A kind of acid rain-resistant reflective heat-insulating black grid paint and preparation method thereof

An acid rain-resistant, gridded technology, applied in reflective/signal paints, latex paints, coatings, etc., can solve problems such as increased material loss and labor costs, increased cooling energy consumption, paint film damage, etc., and achieves good near-infrared reflection. performance, saving construction costs, and not easy to chalk and fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

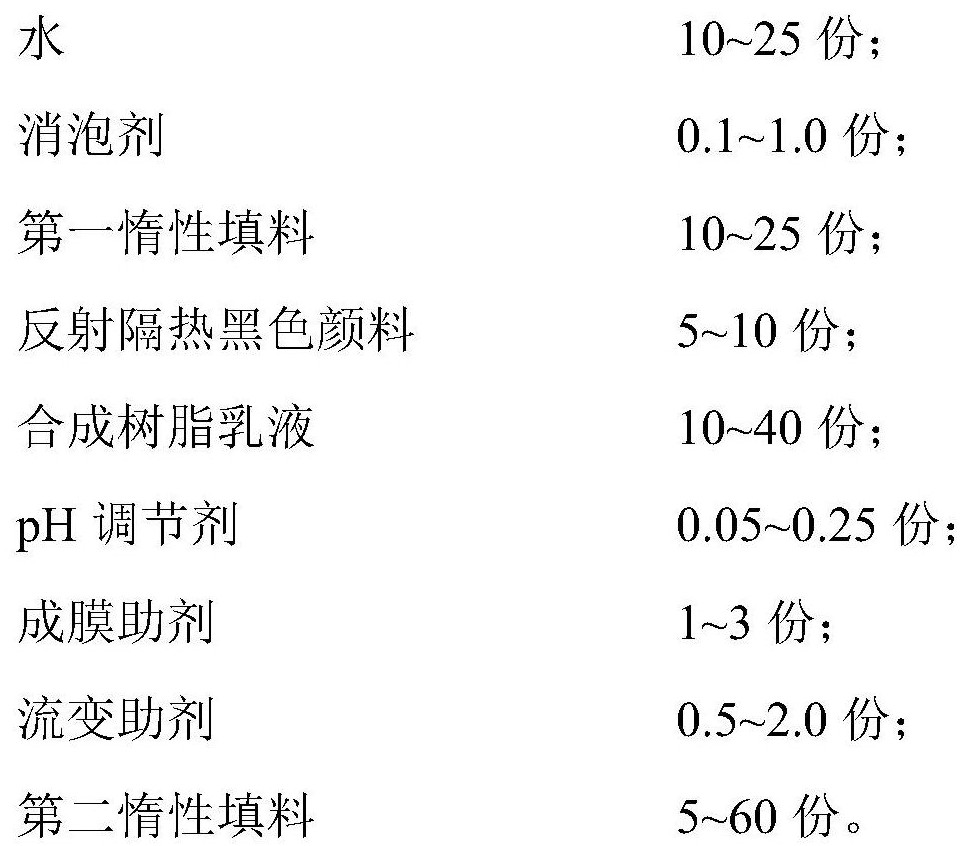

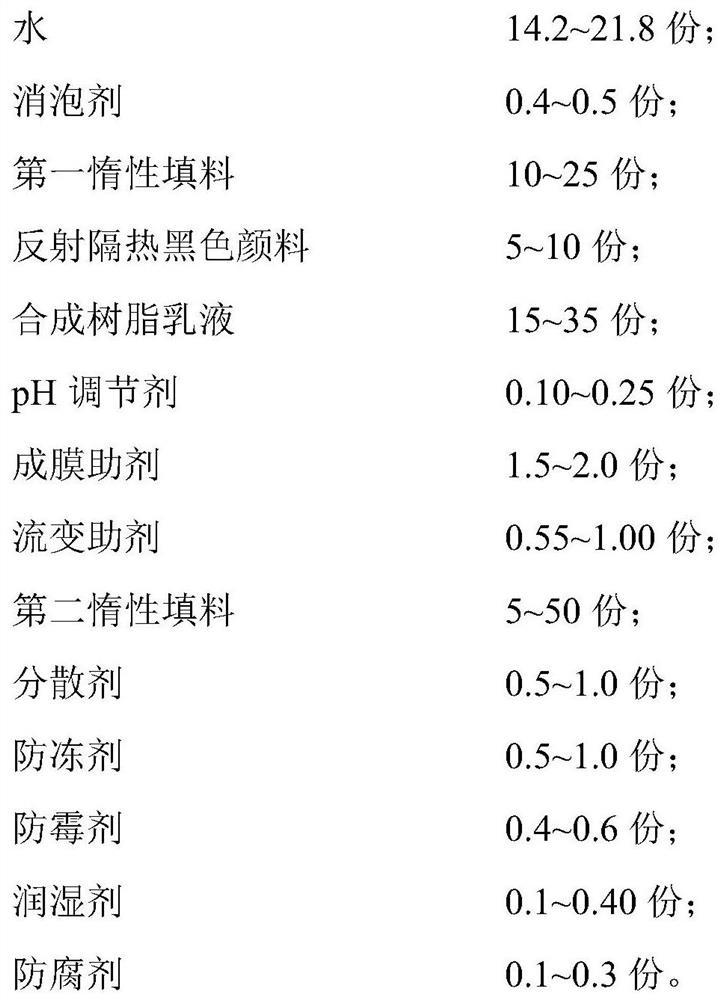

Method used

Image

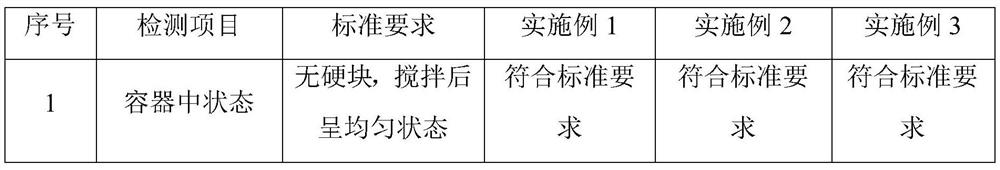

Examples

Embodiment 1

[0032] A kind of acid rain-resistant reflective heat-insulating black grid paint is a thin-coated latex paint, which is prepared by the following method:

[0033] Step 1: Weigh 21.8 parts of water, and put in antifreeze ethylene glycol: 0.5 parts, rheology additive 250HHBR: 0.15 parts, and pH regulator at a speed of 400-800 rpm BS 168: 0.25 parts, dispersant Orotan TM 731: 0.5 part, wetting agent ECOSURF TM LF-45: 0.1 part, defoamer ST 2410: 0.4 parts, dispersed for 5 minutes;

[0034] Step 2: Add barium sulfate: 20.0 parts, mica powder: 5 parts in turn at the speed of 800-1000 rpm, disperse for 15-25 minutes, and detect the fineness ≤ 60 microns; at 400-600 rpm Under the rotating speed, put in reflective and heat-insulating black pigment IR-801: 8.0 parts, disperse for 5 minutes and then put in synthetic resin emulsion CN18: 35.0 parts, dispersed for 5 minutes;

[0035] Step 3: Add preservatives in sequence at a speed of 300-500 rpm MV: 0.3 parts, antifungal agent ...

Embodiment 2

[0038] A kind of acid-rain-resistant reflective heat-insulating black grid paint is a glossy thick-coated latex paint, which is prepared by the following method:

