Single-crystal material and preparation method and application

A single crystal material and unit cell technology, which is applied in polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problem that the comprehensive performance cannot reach the ideal level of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The preparation of embodiment 1 sulfur-zinc-indium-barium single crystal

[0067] BaSe, In 2 Se 3 , ZnSe was weighed according to the molar ratio of 10:6:7, mixed evenly, pressed into tablets, put into a graphite crucible, then put into a quartz tube, sealed after vacuuming, placed in a high-temperature furnace, and heated at a rate of 100°C / h Raise the temperature to 920°C, keep the temperature constant for 50 hours, cool down to 900°C at a cooling rate of 0.8°C / h, and then cool down to room temperature naturally to obtain orange-red crystals with the chemical formula Ba 10 In 6 Zn 7 Se 26 , belongs to the orthorhombic crystal system, recorded as sample 1#.

[0068] BaS, In 2 Se 3 , ZnSe was weighed according to the molar ratio of 10:6:7, mixed evenly, pressed into tablets, put into a graphite crucible, then put into a quartz tube, sealed after vacuuming, placed in a high-temperature furnace, and heated at a rate of 50°C / h Raise the temperature to 850°C, keep t...

Embodiment 2

[0069] Example 2 Structural testing of barium selenium zinc indium barium and sulfur selenium zinc indium barium single crystal

[0070] The X-ray powder diffraction phase analysis (XRD) of the selenium zinc indium barium and sulfur selenium zinc indium barium single crystal prepared in embodiment 1 is carried out on the MiniFlex II type X-ray diffractometer of Rigaku company, Cu target, Kα radiation source (λ = 0.154184 nm). Test results such as Figure 4 Shown, where (a) is Ba 10 In 6 Zn 7 S 10 Se 16 Powder diagram, (b) diagram is Ba 10 In 6 Zn 7 Se 26 Powder chart. The results show that the samples 1# and 2# prepared in Example 1 are samples with high purity and high crystallinity. Both samples 1# and 2# are crystals, both belong to the orthorhombic crystal system, and the space group I-42m.

