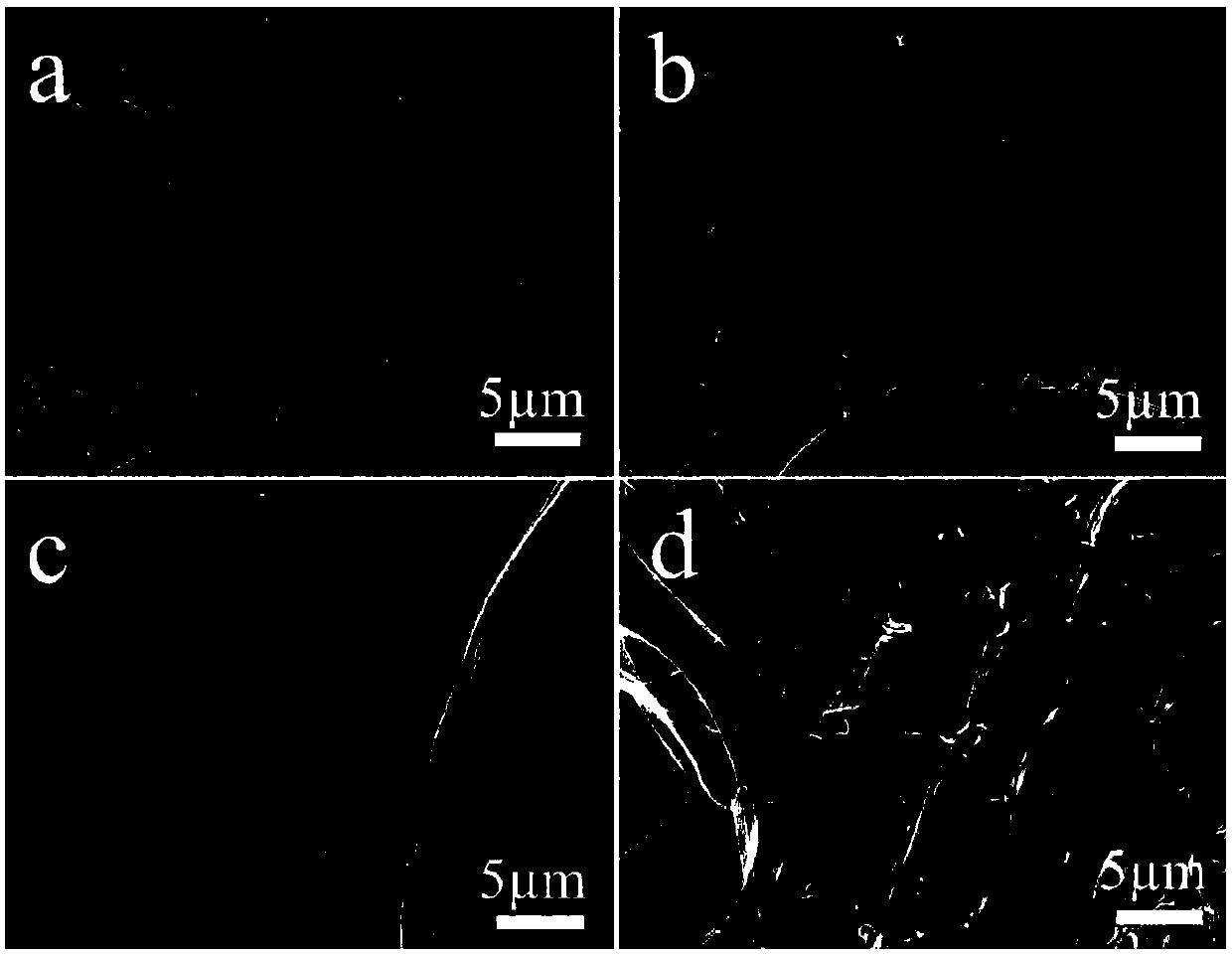

[0027] This example discloses a method for preparing a polycarbonate / silver composite surface-enhanced Raman substrate by combining electrospinning and in-situ chemical reduction technology, which specifically includes the following steps:

[0028] (1) Poly(bisphenol A) carbonate particles and silver nitrate were dissolved in a mixed solvent of tetrahydrofuran and dimethylformamide (volume ratio 6:4) according to the mass fraction of 14wt% and 4.5wt%, respectively, to prepare a polymer solution ;

[0029] (2) Fix the aluminum foil on the receiving device of the electrospinning machine, put the polymer solution into the syringe and place it on the injection table, adjust the positive high voltage to 15.0kv, the negative high voltage to -1.5kv, and the injection speed to 0.5ml / L , the experimental temperature is 30°C, the humidity is 20%, the spinning time is 5min, and polycarbonate nanofibers containing silver nitrate are obtained;

[0030] (3) Place the nanofibers obtained in...

