Rare earth hydrogen storage alloy/borohydride composite hydrogen storage material and preparation method thereof

A technology of hydrogen storage alloys and borohydrides, which is applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of complex process and large uncertainty of hydride raw materials, and achieve the effect of simple preparation process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the rare earth hydrogen storage alloy / borohydride composite hydrogen storage material provided by the present invention comprises the following steps:

[0024] (1) Sieve the rare earth hydrogen storage alloy and borohydride raw materials so that the particle size is less than 200 meshes, and mix the rare earth hydrogen storage alloy and borohydride raw materials with a molar ratio of (20-0.05): 1;

[0025] (2) Mechanized ball milling the homogeneously mixed raw materials under a certain pressure of inert gas and / or hydrogen atmosphere;

[0026] (3) Take out the composite hydrogen storage material after ball milling, and conduct hydrolysis hydrogen production test, gaseous or electrochemical hydrogen storage test.

[0027] Among them, the rare earth hydrogen storage alloy and borohydride raw materials are screened in a glove box. The uniformly mixed raw materials are put into the ball milling tank. The main implementation parameters are: the ga...

Embodiment 1

[0030] This example is used to prepare La 2 Mg 17 / KBH 4 Composite hydrogen storage materials.

[0031] Smelting La in an induction furnace with high-purity metal La and Mg in proportion 2 Mg 17 Alloy, broken under argon protective atmosphere below 200 mesh; La 2 Mg 17 Alloy particles and KBH 4 Mix evenly at a molar ratio of 1:10, put it into a ball mill tank, control the ball-material ratio to 40:1, and seal the ball mill tank by VCR; the ball mill tank is a reducing atmosphere under pure hydrogen, and the hydrogen pressure is 0.2Mpa; The ball milling time is 4 hours, and the rotational speed of the ball mill is 200 rpm.

