Low-VOC (volatile organic compound) polypropylene material for vehicles and preparation method of polypropylene material

A polypropylene material and polypropylene technology, applied in the field of low-VOC automotive polypropylene material and its preparation, can solve the problems of increasing reaction activity, aggravating the degradation of polypropylene resin, and rusting of extruders, so as to increase the concentration of reactants, The effect of reducing the dosage and improving the degradation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

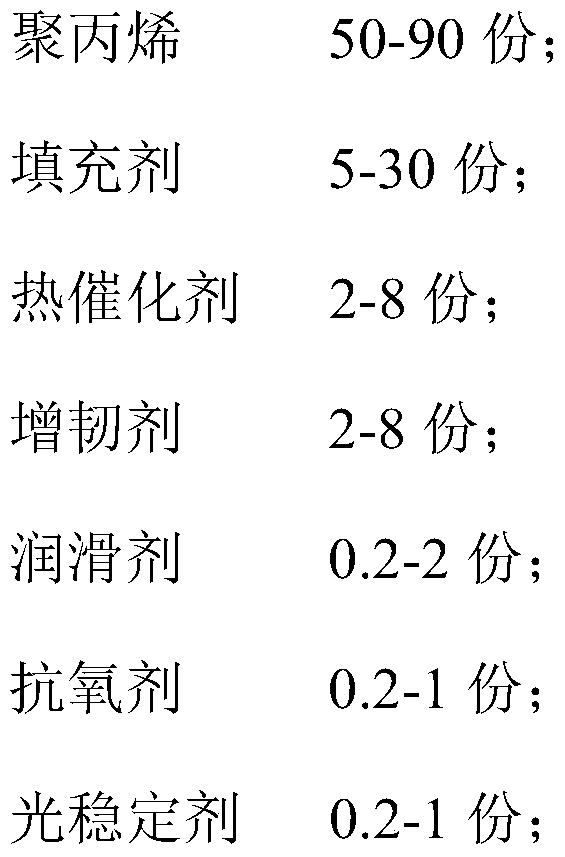

Method used

Image

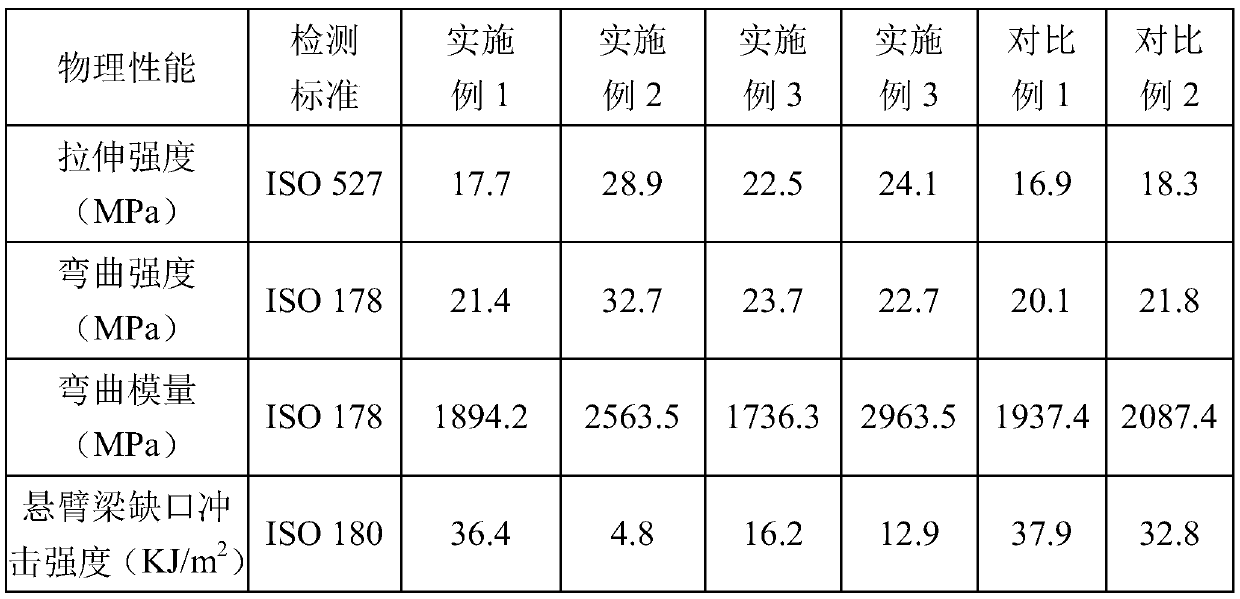

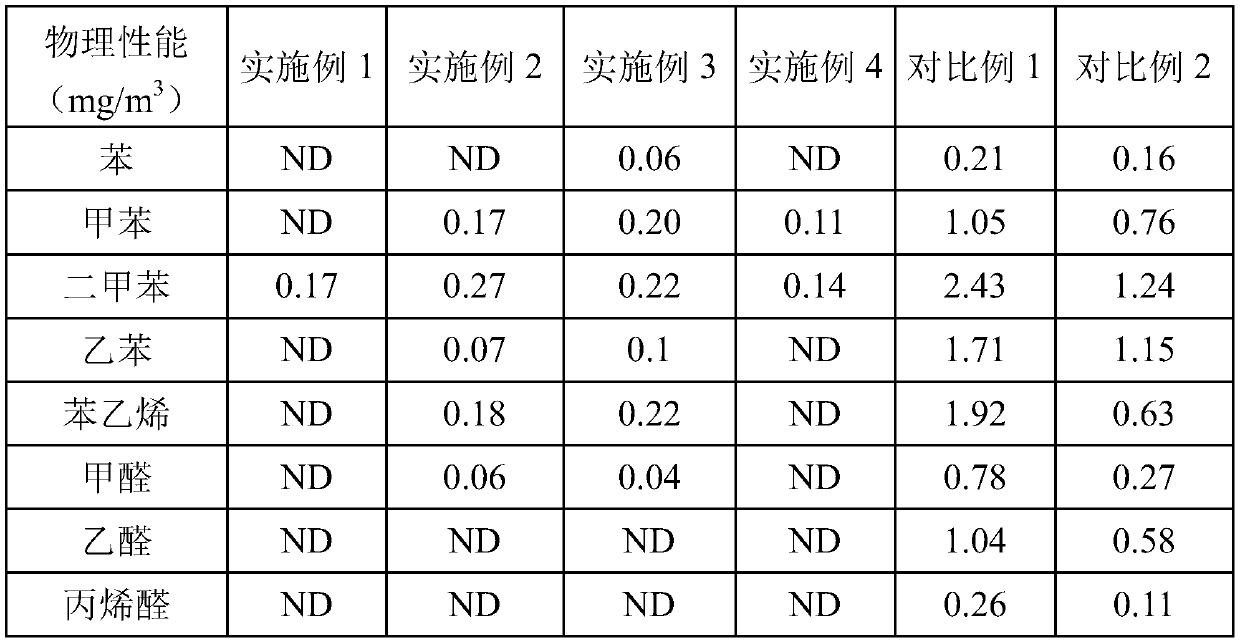

Examples

Embodiment 1

[0032] Prepare hot catalyst:

[0033] Mix 500g of zeolite molecular sieve with 5000ml of distilled water and stir for 1h; add 514ml of 0.05mol / L chloroplatinic acid aqueous solution, stir at room temperature for 2h, place in a muffle furnace, dry at 105°C, and grind finely; then It was calcined in air at 400°C for 2h, and then in H 2 Reduction at 300°C for 3 hours in the air stream to obtain a hot catalyst with a Pt loading of 1%; take 500g of the loaded hot catalyst and add it to a high mixer, mix it at 110°C for 5 minutes at 1200r / min, add 4g of aluminate Combined agent, continue to mix at high speed for 5 minutes.

[0034] Preparation of low-VOC automotive polypropylene materials:

[0035] Take by weighing 68 parts of copolymerized polypropylene, 20 parts of talcum powder, 4 parts of thermal catalysts, 7 parts of ethylene-octene copolymers, 0.4 parts of ethylene bis stearamide, 0.3 parts of antioxidant 1010 and 0.3 parts by weight The light stabilizer is added to the mix...

Embodiment 2

[0037] Prepare hot catalyst:

