SAPO-34 molecular sieve aggregate, preparation method thereof and method for preparing olefin from methanol

A SAPO-34 molecular technology, applied in molecular sieves and alkali exchange phosphates, molecular sieve catalysts, molecular sieve characteristic silicoaluminophosphates, etc., can solve problems such as carbon deposition, reduce molecular sieve production costs, and low selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The first aspect of the present invention provides a kind of preparation method of SAPO-34 molecular sieve aggregate, comprising:

[0028] (1) The solution obtained by mixing aluminum source, phosphorus source, silicon source, triethylamine, triethylamine hydrochloride and water is subjected to hydrothermal crystallization; wherein,

[0029] In the solution, the aluminum source is Al 2 o 3 Calculated, phosphorus source as P 2 o 5 meter, silicon source as SiO 2 Calculated, the mol ratio of described aluminum source, phosphorus source, silicon source, triethylamine, triethylamine hydrochloride and water is:

[0030] Al 2 o 3 :P 2 o 5 : SiO 2 : Triethylamine: Triethylamine hydrochloride: H 2 O=1: (0.9~1.1): (0.1~0.5): (1.5~3): (0.1~0.5): (15~50);

[0031] (2) Separating the product obtained by hydrothermal crystallization in step (1) from solid to liquid, washing, drying and roasting the obtained solid to obtain the SAPO-34 molecular sieve aggregate.

[0032] I...

Embodiment 1

[0054] Pseudoboehmite, phosphoric acid, silica sol, triethylamine, triethylamine hydrochloride and deionized water were added to the reaction kettle, stirred at room temperature (25°C) at a stirring rate of 500rpm for 4h, and the above-mentioned components in the obtained solution The molar ratio of the components is Al 2 o 3 :P 2 o 5 : SiO 2 : Triethylamine: Triethylamine hydrochloride: H 2 O=1:1.0:0.25:1.5:0.5:20.

[0055] Hydrothermal crystallization was carried out at the temperature of the reactor, and the crystallization was carried out at a temperature of 200° C. and a pressure of 2 MPa for 24 hours.

[0056] The product after crystallization was separated by filtration, and the obtained solid was washed with deionized water. Dry at 120°C for 2 hours, and bake at 550°C for 3 hours to obtain SAPO-34 molecular sieve aggregates.

