A nitrogen-doped porous carbon-supported titanium dioxide photocatalyst and its preparation method and application

A technology of photocatalyst and titanium source, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of high photogenerated electron-hole recombination rate, complex pollution, etc., and achieve high photoreaction efficiency, chemical Stable properties and the effect of inhibiting electron-hole recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

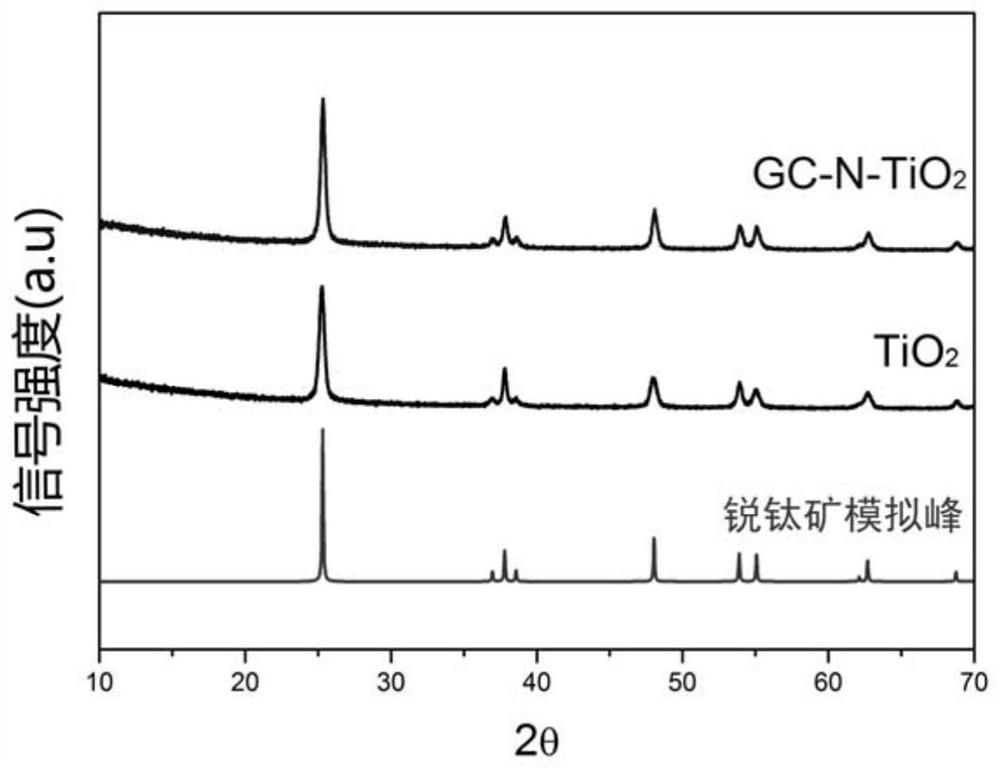

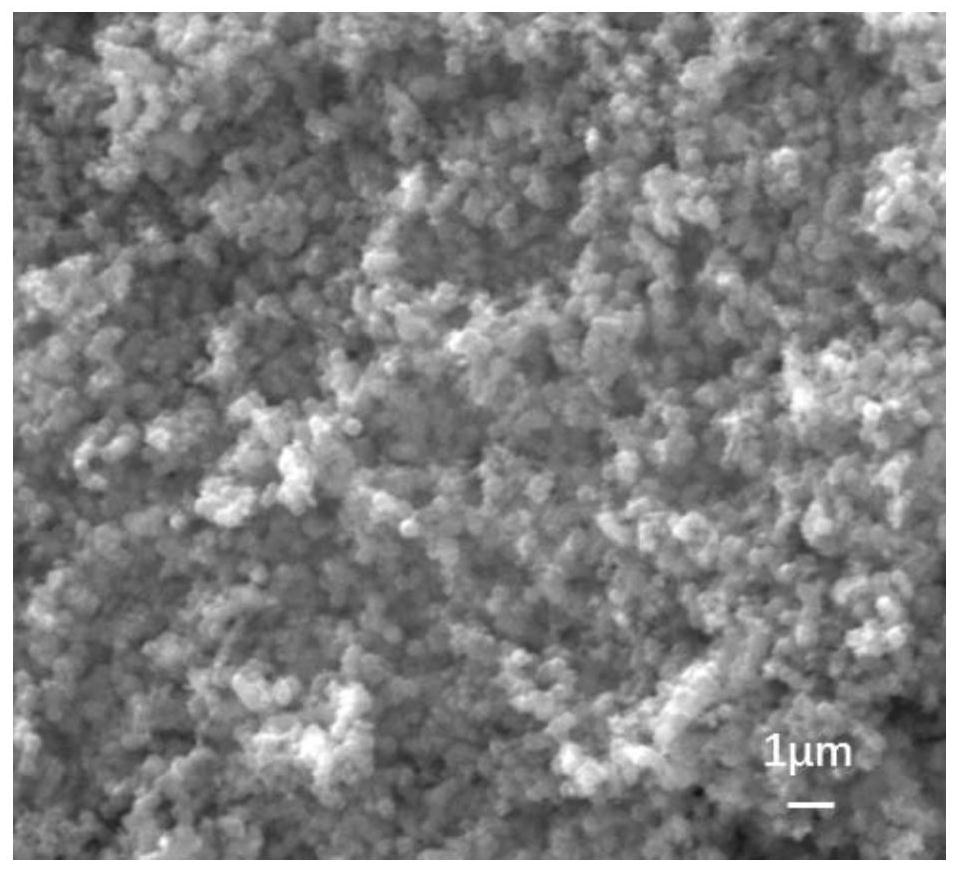

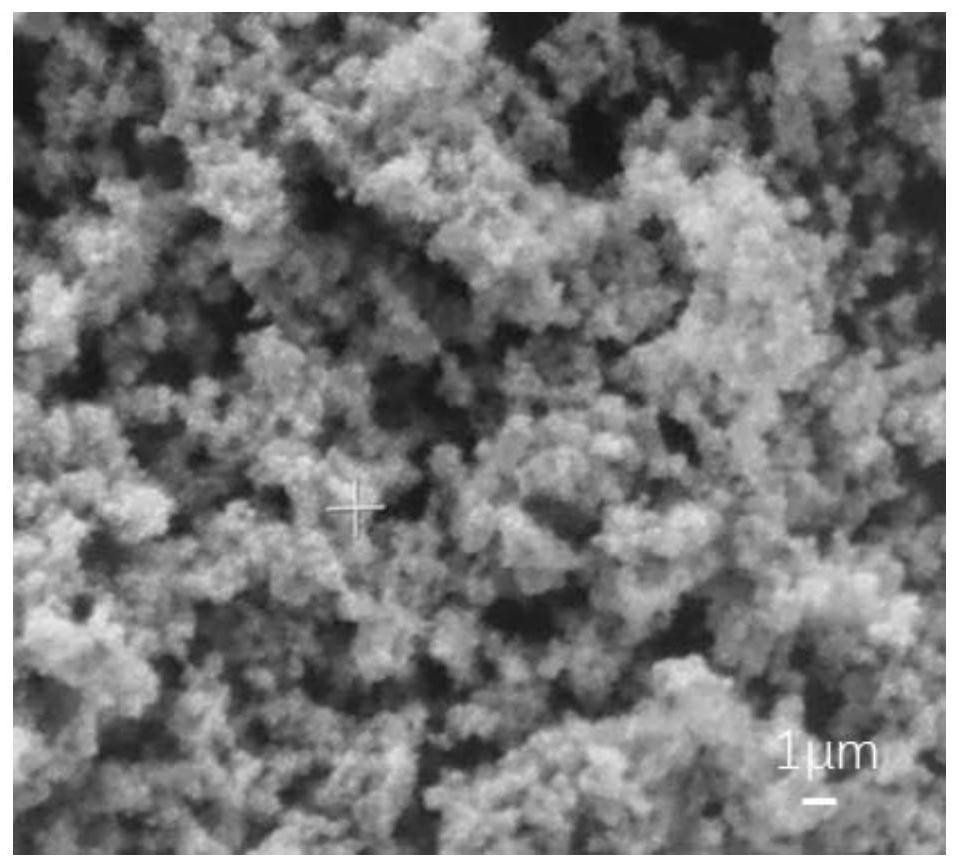

[0035] Preparation of GC-N: 5.95 g of zinc nitrate hexahydrate and 6.16 g of 2-methylimidazole were added to 300 mL of methanol, stirred at room temperature for 24 h, centrifuged, washed with methanol, and dried in an oven at 60 °C for 8 h to obtain Organometallic framework ZIF-8. Put ZIF-8 in a porcelain crucible, in a tube furnace at a heating rate of 2°C / min under N 2 The temperature was raised to 920 °C under the atmosphere, and calcined at 920 °C for 3 h at the same time. After cooling to room temperature, nitrogen-doped porous carbon material GC-N was obtained.

