Application of MXene membrane in reverse electrodialysis power generation

A reverse electrodialysis and electrode technology, which is applied in the application field of MXene membrane in reverse electrodialysis power generation, can solve the problems of large film thickness and output power influence, and achieve long working life, stable potential and good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

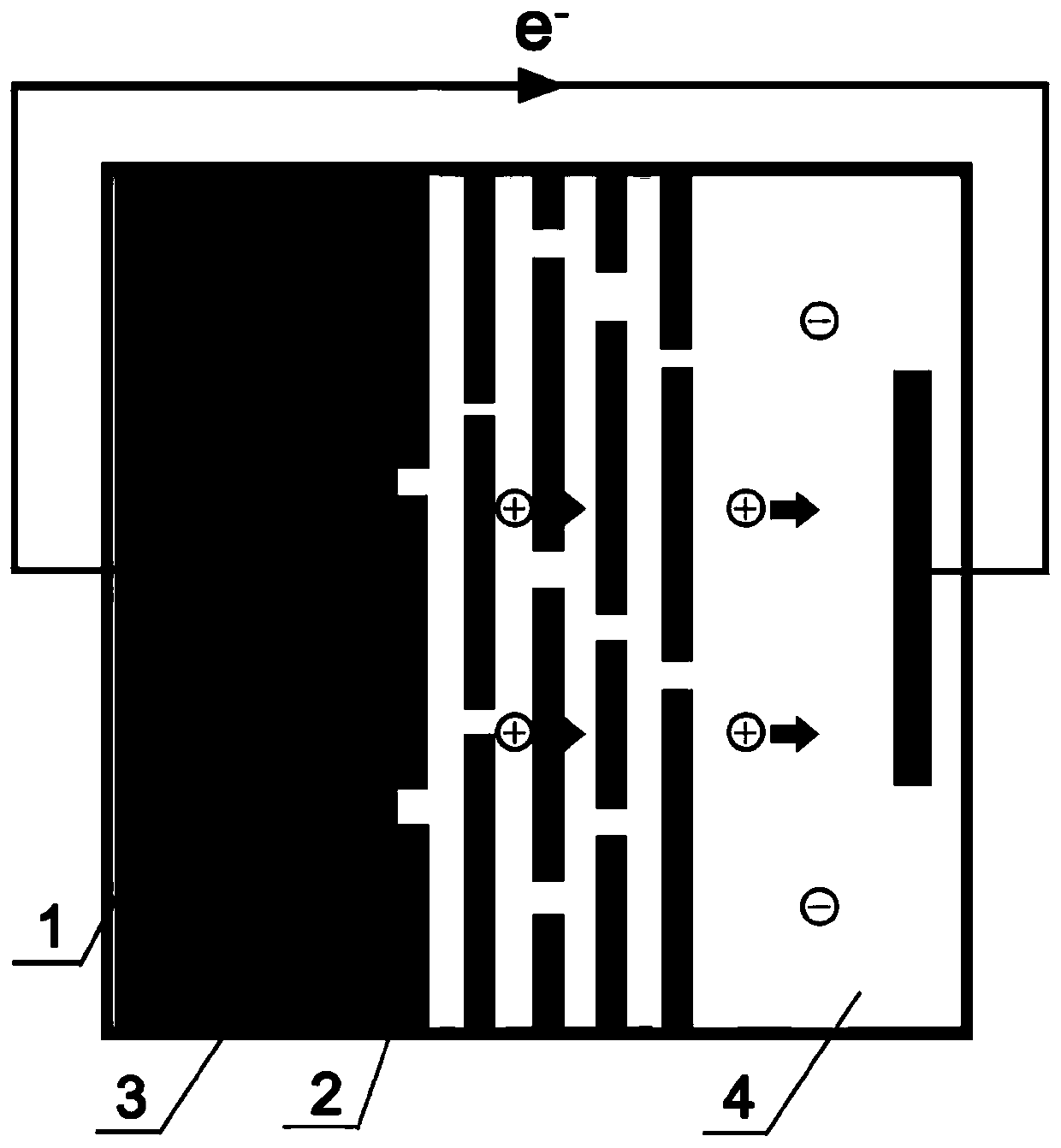

[0045] figure 2 It is a schematic diagram of the application of MXene membrane in reverse electrodialysis power generation. The device is mainly composed of electrode 1, two-dimensional layered MXene membrane 2, concentrated salt solution 3, and dilute salt solution 4. The saline solution is sodium chloride solution.

[0046] The ion-exchange MXene membrane in this device is Ti 3 C 2 T x The MXene film has a thickness of 5 μm, a layer spacing of 0.26 nm, and a single layer thickness of 1.5 nm, such as figure 1 As shown; the electrode is a silver / silver chloride electrode with a thickness of 200 μm; the molar concentration ratio of concentrated sodium chloride solution 3 and dilute sodium chloride solution 4 is 50:1, and the concentration of concentrated sodium chloride solution is 0.5mol / L , the pH is 5.85, the concentration of the dilute sodium chloride solution is 0.01mol / L, and the pH is 6.34.

[0047] Power generation process: the two-dimensional layered MXene membr...