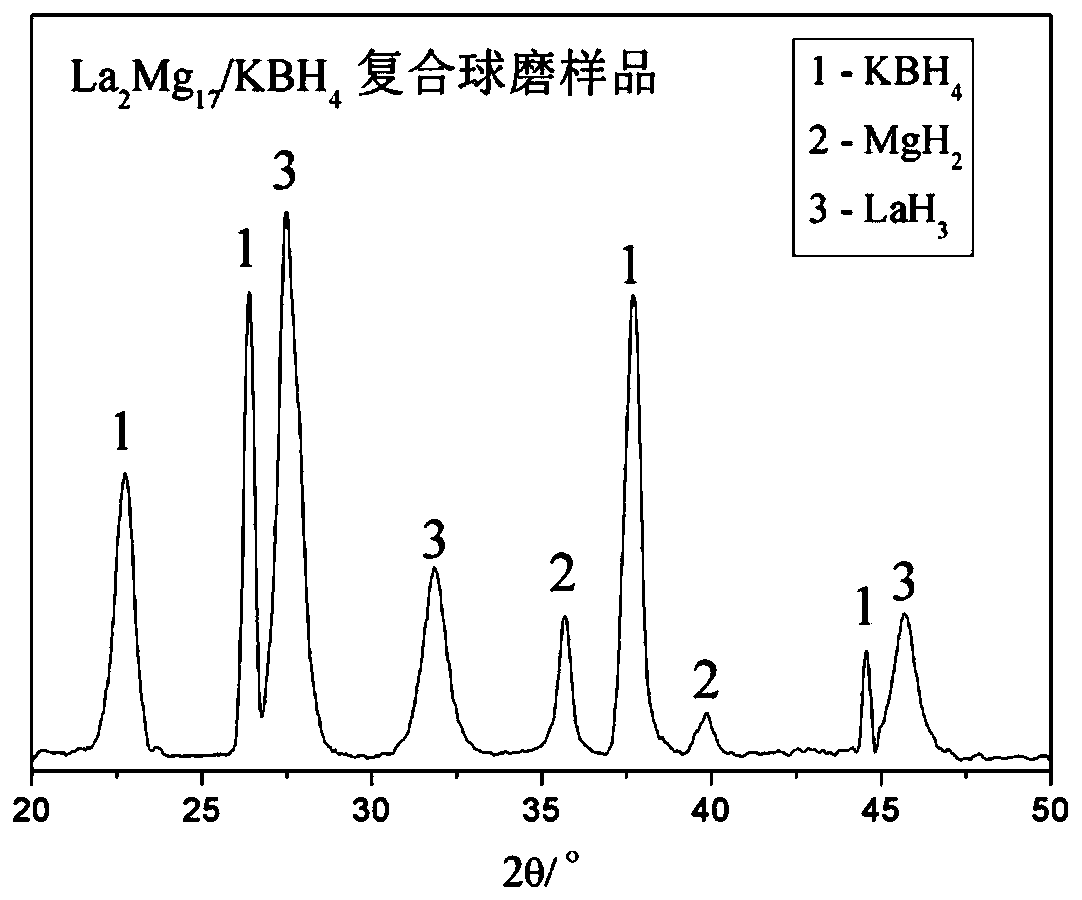

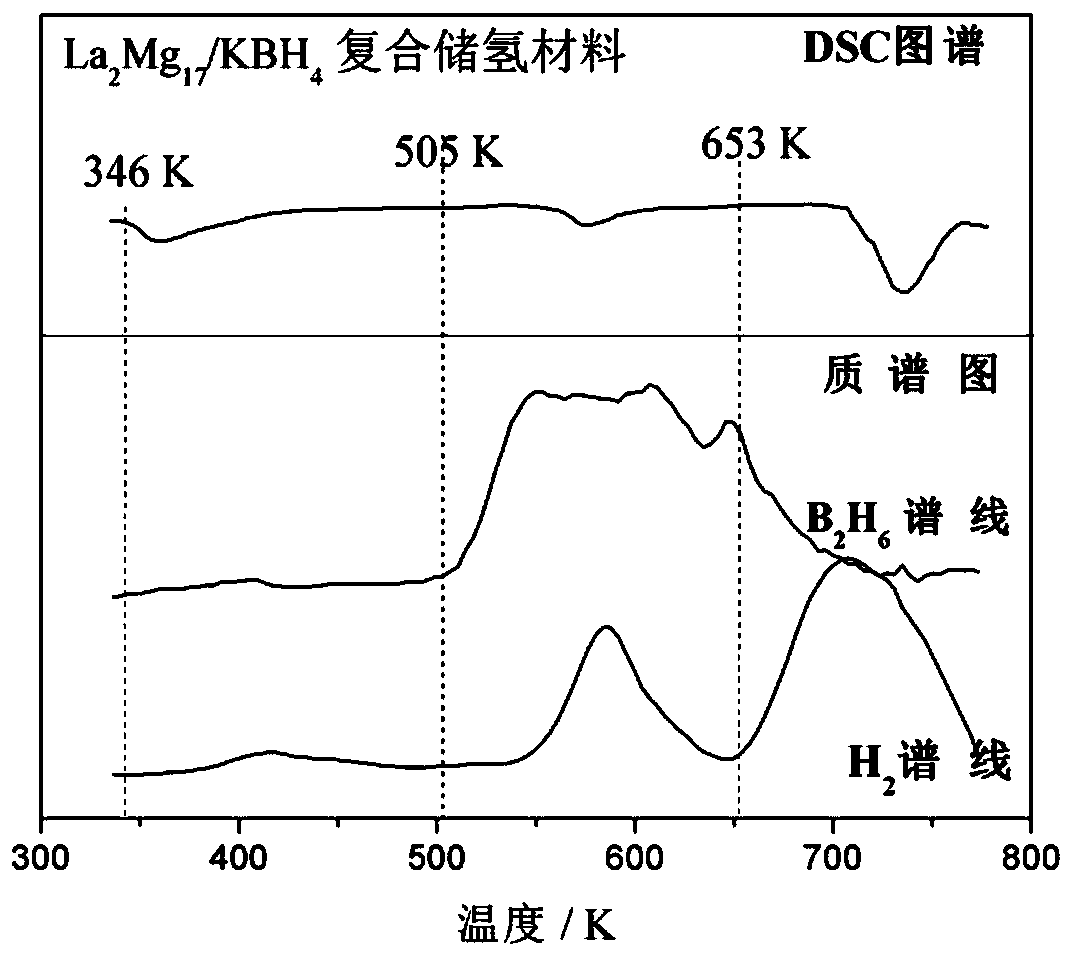

[0032] Take out the composite hydrogen storage material after ball milling in the glove box, carry out Xrd phase analysis to it, as figure 1 As shown, its bulk phase composition is KBH 4 、LaH 3 and MgH 2 . Put it into the corresponding test equipment, carry out the DSC-MS temperature rise desorption test, the test results are as follows: figur...

Embodiment 2

[0034] This example is used to prepare La 2 MgNi 9 / KBH 4 Composite hydrogen storage alloy.