Embodiment 2

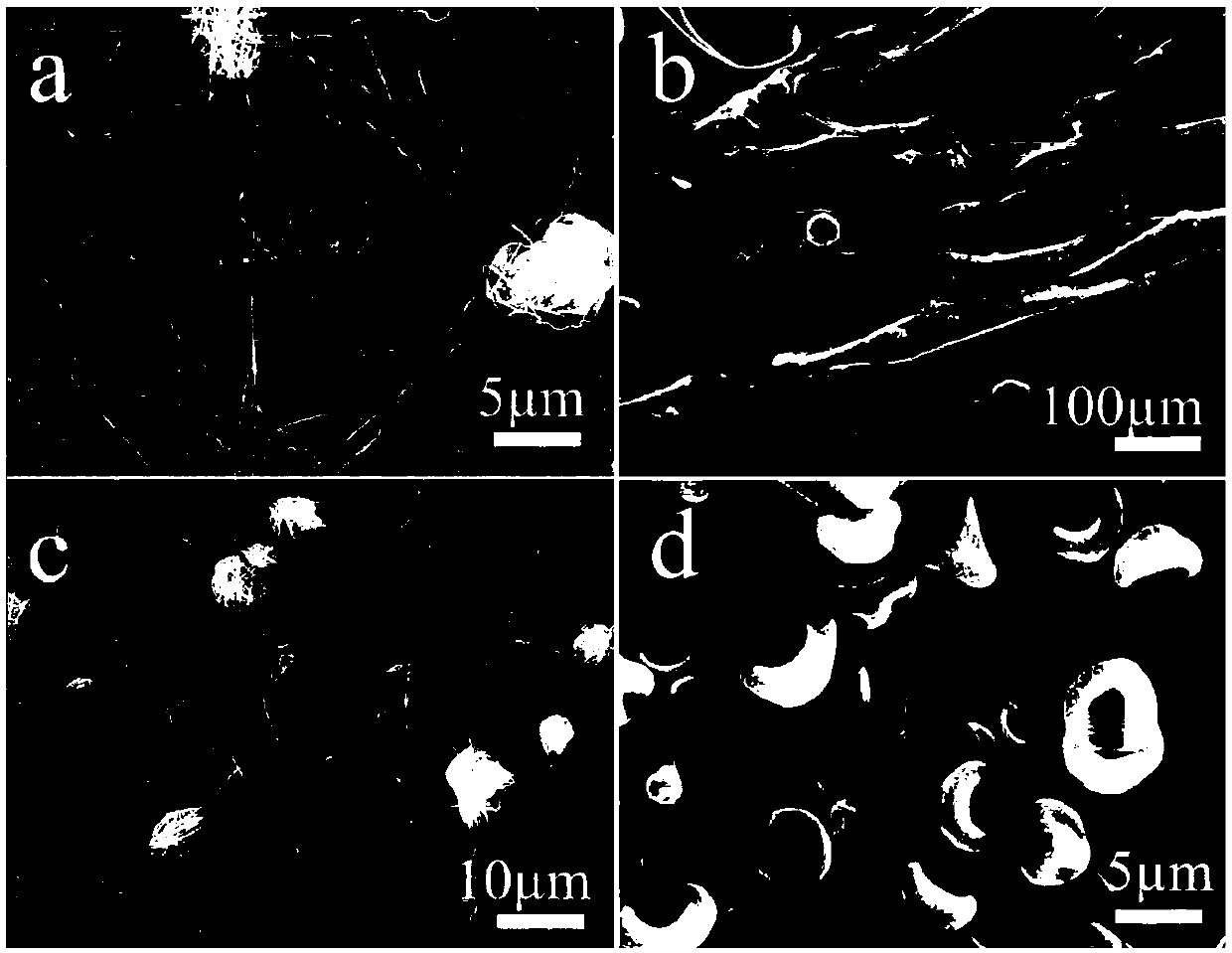

[0033] This example discloses a method for preparing a polycarbonate / silver composite surface-enhanced Raman substrate by combining electrospinning and in-situ chemical reduction technology, which specifically includes the following steps:

[0034] (1) Poly(bisphenol A) carbonate particles and silver nitrate were dissolved in a mixed solvent of tetrahydrofuran and dimethylformamide (volume ratio 6:4) according to the mass fraction of 14wt% and 2.3wt%, respectively, to prepare a polymer solution ;

[0035] (2) Fix the aluminum foil on the receiving device of the electrospinning machine, put the polymer solution into the syringe and place it on the injection table, adjust the positive high voltage to 14.0kv, the negative high voltage to -1.5kv, and the injection speed to 0.6ml / L , the experimental temperature is 40°C, the humidity is 25%, and the spinning time is 10min, and polycarbonate nanofibers containing silver nitrate are obtained;

[0036] (3) The nanofibers obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com