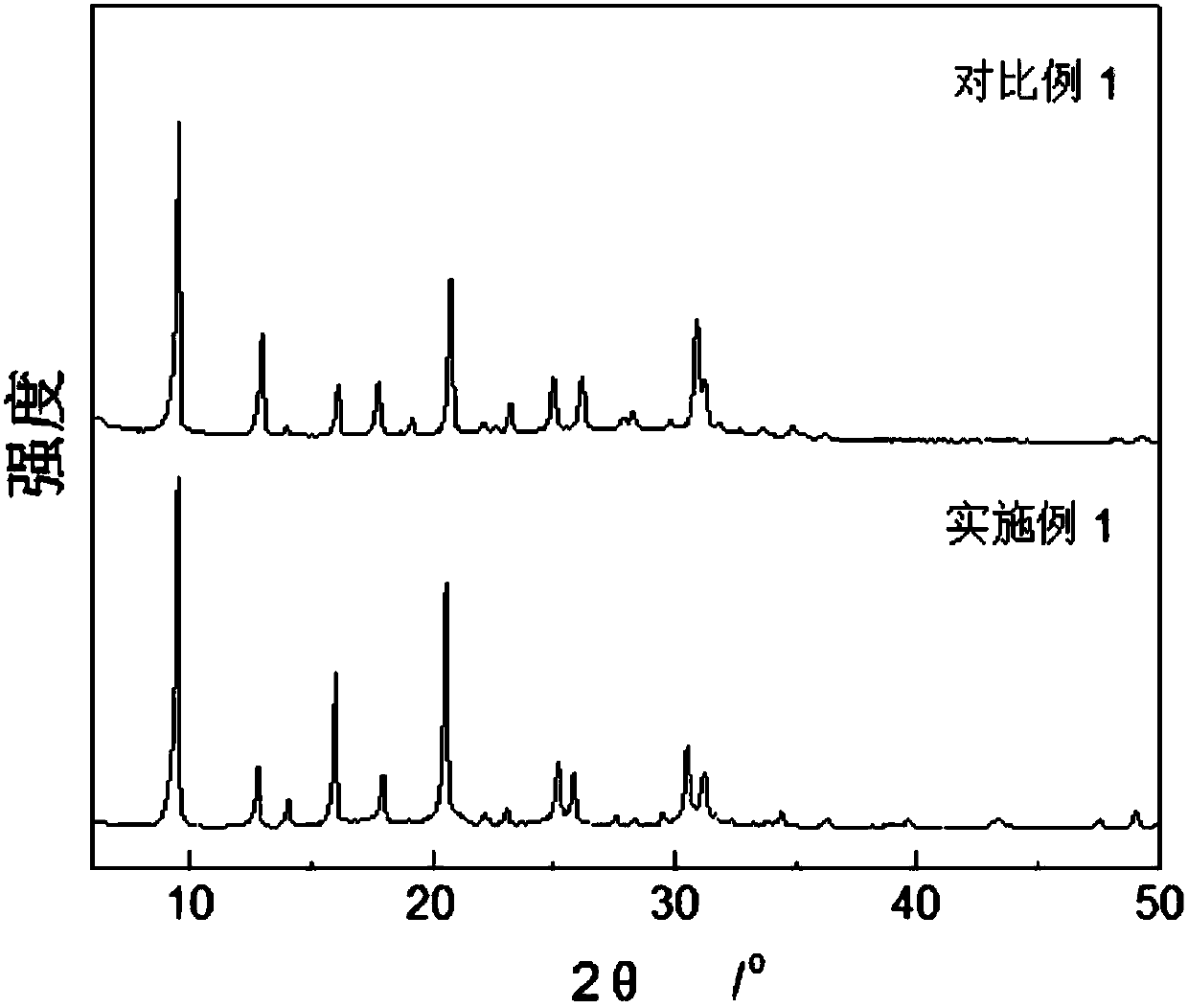

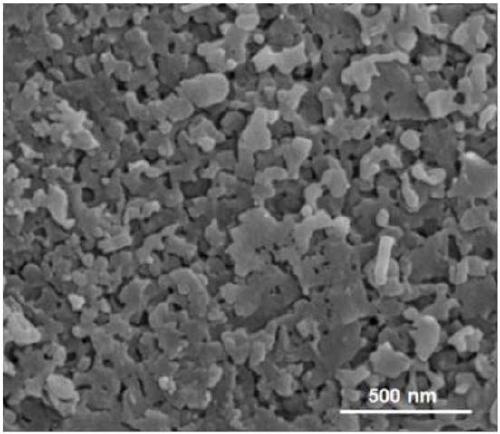

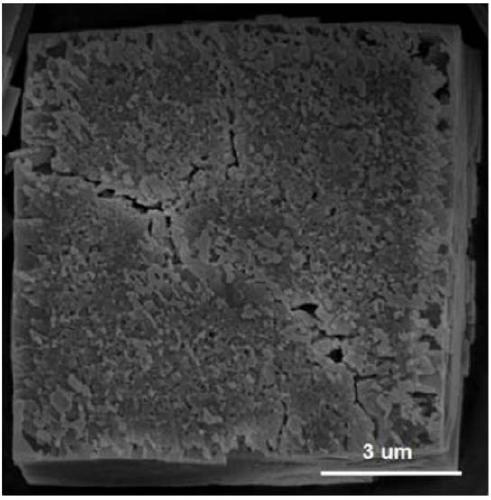

[0057] The SAPO-34 molecular sieve aggregates were analyzed by XRD spectrum, figure 1 The obtained XRD pattern shows SAPO-34 crystals. ...

Embodiment 2

[0061] Pseudoboehmite, phosphoric acid, silica sol, triethylamine, triethylamine hydrochloride and deionized water were added to the reaction kettle, stirred at room temperature (40°C) at a stirring rate of 100rpm for 3h, and the above-mentioned components in the obtained solution The molar ratio of the components is Al 2 o 3 :P 2 o 5 : SiO 2 : Triethylamine: Triethylamine hydrochloride: H 2 O=1:0.9:0.12:2.0:0.4:50.

[0062] Hydrothermal crystallization was carried out at the temperature of the reactor, and the crystallization was carried out at a temperature of 190° C. and a pressure of 3 MPa for 12 hours.

[0063] The product after crystallization was separated by filtration, and the obtained solid was washed with deionized water. Dry at 100°C for 1.5h, and bake at 500°C for 5h to obtain SAPO-34 molecular sieve aggregates.

[0064] The XRD spectrum analysis of the SAPO-34 molecular sieve aggregates showed that they were SAPO-34 crystals.

[0065] The SAPO-34 molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rib length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com