Preparing method and application of heterogeneous catalyst for olefin polymerization

A technology of heterogeneous catalysts and polyolefin catalysts, which is applied in the field of preparation of heterogeneous catalysts for olefin polymerization, can solve problems affecting the subsequent processing of materials, and achieve the effects of large particle size, high bulk density, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

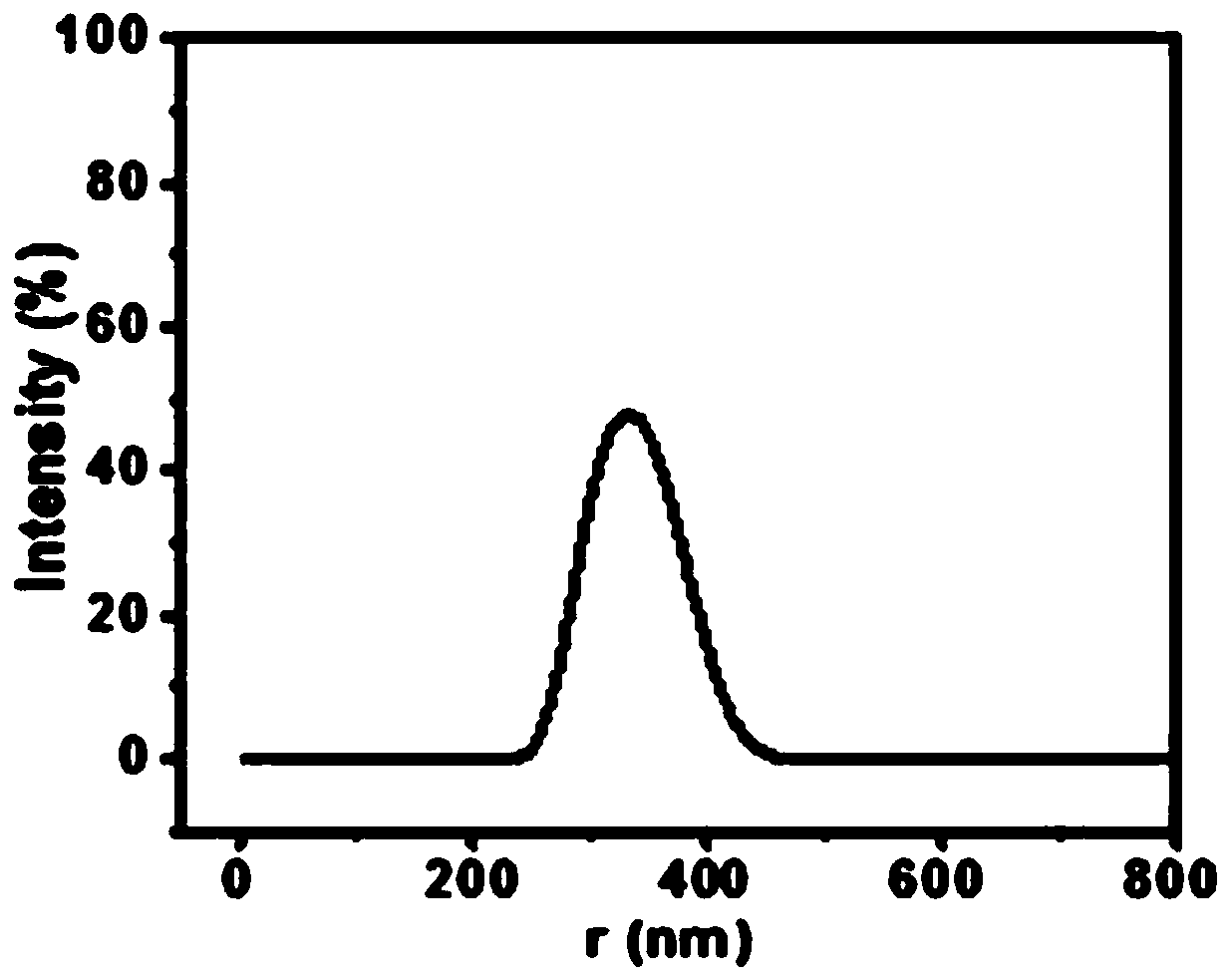

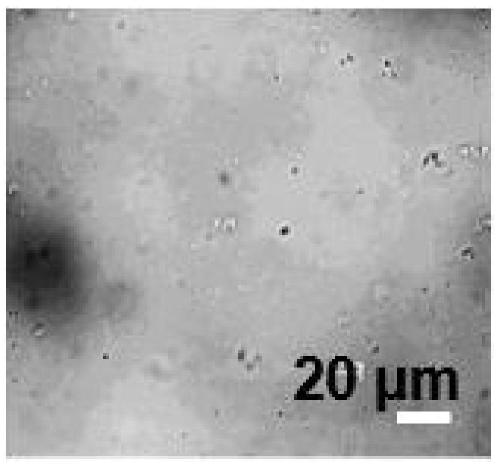

[0024] The reaction device was purged with high-purity nitrogen to remove air and water in the reaction device. 900 μmol of polyolefin catalyst TiCl 4 (Ziegler-Natta catalyst) was dissolved in 10 mL of solvent n-heptane, added 10 μmol of additive polysilsesquioxane, and stirred for 1 h, so that the polyolefin catalyst was agglomerated into particles in n-heptane, and a heterogeneous catalyst was prepared solvent. After the heterogeneous catalyst solution is monitored by laser particle size, it is measured that the particle size of the formed particles is 375nm, such as figure 1 shown. Optical microscope pictures of heterogeneous catalyst solutions such as figure 2 shown. Adjust the temperature of the slurry polymerization reactor to 60 °C, add 400 mL of polymerization solvent n-heptane, add 1 mL of the above-mentioned heterogeneous catalyst solution, stir for 10 min, and then add 90 μmol of cocatalyst triethylaluminum (the ratio of cocatalyst and heterogeneous catalyst M...

Embodiment 2