[0038] Mix 500g of porous aluminum hydroxide with 5000ml of distilled water and stir for 1 hour; add 770ml of aqueous solution of chloroplatinic acid with a concentration of 0.01mol / L, stir at room temperature for 3 hours, place in a muffle furnace, dry at 105°C, and grind finely; It was then calcined in air at 400°C for 3 h, and then heated in H 2 Reduction at 300°C for 2h in the air stream to obtain a hot catalyst with a Pt loading of 0.3%; take 500g of the loaded hot catalyst and add it to a high mixer, and mix it at 1400r / min for 5min at 80°C; then add 5g of rare earth coupling agent, and continue to mix at high speed for 8 minutes.

[0039] Preparation of low-VOC automotive polypropylene materials:

[0040]Weigh 75 parts of homopolypropylene, 13 parts of mica, 6 parts of thermal catalyst, 4 parts of ethylene-propylene copolymer, 1 part of pentaerythritol stearate, 0.5 part of antioxidant 1076 and 0.5 part of light stable Add the agent int...

Embodiment 3

[0042] Prepare hot catalyst:

[0043] Mix 500g of medical stone with 5000ml of distilled water and stir for 1h; add 770ml of 0.1mol / L chloroplatinic acid aqueous solution, stir at room temperature for 1h, place in a muffle furnace, dry at 105°C, and grind finely; then It was calcined in air at 400°C for 4 h, and then heated in H 2 Reduction at 300°C for 4 hours in the air stream to obtain a hot catalyst with a Pt loading of 3%; take 500g of the loaded hot catalyst and add it to a high mixer, and mix it at 120°C for 7 minutes at 1000r / min; then add 7.5g of titanic acid The ester coupling agent continued to mix at high speed for 6 minutes.

[0044] Preparation of low-VOC automotive polypropylene materials:

[0045] Weigh 50 parts of copolymerized polypropylene, 40 parts of homopolypropylene, 5 parts of wollastonite, 2 parts of thermal catalyst, 2 parts of propylene-alpha olefin copolymer, 0.5 part of zinc stearate, 0.3 part of antioxidant by weight 168 and 0.2 parts of light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com