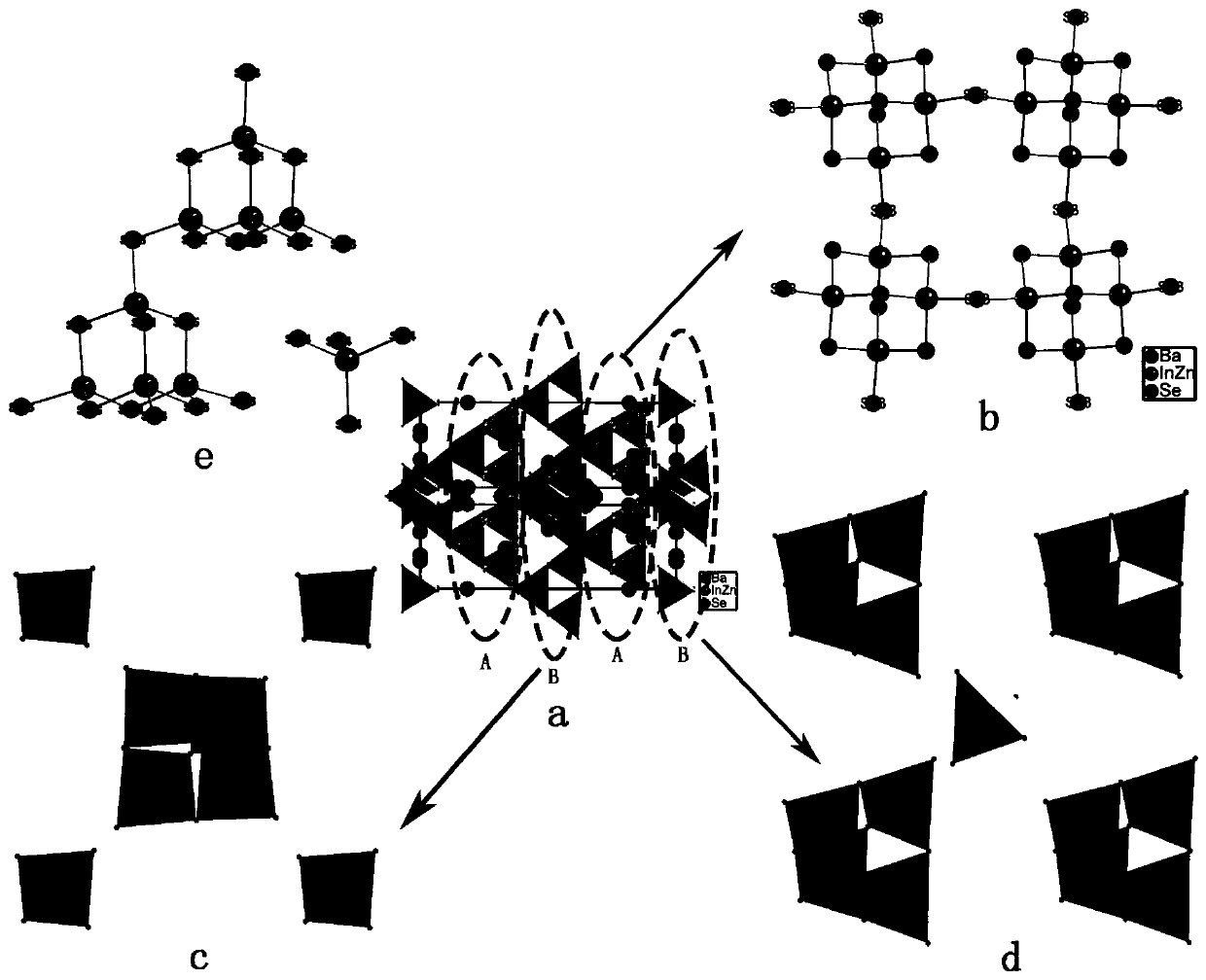

[0071] The X-ray single crystal diffraction of the zinc indium barium selenium and barium sulfur selenium zinc indium barium single crystal prepared in embodiment 1 is car...

Embodiment 3

[0072] Example 3 Performance Test of Barium Selenium Zinc Indium Barium and Sulfur Selenium Zinc Indium Barium Single Crystal