[0035] La is smelted in an induction furnace with high-purity metals La, Mg and Ni in proportion 2 MgNi9 Alloy, crushed to below 200 mesh under argon protective atmosphere; La 2 MgNi 9 Alloy particles and KBH 4 Mix evenly according to the molar ratio of 10:1, put it into a ball mill tank, control the ball-material ratio to 30:1, seal the ball mill tank by VCR; the ball mill tank is a reducing atmosphere under pure hydrogen, and the hydrogen pressure is 0.4 MPa; the ball milling time is 2h, and the rotational speed of the ball mill is 400rpm.

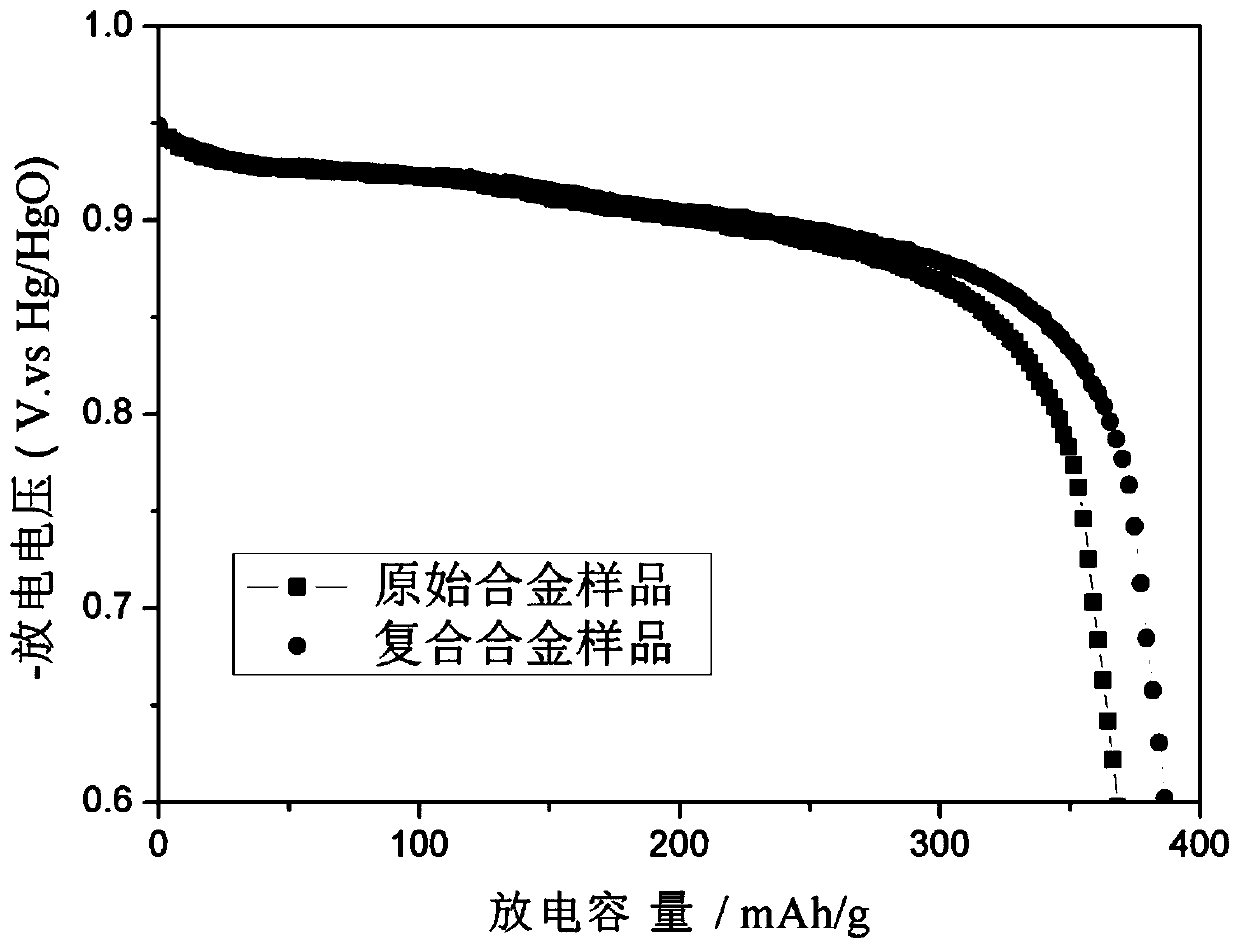

[0036] The composite hydrogen storage material after ball milling was taken out from the glove box, pressed into an electrode sheet, put into the corresponding test equipment, and tested for gas electrochemical hydrogen storage capacity. The comparison results with the electrochemical hydrogen storage capacity of the original alloy are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com