Preparation method and application of alpha-MnO2@delta-MnO2 supercapacitor electrode material

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

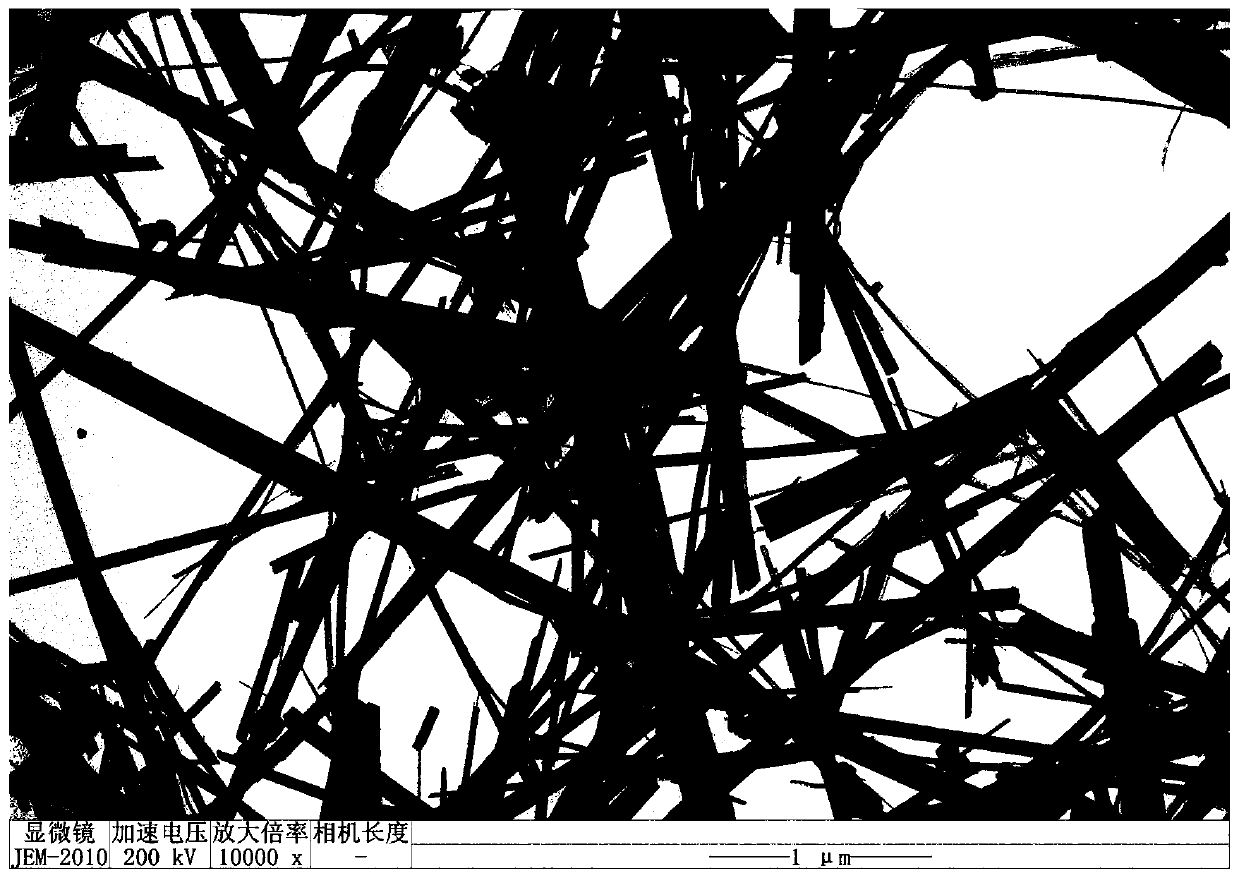

[0031] 1. Potassium permanganate (KMnO 4 ) and manganese carbonate (MnCO 3 ), add deionized water, and stir at room temperature for 30 min. Weigh 1 mmol of cobalt salt, add it into the mixture, stir evenly, and sonicate at room temperature for 20 min. The mixture was transferred to a polytetrafluoroethylene reactor and reacted at 100°C for 8h. After the reaction, cool to room temperature, centrifuge with water and ethanol several times, and dry, the resulting product is α-MnO 2 . from figure 1 It can be seen that the prepared α-MnO 2 The nanowires are uniform in length. figure 2 As can be seen in α-MnO 2 The nanowires are less than 300nm in diameter. image 3 Uniform lattice fringes indicate that the product is a single-phase material, which is consistent with α-MnO 2 The experimental results of nanowire single-phase materials are consistent. from Figure 4 It can be seen that the crystal form shows α-type MnO 2 .

[0032] 2. Potassium permanganate (KMnO 4 ) and...

Embodiment 2

[0037] 1. Potassium permanganate (KMnO 4 ) and manganese carbonate (MnCO 3 ), add deionized water, and stir at room temperature for 30 min. Weigh 3 mmol of cobalt salt, add it into the mixture, stir evenly, and sonicate at room temperature for 20 min. The mixture was transferred to a polytetrafluoroethylene reactor and reacted at 110°C for 7h. After the reaction, cool to room temperature, centrifuge with water and ethanol several times, and dry, the resulting product is α-MnO 2 . from Image 6 It can be seen that with the increase of cobalt salt doping amount, α-MnO 2 The nanowires start to bend. from Figure 7 It can be seen that the CV curves present a similar rectangular shape, indicating that the material has good electrochemical properties. Figure 8 After calculation, α-MnO 2 The specific capacitance of the nanowire is about 150F g -1 .

[0038] 2. Potassium permanganate (KMnO 4 ) and manganese carbonate (MnCO 3 ), add deionized water, and stir at room tempe...

Embodiment 3

[0040] 1. Potassium permanganate (KMnO 4 ) and manganese carbonate (MnCO 3 ), add deionized water, and stir at room temperature for 30 min. Weigh 1 mmol of cobalt salt, add it into the mixture, stir evenly, and sonicate at room temperature for 20 min. The mixture was transferred to a polytetrafluoroethylene reactor and reacted at 120°C for 6h. After the reaction, cool to room temperature, centrifuge with water and ethanol several times, and dry, the resulting product is α-MnO 2 .

[0041] 2. Potassium permanganate (KMnO 4 ) and manganese carbonate (MnCO 3 ), add deionized water, and stir at room temperature for 30 min. The α-MnO that step (1) obtains 2 Transfer to the mixed solution, further stir evenly, and sonicate for 30 min at room temperature. The mixed solution was transferred to a polytetrafluoroethylene reactor and reacted at 120°C for 6 hours. After the reaction was completed, it was cooled to room temperature, centrifuged with water and ethanol for several ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com