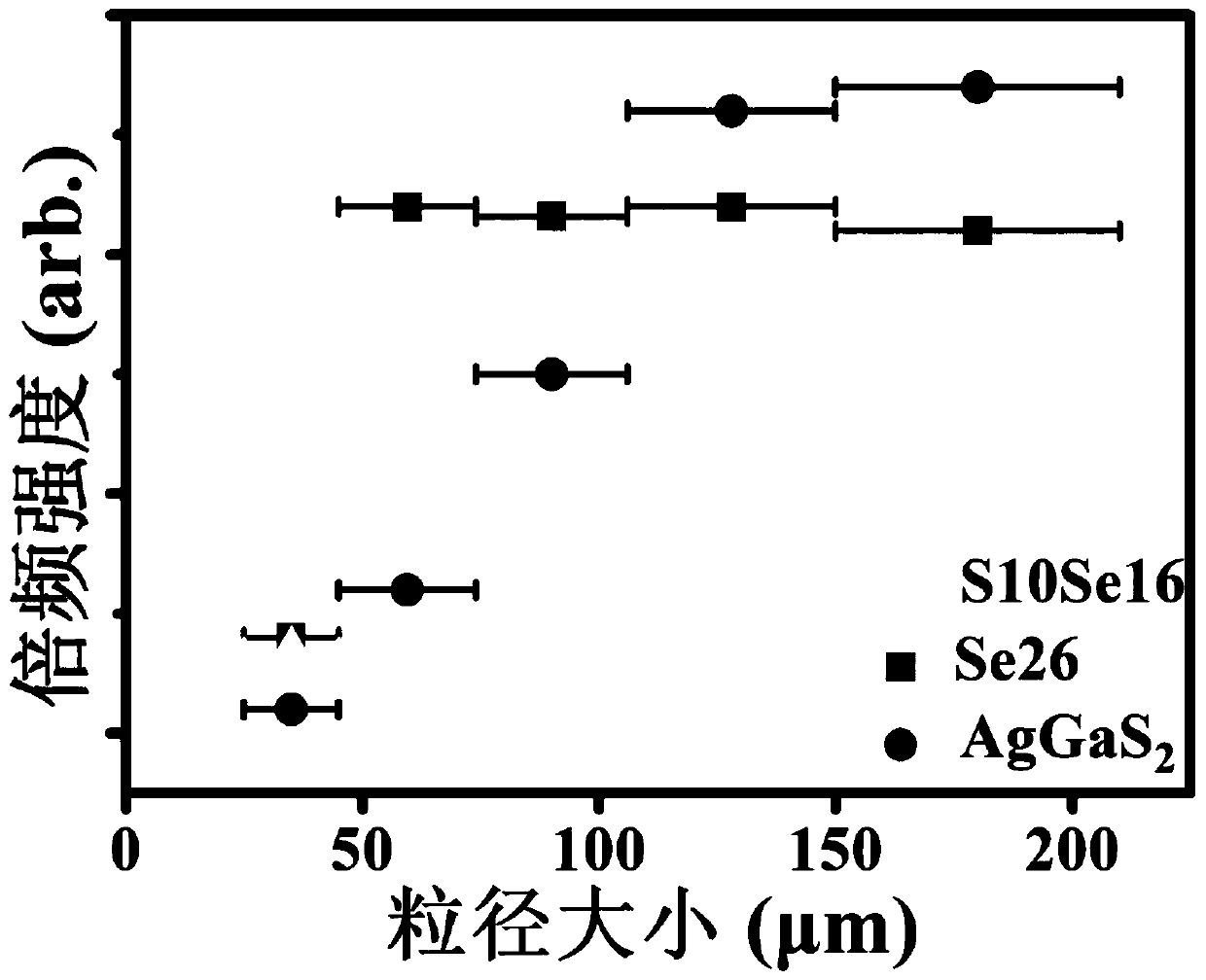

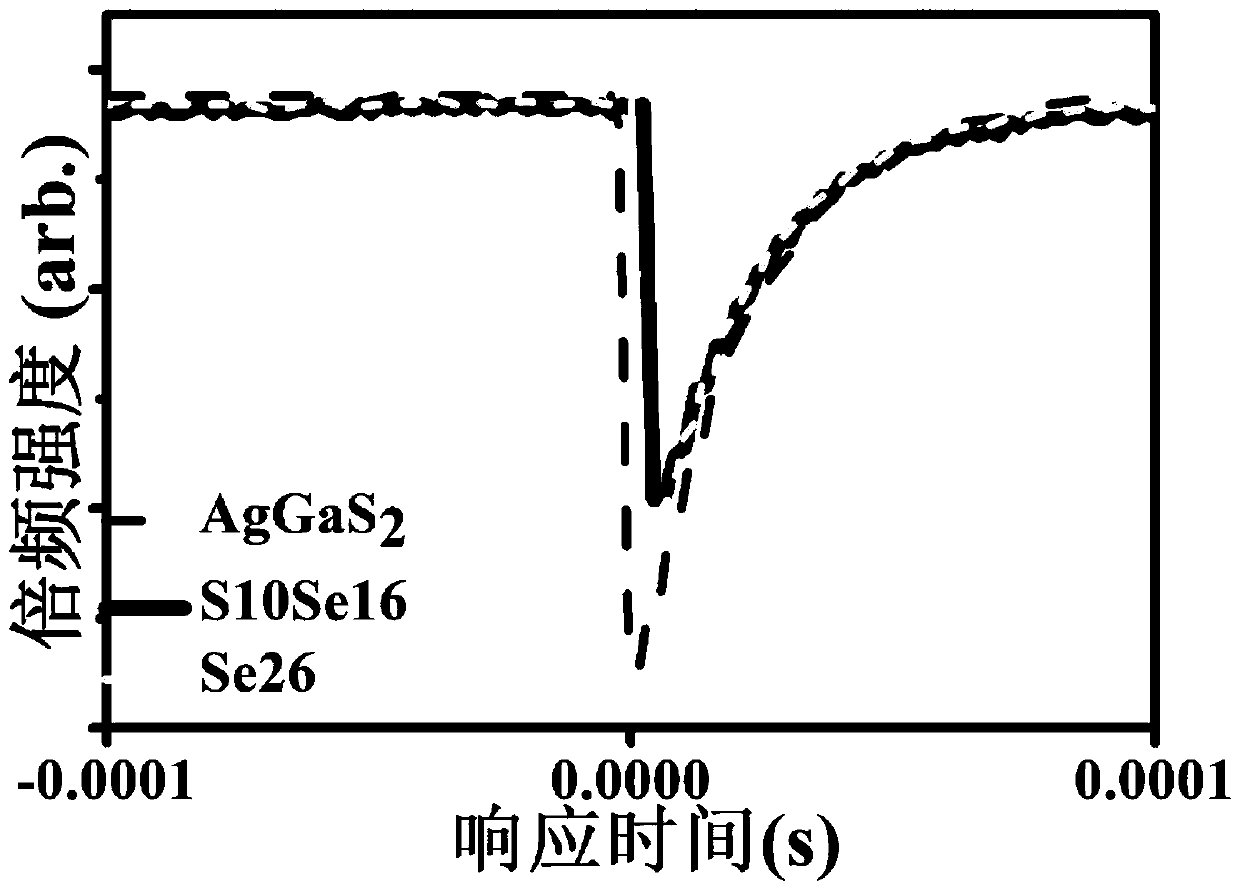

[0073] The sample to be tested and the standard sample AgGaS 2 Grind separately, and use a standard sieve to sieve crystal samples with a particle size of 25-44 μm, 44-74 μm, 74-106 μm, 106-150 μm, and 150-210 μm, place the sample between two glass sheets and compact it, and make the sample have 0.5mm thick, then put it into a cylindrical aluminum box with a diameter of 8mm. Powder frequency doubling tests were performed on samples 1# and 2# single crystals using a Q-switched 2.05 μm infrared laser. The specific steps of the frequency doubling experiment of samples 1# and 2# are as follows: place the sample between the optical path of the 2.05 μm laser emitter and the 1.025 μm laser detector, and display the obtained frequency doubling optical signal on the oscilloscope, And by comparing the voltage intensity displayed by the oscilloscope, the perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com