Liquid alkali-free accelerator and preparation method

An accelerator and liquid technology, applied in the field of building materials, can solve the problems of low 28d strength retention rate, insufficient comprehensive performance of the accelerator, and poor stability, and achieve solution stability and adaptability. Chlorine-free, fluorine-free, solution Good stability and adaptability, small loss of later strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

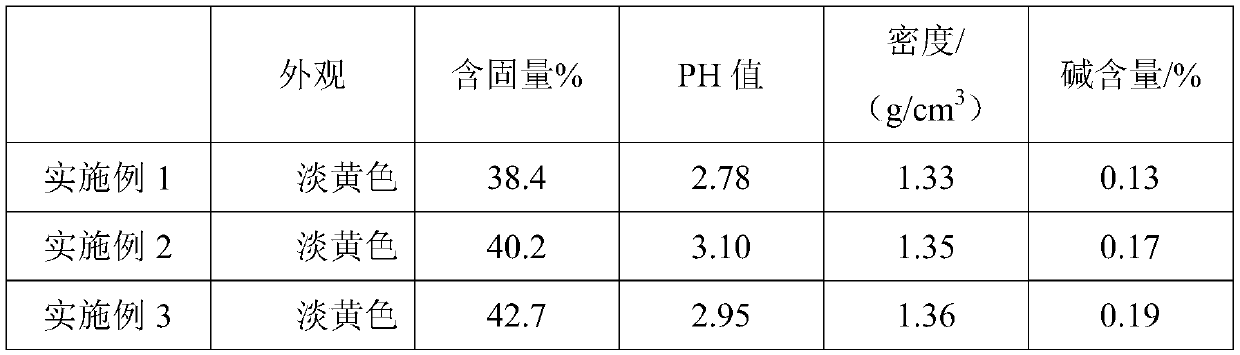

Embodiment 1

[0032] According to the above-mentioned technical scheme, the present embodiment provides a liquid alkali-free quick-setting agent, which is characterized in that, in parts by mass, it is made of the following raw materials: the mother liquor is 35%, the modifier is 20%, and the active agent is 2%, the balance is water, and the sum of the parts by weight of raw materials is 100%;

[0033] in:

[0034] The mother liquor is mixed with β-chitosan and polyaluminum iron silicate in a mass ratio of 1:1, and water is added to make a mother liquor with a mass concentration of 45%;

[0035] Modifier, in parts by mass, consists of calcium sulfoaluminate micropowder: dibutyl phthalate: polydimethyl diallyl ammonium chloride: carrot antifreeze protein: diatom powder according to 10: ( 1~2): (1~2): (3~5): (5~6) ratio made;

[0036] The molecular formula of polydimethyldiallylammonium chloride is (C 8 h 16 NCl) n , The number average molecular weight is 500,000.

[0037] The active ag...

Embodiment 2

[0048] According to the above-mentioned technical scheme, the present embodiment provides a liquid alkali-free quick-setting agent, which is characterized in that, in parts by mass, it is made of the following raw materials: 40% of the mother liquor, 25% of the modifying agent, and activating agent of 3%, the balance is water, and the sum of the parts by weight of raw materials is 100%;

[0049] In this embodiment, the mother liquor, modifier and active agent are all the same as in Embodiment 1.

[0050] The preparation method of the liquid alkali-free quick-setting agent of this embodiment is basically the same as that of Embodiment 1.

Embodiment 3

[0052] According to the above-mentioned technical scheme, the present embodiment provides a liquid alkali-free quick-setting agent, which is characterized in that, in parts by mass, it is made of the following raw materials: 45% of the mother liquor, 20% of the modifying agent, and activating agent of 5%, the remainder is water, and the sum of the parts by weight of raw materials is 100%;

[0053] In this embodiment, the mother liquor, modifier and active agent are all the same as in Embodiment 1.

[0054] The preparation method of the liquid alkali-free quick-setting agent of this embodiment is basically the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com