[0026] The reaction device was purged with high-purity nitrogen to remove air and water in the reaction device. 500 μmol of polyolefin catalyst TiCl 3 (Ziegler-Natta catalyst) was dissolved in 10 mL of solvent tetrahydrofuran, and 50 μmol of auxiliary agent diethyl ether (of course, other ethers such as dimethyl ether, silicon ether, and amino ether can also be used as nucleating agents) was stirred for 1 h to make the polyolefin catalyst The tetrahydrofuran is agglomerated into granules, and the heterogeneous catalyst solvent is obtained. After the heterogeneous catalyst solution is monitored by laser particle size, it is measured that the particle size of the formed particles is 50nm. Adjust the temperature of the slurry polymerization reactor to 120 ° C, add 400 mL of polymerization solvent toluene, add 1 mL of the above-mentioned heterogeneous catalyst solution, stir for 1 min, and then add 250 μmol of co-catalyst n-butyllithium (the molar ratio of co-catalyst to heteroge...

Embodiment 3

[0028] The reaction device was purged with high-purity nitrogen to remove air and water in the reaction device. 50mmol of polyolefin catalyst VCl 4 (Ziegler-Natta catalyst) was dissolved in 10 mL of solvent chloroform, and 50 mol of auxiliary agent ethyl acetate was added (of course, other esters such as methyl formate, acrylate, and fatty acid esters could also be used as nucleating agents), and stirred for 1 h to make the poly The olefin catalyst is agglomerated into particles in chloroform to obtain a heterogeneous catalyst solvent. After the heterogeneous catalyst solution is monitored by laser particle size, it is measured that the particle size of the formed particles is 900nm. Adjust the temperature of the slurry polymerization reactor to 0°C, add 400 mL of polymerization solvent n-hexane, add 1 mL of the above-mentioned heterogeneous catalyst solution, stir for 1 min, then add 5 mmol of cocatalyst diethylaluminum chloride (cocatalyst and heterogeneous catalyst The mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com