Preparation method of cerium-stabilized zirconia-toughened alumina ceramic material

A technology for stabilizing zirconia and alumina ceramics, applied in the field of ceramic material preparation, can solve the problems of shortening the experiment time and time-consuming precipitation and washing, and achieve the effect of shortening the experiment time, shortening the preparation cycle and ensuring the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

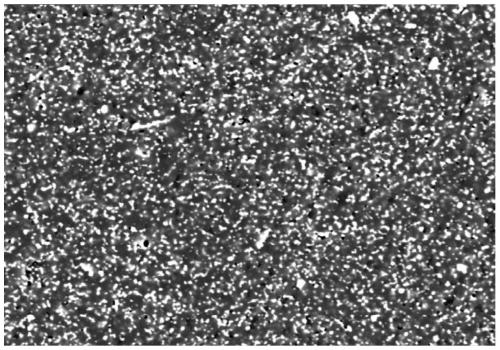

Embodiment 1

[0038] (1) Use zirconium oxychloride octahydrate and cerium nitrate hexahydrate as raw materials to prepare a solution by adding deionized water respectively, and mix and stir for 1 hour to obtain a mixed solution. Ce in the mixed solution 3+ and Zr 4+ The molar ratio of the solution is 4:96, and the concentration of 0.1mol / L ammonia water is added dropwise.

[0039] (2) After flocculent precipitation occurs in the solution, add polyethylene glycol with a quality of 3% of the total mass of zirconium oxychloride octahydrate and cerium nitrate hexahydrate, and continue stirring until the pH of the solution is adjusted to 9.5-10.5. Precipitation is complete.

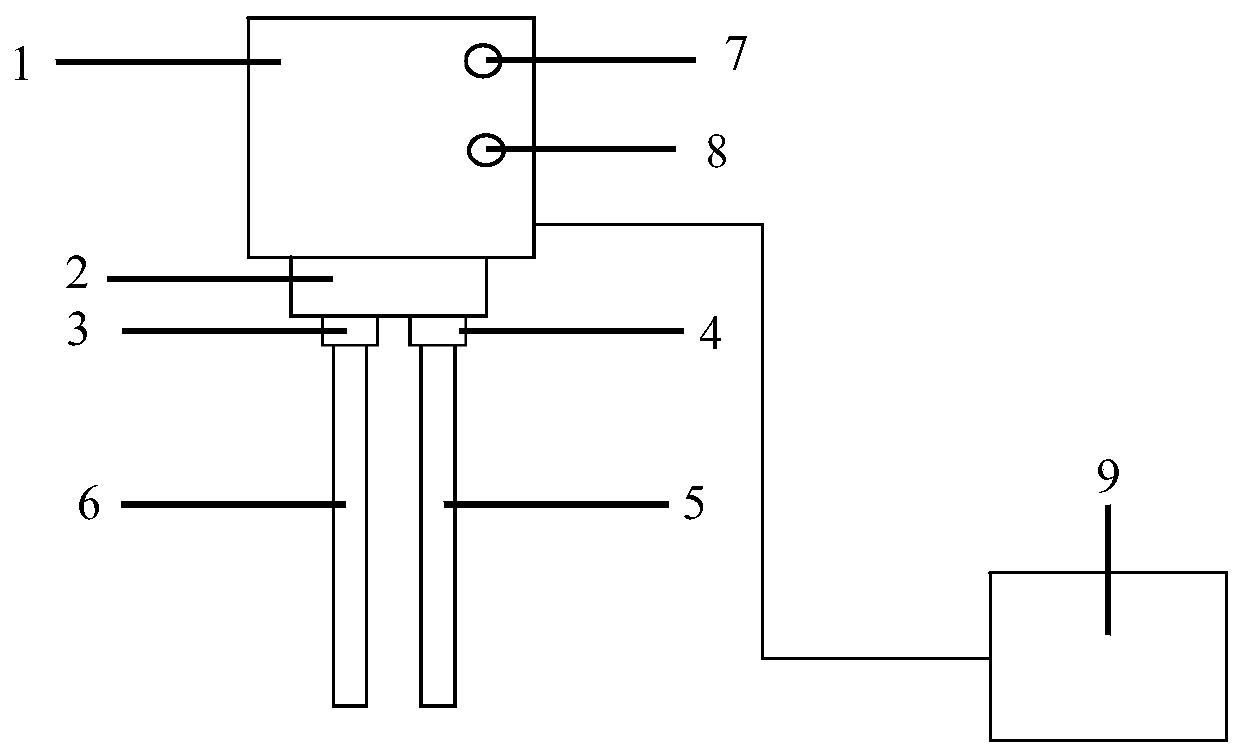

[0040] (3) The improved electric adsorption device is fixed on the top of the container containing the precipitation mixed solution, the motor switch 7 is turned on, and the negative electrode plate 5 and the positive electrode plate 6 fixed on the bottom of the turntable 2 rotate with the turntable 2 to stir the precipita...

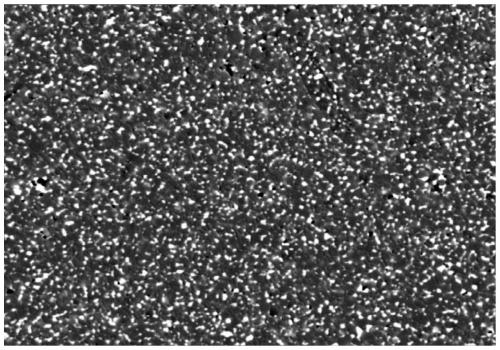

Embodiment 2

[0049] (1) Use zirconium oxychloride octahydrate and cerium nitrate hexahydrate as raw materials to prepare a solution by adding deionized water respectively, and mix and stir for 1 hour to obtain a mixed solution. Ce in the mixed solution 3+ and Zr 4+ The molar ratio of the solution is 14:86, and the concentration of 0.1mol / L ammonia water is added dropwise.

[0050] (2) After flocculent precipitation occurs in the solution, add ammonium polyacrylate with a quality of 3% of the total mass of zirconium oxychloride octahydrate and cerium nitrate hexahydrate raw material, continue stirring until the pH of the solution is adjusted to 9.5-10.5, and the solution precipitates completely.

[0051] (3) The improved electric adsorption device is fixed on the top of the container containing the precipitation mixed solution, the motor switch 7 is turned on, and the negative electrode plate 5 and the positive electrode plate 6 fixed on the bottom of the turntable 2 rotate with the turnta...

Embodiment 3

[0060] (1) Use zirconium oxychloride octahydrate and cerium nitrate hexahydrate as raw materials to prepare a solution by adding deionized water respectively, and mix and stir for 1 hour to obtain a mixed solution. Ce in the mixed solution 3+ and Zr 4+ The molar ratio of the solution is 8:92, and the concentration of 0.1mol / L ammonia water is added dropwise.

[0061] (2) After flocculent precipitation occurs in the solution, add ammonium polyacrylate with a quality of 3% of the total mass of zirconium oxychloride octahydrate and cerium nitrate hexahydrate raw material, continue stirring until the pH of the solution is adjusted to 9.5-10.5, and the solution precipitates completely.

[0062] (3) The improved electric adsorption device is fixed on the top of the container containing the precipitation mixed solution, the motor switch 7 is turned on, and the negative electrode plate 5 and the positive electrode plate 6 fixed on the bottom of the turntable 2 rotate with the turntab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com