Embodiment 2

[0050] Generating device and generating process are exactly the same as embodiment 1, just changed the following parameters in the generating device:

[0051] The ion-exchange MXene membrane in this device is Ti 3 C 2 T x MXene film, its thickness is 20 μm, the distance between MXene film layers is 0.3nm, and the thickness of single layer is 1.5nm; the electrode is a sheet-like silver / silver chloride electrode with a thickness of 400μm; concentrated sodium chloride solution and dilute sodium chloride solution The molar concentration ratio is 10:1, the concentration of the concentrated potassium chloride solution is 1mol / L, and the pH is 10.79, the concentration of the dilute potassium chloride solution is 0.1mol / L, and the pH is 3.77.

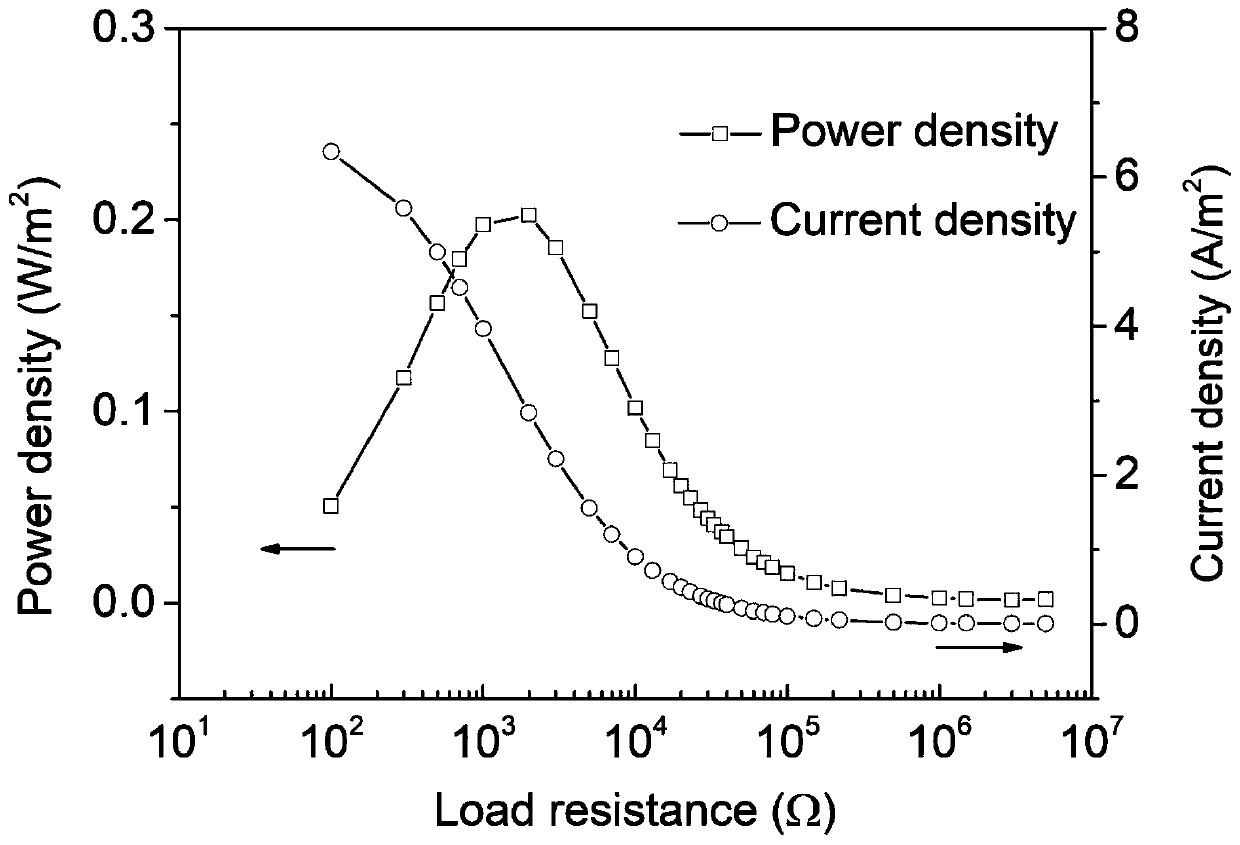

[0052] The results show that when the external resistance is 1000Ω, the output power of the power generation device is 0.65W / m 2 .

Embodiment 3

[0054] Generating device and generating process are exactly the same as embodiment 1, just changed the following parameters in the generating device:

[0055] The ion-exchange MXene membrane in this device is Ti 3 C 2 T x MXene film with a thickness of 30 μm, MXene film interlayer spacing of 0.35 nm, and a single layer thickness of 1.5 nm; the electrode is a sheet-shaped silver / silver chloride electrode with a thickness of 600 μm; concentrated sodium chloride solution and dilute sodium chloride solution The molar concentration ratio is 5:1, the concentration of concentrated sodium chloride solution is 0.5mol / L, the pH is 3.3, the concentration of dilute sodium chloride solution is 0.01mol / L, and the pH is 11.2.

[0056] The results show that when the external resistance is 3000Ω, the output power of the power generation device is 0.25W / m 2 , and the current remains stable within 3600s, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com