Preparation method and application of Nd-MOFs gas adsorption material

A gas adsorption and ligand technology, applied in the field of composite materials, can solve the problems of easy desorption of activated carbon, low recycling rate, high cost of use, etc., and achieve the effect of wide sources, excellent adsorption effect and low recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

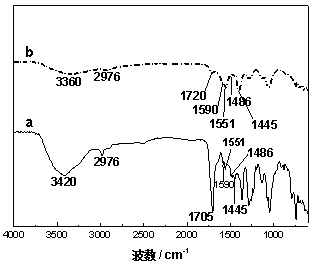

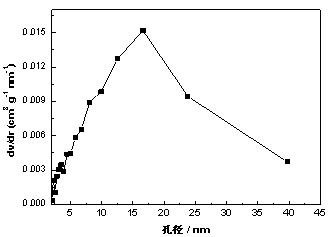

[0043] A preparation method of Nd-MOFs gas adsorption material, including ligand AGE synthesis, material synthesis,

[0044] The ligand AGE synthesis specifically includes the following steps:

[0045] Accurately weigh 10.5 g of phthalic anhydride and pour it into a flat-bottomed flask, add 40 mL of acetone solution, stir magnetically, and dissolve it fully at 30°C, then add 4.5 g of methyl-α-D-galactopyran For glucoside, after heating up to 60°C, add 2mL catalyst N,N-diisopropylethylamine (DIEA), mix well, heat and stir, and reflux for 8 hours, cool the obtained liquid to room temperature, add 1g of anhydrous sulfuric acid Magnesium drying, filtration, and the obtained filtrate was evaporated to remove the acetone solvent by using a rotary evaporator at 58°C to obtain a viscous colorless liquid that is the ligand AGE;

[0046] The material synthesis specifically includes the following steps:

[0047] Ligand solution preparation: accurately weigh 5.5 g of the above-mentioned...

Embodiment 2

[0054] A preparation method of Nd-MOFs gas adsorption material, including ligand AGE synthesis, material synthesis,

[0055] The ligand AGE synthesis specifically includes the following steps:

[0056] Accurately weigh 12.5 g of phthalic anhydride and pour it into a flat-bottomed flask, add 55 mL of acetone solution, stir magnetically, and dissolve it fully at 50°C, then add 5.5 g of methyl-α-D-galactopyranoside , after heating up to 80°C, add 8mL catalyst N,N-diisopropylethylamine (DIEA), mix well, heat and stir, reflux for 8.5 h, cool the resulting liquid to room temperature, add 3 g of anhydrous sulfuric acid Magnesium drying, filtration, and the obtained filtrate was evaporated to remove the acetone solvent by using a rotary evaporator at 62°C to obtain a viscous colorless liquid that is the ligand AGE;

[0057] The material synthesis specifically includes the following steps:

[0058] Ligand solution preparation: accurately weigh 7.0 g of the above-mentioned ligand AGE ...

Embodiment 3

[0065] A preparation method of Nd-MOFs gas adsorption material, including ligand AGE synthesis, material synthesis,

[0066] The synthesis of the ligand AGE specifically includes the following steps: accurately weigh 11.5 g of phthalic anhydride and pour it into a flat-bottomed flask, add 50 mL of acetone solution, stir magnetically, fully dissolve it at 40°C, and then add 5 g Methyl-α-D-galactopyranoside, after heating up to 75 °C, add 4 mL of catalyst N, N-diisopropylethylamine (DIEA), mix well, heat and stir, and reflux for 9 h, the obtained Cool the liquid to room temperature, add an appropriate amount of 2g of anhydrous magnesium sulfate to dry, filter, and evaporate the acetone solvent from the obtained filtrate at 60°C using a rotary evaporator to obtain a viscous colorless liquid that is the ligand AGE;

[0067] The material synthesis specifically includes the following steps:

[0068] Ligand solution preparation: accurately weigh 6.25 g of the above-mentioned ligand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com