High-precision calibration device and method for thin film type heat flow meter

A technology of calibration device and heat flow meter, applied in the field of thermal measurement, can solve the problems of long operation time, complicated and expensive calibration device, difficult experimental operation, etc., and achieve the effects of simple and convenient operation, one-dimensional heat conduction, and short relaxation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention is further described:

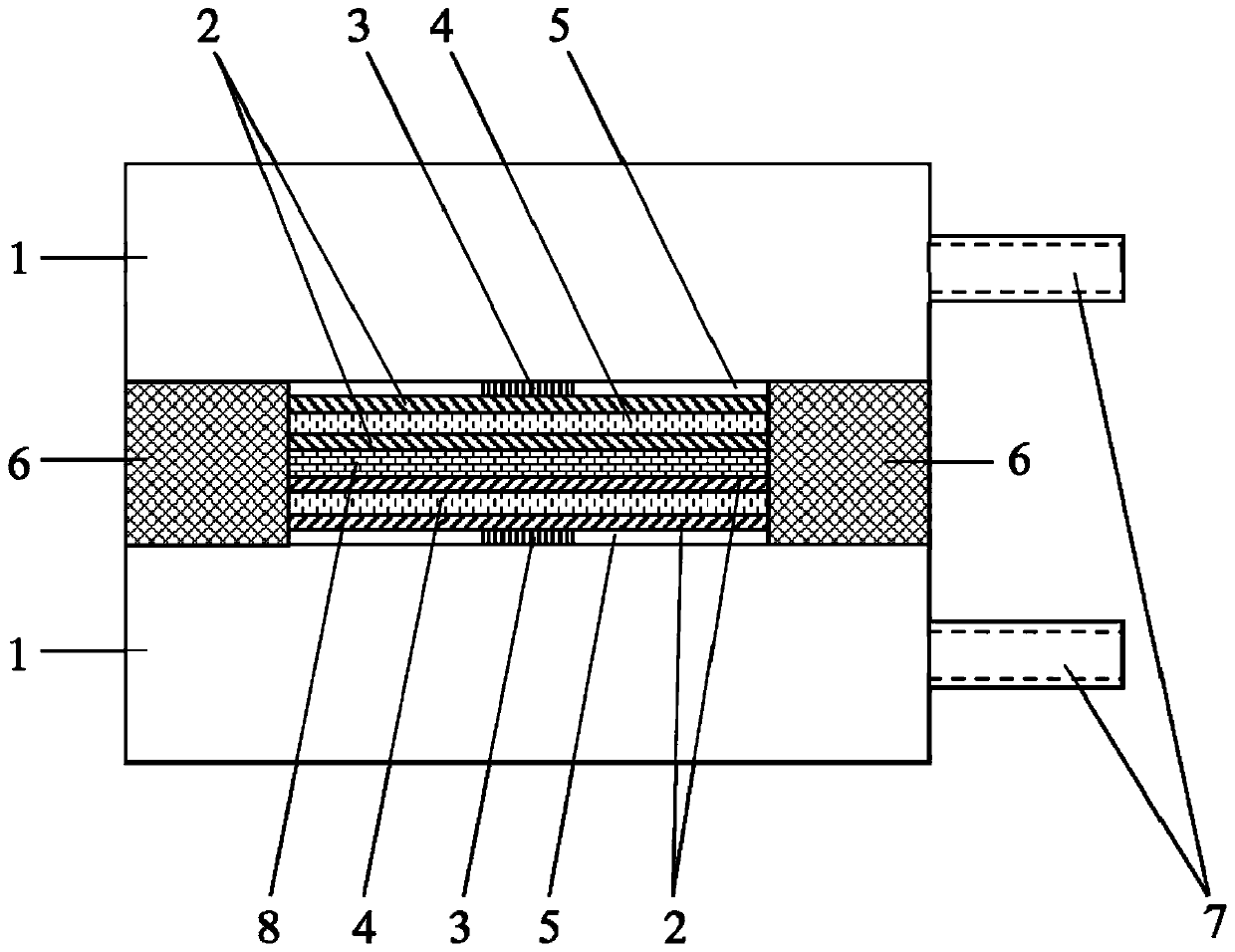

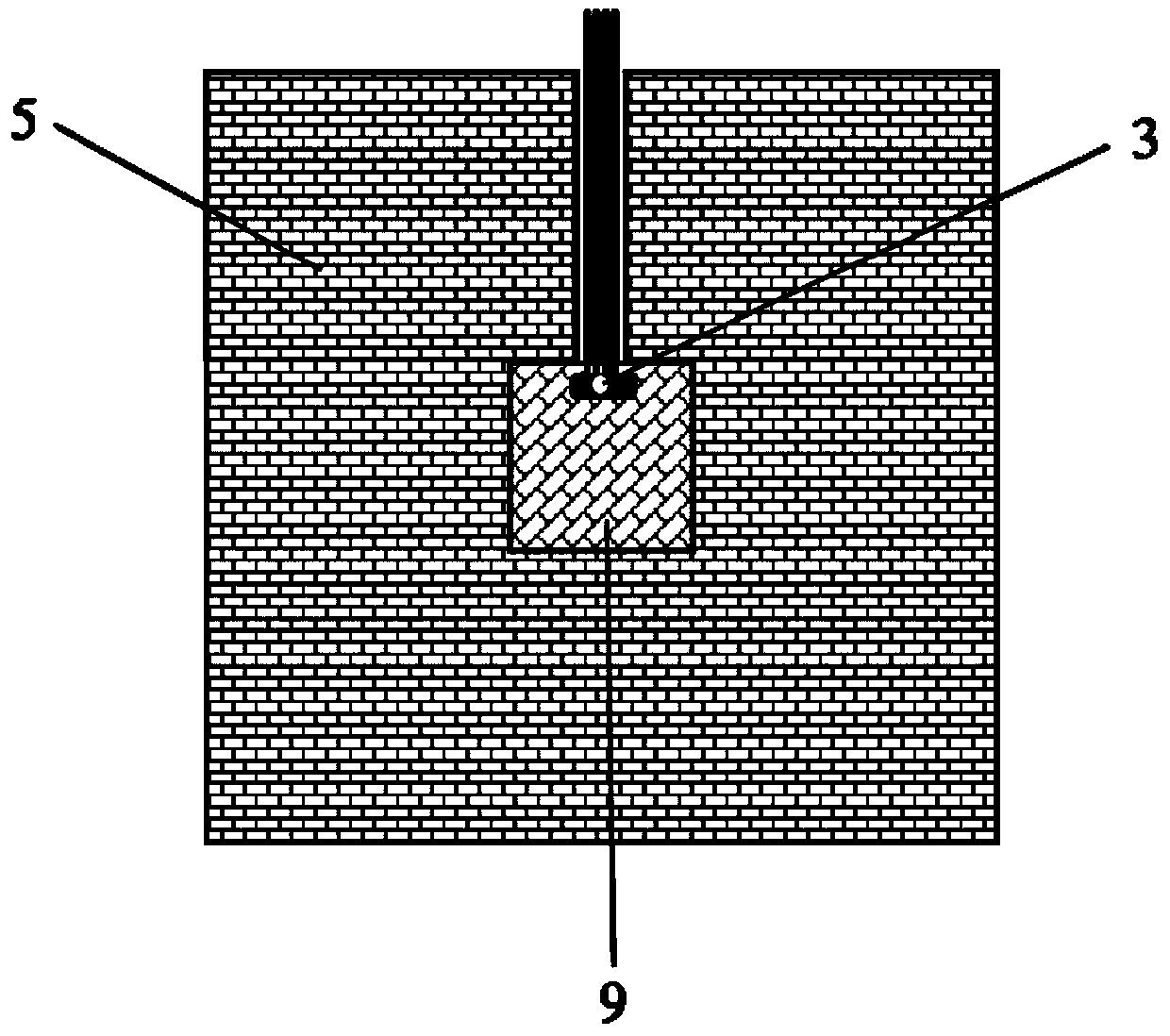

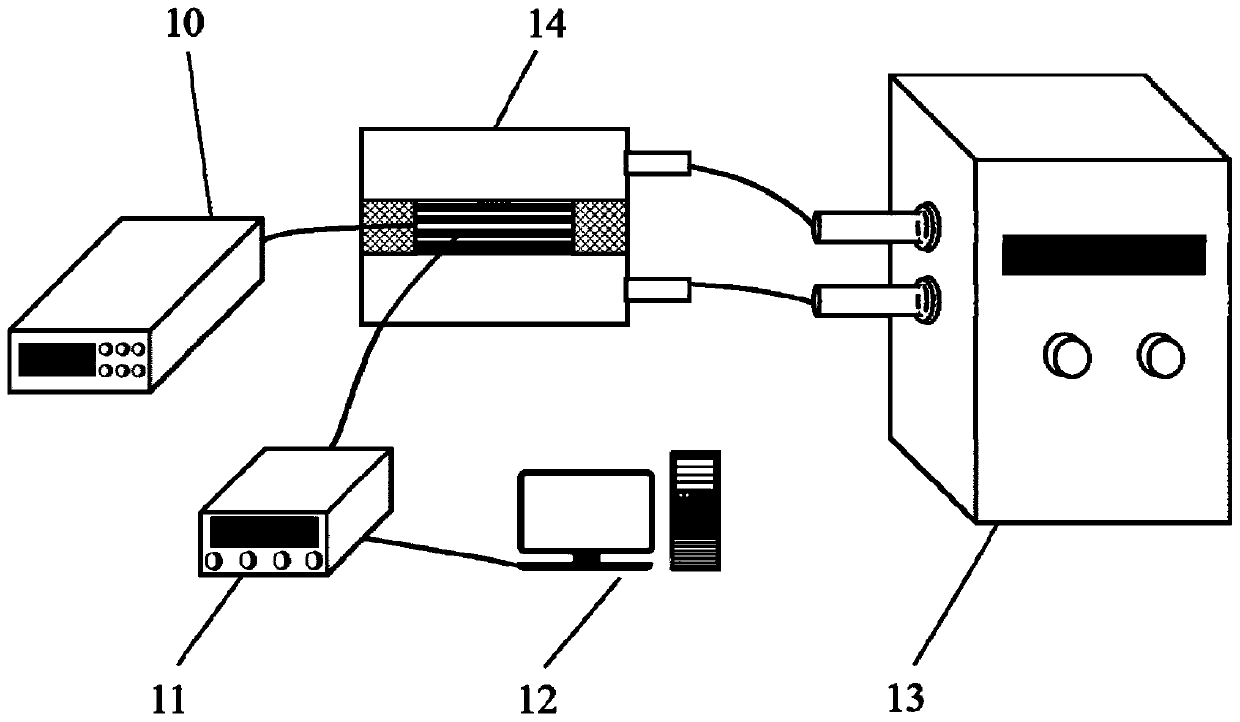

[0038] Such as Figure 1 to Figure 3 As shown, a high-precision calibration device for a thin-film heat flow meter provided by the present invention includes a heating system, a cooling system, a data acquisition system and a calibration experiment device 14; wherein, the heating system includes a polyimide electric heating film 8 and a direct current Stabilized power supply 10; the cooling system includes a constant temperature water chamber and a temperature-adjustable cooling water cycle machine 13; the data acquisition system includes a Keithley multi-channel data collector 11 and a computer 12; Meter 3, mica sheet 4, polyimide film 5, high thermal conductivity aluminum foil 2, thermal insulation cotton 6 and the K-type thermocouple 9 of the heat flow meter itself; during work, the polyimide electric heating film 8 is set in two constant temperature water In the center of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com