[0036] GC-N-TiO 2 Preparation: Disperse 0.01 g GC-N in 40 mL of absolute ethanol, ultrasonically disperse for 30 min to form solution A, add 2 mL of ammonia water, stir at room temperature for 10 min to form solution B, then add 5 mL of isopropyl titanate Add it into solution B, and keep stirring for 20 min to form a mixed solution C. Transfer the mixed solution C to the lining of the polytetrafluoroethylene ...

Embodiment 2

[0038] Preparation of GC-N: 5.95 g of zinc nitrate hexahydrate and 6.16 g of 2-methylimidazole were added to 300 mL of methanol, stirred at room temperature for 24 h, centrifuged, washed with methanol, and dried in an oven at 60 °C for 8 h to obtain Organometallic framework ZIF-8. Put ZIF-8 in a porcelain crucible, in a tube furnace at a heating rate of 2°C / min under N 2 The temperature was raised to 920 °C under the atmosphere, and calcined at 920 °C for 3 h at the same time. After cooling to room temperature, nitrogen-doped porous carbon material GC-N was obtained.

[0039] GC-N-TiO 2 Preparation: Disperse 0.01 g GC-N in 40 mL of absolute ethanol, ultrasonically disperse for 30 min to form solution A, add 2 mL of ammonia water, stir at room temperature for 10 min to form solution B, then add 1 mL of isopropyl titanate Add it into solution B, and keep stirring for 20 min to form a mixed solution C. Transfer the mixed solution C to the lining of the polytetrafluoroethylene ...

Embodiment 3

[0041] Preparation of GC-N: 5.95 g of zinc nitrate hexahydrate and 6.16 g of 2-methylimidazole were added to 300 mL of methanol, stirred at room temperature for 24 h, centrifuged, washed with methanol, and dried in an oven at 60 °C for 8 h to obtain Organometallic framework ZIF-8. Put ZIF-8 in a porcelain crucible, in a tube furnace at a heating rate of 2°C / min under N 2 The temperature was raised to 920 °C under the atmosphere, and calcined at 920 °C for 3 h at the same time. After cooling to room temperature, nitrogen-doped porous carbon material GC-N was obtained.

[0042] GC-N-TiO 2 Preparation: Disperse 0.01 g GC-N in 40 mL of absolute ethanol, ultrasonically disperse for 30 min to form solution A, add 2 mL of ammonia water, stir at room temperature for 10 min to form solution B, then add 10 mL of isopropyl titanate Add the ester to solution B, and continue to stir for 20 min to form a mixed solution C. Transfer the mixed solution C to the lining of a polytetrafluoroet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com