Solid acid catalyst as well as preparation method thereof and preparation method of hydroxy phenylglycine

A solid acid catalyst and ammoniating agent technology, which is applied in the direction of catalyst activation/preparation, organic compound preparation, cyanide reaction preparation, etc., can solve the problems of long process route, long reaction time, cumbersome operation, etc., to reduce pollution, The effect of high reuse rate and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of solid acid catalyst, comprises the following steps:

[0029] Perform hydrothermal synthesis reaction of silica sol, aluminum hydroxide and inorganic strong base to obtain hydrothermal synthesis product system;

[0030] performing an ion exchange reaction with the hydrothermal synthesis product system and ammonium nitrate solution to obtain a solid acid catalyst precursor;

[0031] The solid acid catalyst precursor is calcined to obtain a solid acid catalyst.

[0032] In the invention, silica sol, aluminum hydroxide and inorganic strong base are subjected to hydrothermal synthesis reaction to obtain a hydrothermal synthesis product system.

[0033] In the present invention, the hydrothermal synthesis reaction of silica sol, aluminum hydroxide and inorganic strong base preferably specifically includes first mixing the silica sol and aluminum hydroxide uniformly to obtain a gel, and then adding The inorganic strong b...

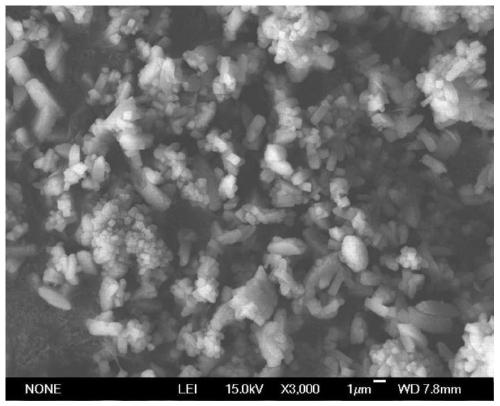

Embodiment 1

[0050] Mix 1.0 mol of silica sol, 160 mol of aluminum hydroxide and 0.2 mol of sodium hydroxide, and carry out hydrothermal synthesis reaction at 200°C for 40 hours to obtain a hydrothermal synthesis product system; add 100 mL of 0.3 mol / L of ammonium nitrate solution, carried out ion exchange reaction 3 times at 70°C, dried at 120°C for 6h to obtain a solid acid catalyst precursor; roasted the solid acid catalyst precursor at 520°C for 5h, and ground to The particle size is 0.8 μm, and a solid acid catalyst is obtained, and the acidity of the solid acid catalyst is H 0 ≤-3, the acid content is 1.56mmol / g cat.

Embodiment 2

[0052] Mix 1.0 mol of silica sol, 20 mol of aluminum hydroxide and 0.03 mol of sodium hydroxide, and conduct a hydrothermal synthesis reaction at 150°C for 12 hours to obtain a hydrothermal synthesis product system; add 50 mL of 0.1 mol / L ammonium nitrate solution, ion exchange reaction was carried out 3 times at 60°C, and dried at 100°C for 8h to obtain a solid acid catalyst precursor; the solid acid catalyst precursor was roasted at 450°C for 3h, and ground to The particle size is 0.5 μm, and a solid acid catalyst is obtained, and the solid acid catalyst H 0 ≤-3, the acid content is 1.35mmol / g cat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com