A kind of copper-doped phosphomolybdic acid low-temperature denitrification catalyst and preparation method thereof

A technology of low-temperature denitrification and phosphomolybdic acid, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as poor ability, achieve the effect of increasing exposure, expanding application, and improving low-temperature denitrification activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

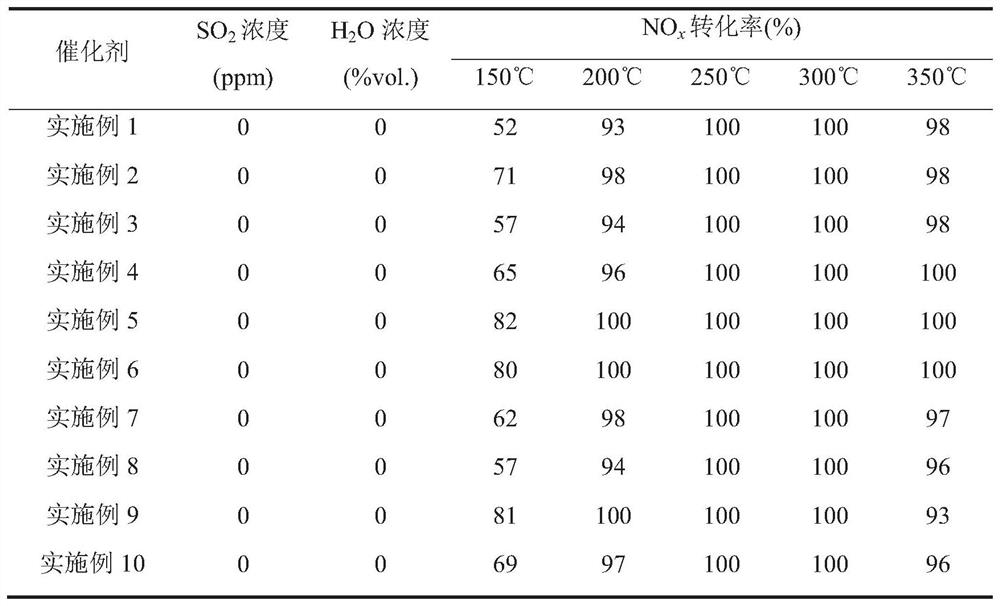

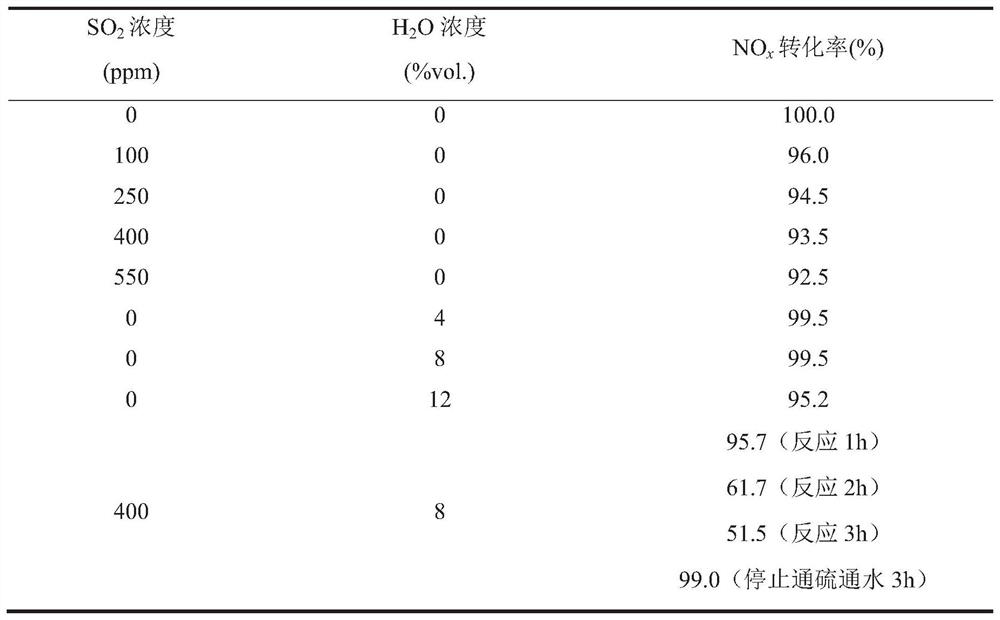

Examples

Embodiment 1

[0060] Step 1: Preparation of Active Components

[0061] The first step, weigh 1g of phosphomolybdic acid, 0.005g of PEG (weighed according to 0.5% of the mass of phosphomolybdic acid) and 2g of copper nitrate (control the molar ratio of Cu and Mo to be 2:1) into a crucible, add 40ml of distilled water to dissolve , stirring at a constant speed on a magnetic stirrer for 1 hour, and controlling the stirring temperature to 25°C; the second step, drying the mixture in the first step on a magnetic stirrer at a constant speed, evaporating the water to dryness, and controlling the drying temperature to 85°C; The third step is to place the mixture in the second step into a drying oven for constant temperature drying, and the drying temperature is controlled to be 105°C; the fourth step is to put the mixture dried in the third step into a muffle furnace for calcination at 350°C for 3 hours, The active ingredient is obtained after cooling.

[0062] Step 2: Preparation of Catalyst

[...

Embodiment 2

[0065] Step 1: Preparation of Active Components

[0066] The first step, weigh 1g of phosphomolybdic acid, 0.005g of PEG (weighed by 0.5% of the mass of phosphomolybdic acid) and 4.7658g of copper nitrate (control the molar ratio of Cu and Mo to be 3:1) into the crucible, add 40ml of distilled water Dissolve, stir on a magnetic stirrer at a constant speed for 1 hour, and control the stirring temperature to 25°C; in the second step, dry the mixture in the first step on a magnetic stirrer at a constant speed, evaporate the water to dryness, and control the drying temperature to 85°C; In the third step, put the mixture in the second step into a drying oven to dry at a constant temperature, and control the drying temperature to 105°C; in the fourth step, put the dried mixture in the third step into a muffle furnace for calcination at 350°C for 3 hours , to obtain the active ingredient after cooling.

[0067] Step 2: Preparation of Catalyst

[0068] In the first step, weigh 0.3g ac...

Embodiment 3

[0070] Step 1: Preparation of Active Components

[0071] The first step, weigh 1g of phosphomolybdic acid, 0.005g PEG (weighed according to 0.5% of the mass of phosphomolybdic acid) and a certain amount of copper nitrate (control the molar ratio of Cu and Mo to be 4:1) and put them into the crucible, add 40ml of distilled water Dissolve, stir on a magnetic stirrer at a constant speed for 1 hour, and control the stirring temperature to 25°C; in the second step, dry the mixture in the first step on a magnetic stirrer at a constant speed, evaporate the water to dryness, and control the drying temperature to 85°C; In the third step, put the mixture in the second step into a drying oven to dry at a constant temperature, and control the drying temperature to 105°C; in the fourth step, put the dried mixture in the third step into a muffle furnace for calcination at 350°C for 3 hours , to obtain the active ingredient after cooling.

[0072] Step 2: Preparation of Catalyst

[0073] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com