Anti-skid daily ceramics and preparation method thereof

A kind of technology for ceramics and daily use, which is applied in the field of preparation of daily-use ceramics, which can solve the problems of broken, non-slip ceramics, slipping and other problems, and achieve the effects of improved dispersion, excellent anti-slip effect and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

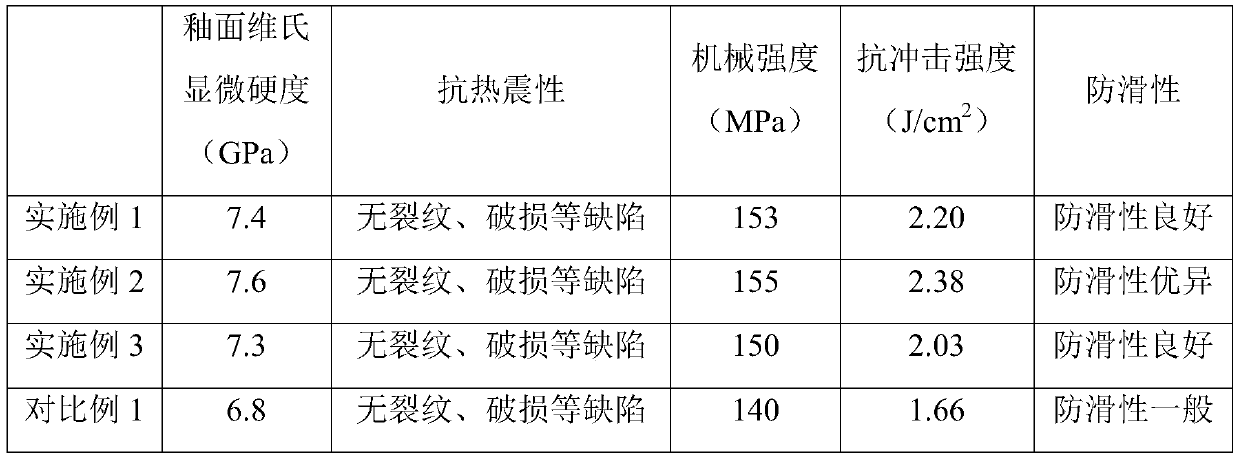

Examples

Embodiment 1

[0026] Embodiment 1: a kind of non-slip daily-use ceramics, comprising the following raw materials in parts by weight: 6 parts of halloysite, 45 parts of kaolin, 9 parts of KH791 silane coupling agent, 25 parts of potassium feldspar, 22 parts of albite, spodumene 15 parts of stone, 8 parts of silicon dioxide, 10 parts of aluminum oxide, 5 parts of lithium oxide, 7 parts of nano-titanium nitride, 20 parts of konjac glucomannan powder, 15 parts of starch, 5 parts of EVA and 12 parts of fired oyster shell powder share.

[0027] Wherein, the preparation method of the burnt oyster shell powder is as follows: putting the oyster shell powder into a high-temperature furnace at 900° C. for 70 minutes, and then cooling to room temperature to prepare the burnt oyster shell powder.

[0028] A kind of preparation method of above-mentioned non-slip daily-use ceramics, comprises the following steps:

[0029] 1) Put kaolin into the ball mill, add KH791 silane coupling agent, and ball mill fo...

Embodiment 2

[0034] Embodiment 2: a kind of non-slip daily-use ceramics, comprising the following raw materials in parts by weight: 8 parts of halloysite, 40 parts of kaolin, 11 parts of KH791 silane coupling agent, 22 parts of potassium feldspar, 30 parts of albite, spodumene 12 parts of silicon dioxide, 10 parts of silicon dioxide, 8 parts of aluminum oxide, 7 parts of lithium oxide, 5 parts of nano-titanium nitride, 22 parts of konjac glucomannan powder, 12 parts of starch, 8 parts of EVA and 10 parts of fired oyster shell powder share.

[0035] Wherein, the preparation method of the burnt oyster shell powder is as follows: put the oyster shell powder into a 950° C. high-temperature furnace and incinerate for 65 minutes, and then cool to room temperature to prepare the burnt oyster shell powder.

[0036] Wherein, the mass content of ethylene acetic acid in the EVA is preferably 20-40%.

[0037] A kind of preparation method of above-mentioned non-slip daily-use ceramics, comprises the f...

Embodiment 3

[0043] Embodiment 3: a kind of non-slip daily ceramics, comprising the following raw materials in parts by weight: 12 parts of halloysite, 35 parts of kaolin, 12 parts of KH791 silane coupling agent, 20 parts of potassium feldspar, 35 parts of albite, spodumene 10 parts of silicon dioxide, 15 parts of silicon dioxide, 6 parts of aluminum oxide, 10 parts of lithium oxide, 3 parts of nano-titanium nitride, 25 parts of konjac glucomannan powder, 10 parts of starch, 10 parts of EVA and 8 parts of fired oyster shell powder share.

[0044] Wherein, the preparation method of the burnt oyster shell powder is as follows: putting the oyster shell powder into a high-temperature furnace at 1000° C. for 60 minutes, and then cooling to room temperature to obtain the burnt oyster shell powder.

[0045] A kind of preparation method of above-mentioned non-slip daily-use ceramics, comprises the following steps:

[0046] 1) Put kaolin into the ball mill, add KH791 silane coupling agent, and bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com