[0039] Step 1: Weigh 14.65 parts of water, and add antifreeze propylene glycol: 0.5 parts, rheology additive EBS 481 FQ: 0.1 parts, pH regulator AMP 95: 0.15 parts, and disperse at a speed of 400 to 800 rpm. Agent Alcosperse747: 0.8 parts, wetting agent ECOSURF TM BD-405: 0.1 part, defoamer Dispelair CF 246: 0.5 part, disperse for 5 minutes;

[0040] Step 2: Add barium sulfate: 15.0 parts, mica powder: 2.5 parts, talcum powder: 2.5 parts in sequence at a speed of 800-1000 rpm, and disperse for 15-25 minutes, and the detection fineness is ≤ 60 microns; at 400 At ~600 rpm, put in reflective heat-insulating black pigment V-760: 10.0 parts, disperse for 5 minutes, then put in synthetic resin emulsion Primal TX-100: 20.0 parts, disperse for 5 minutes;

[0041] Step 3: Add the preservative PROXEL in sequence at a speed...

Embodiment 3

[0044] The acid-rain-resistant reflective heat-insulating black grid paint described in embodiment 3 is thick-coated latex paint on the rough surface, and is prepared by the following method:

[0045] Step 1: Weigh 14.2 parts of water, and put in antifreeze propylene glycol: 1.0 part, rheology additive HEC: 0.2 part, pH regulator ammonia water: 0.1 part, and dispersant at a speed of 400-800 rpm. CX 4320: 1.0 part, wetting agent Hydropalat WE 3475: 0.1 part, defoamer DF691: 0.4 part, disperse for 5 minutes;

[0046] Step 2: Add barium sulfate: 5.0 parts, mica powder: 5.0 parts sequentially at the speed of 800-1000 rpm, disperse for 15-25 minutes, and detect the fineness ≤ 60 microns; at 400-600 rpm Under the rotating speed, reflective and heat-insulating black pigment XFast 0095: 5.0 parts, disperse for 5 minutes, then add synthetic resin emulsion Carboset CA-600: 15.0 parts, disperse for 5 minutes;

[0047] The third step: at the speed of 300-500 rpm, put in the preservative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com