A kind of copper hydroxy bromide nano sheet and preparation method thereof

A technology of copper hydroxybromide and nanosheets, which is applied in the direction of copper halide and nanotechnology, and can solve problems such as unstable chemical properties and complex synthetic reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] High-purity copper nitrate dihydrate solid particles, hexamethylenetetramine particles, and potassium bromide particles are used as raw materials. First take 0.168g of hexamethylenetetramine (HMT) and 0.362g of copper nitrate dihydrate Cu(NO 3 ) 2 Put it into a clean beaker, add 15mL of deionized water and stir in a magnetic stirrer for 15min, after the stirring is completed, add 0.77g of potassium bromide (KBr) and continue stirring for 10min to fully react the medicine and obtain a mixed solution; pour the mixed solution Put it into a polytetrafluoroethylene lining, put it into a stainless steel high-pressure reaction kettle and seal it. The reaction temperature is 95°C and the reaction is sealed for 2 hours; Pour the precipitate into a clean porcelain cup, dry it at a temperature of 65°C, grind and collect it, and obtain a light green powdery copper hydroxy bromide sample.

[0032] This embodiment is the best embodiment.

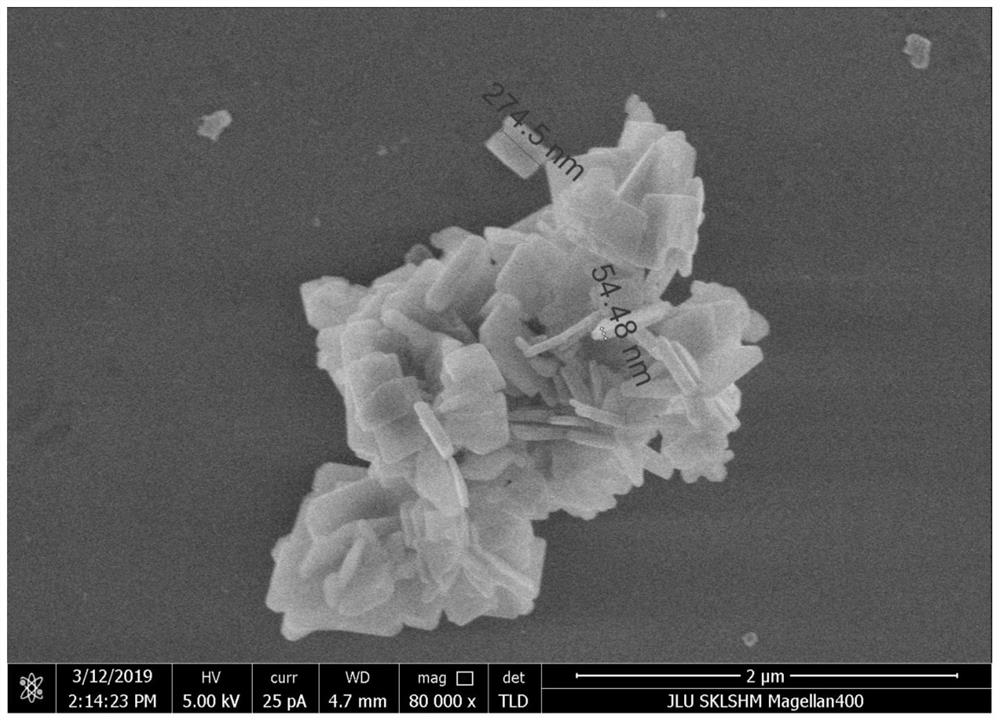

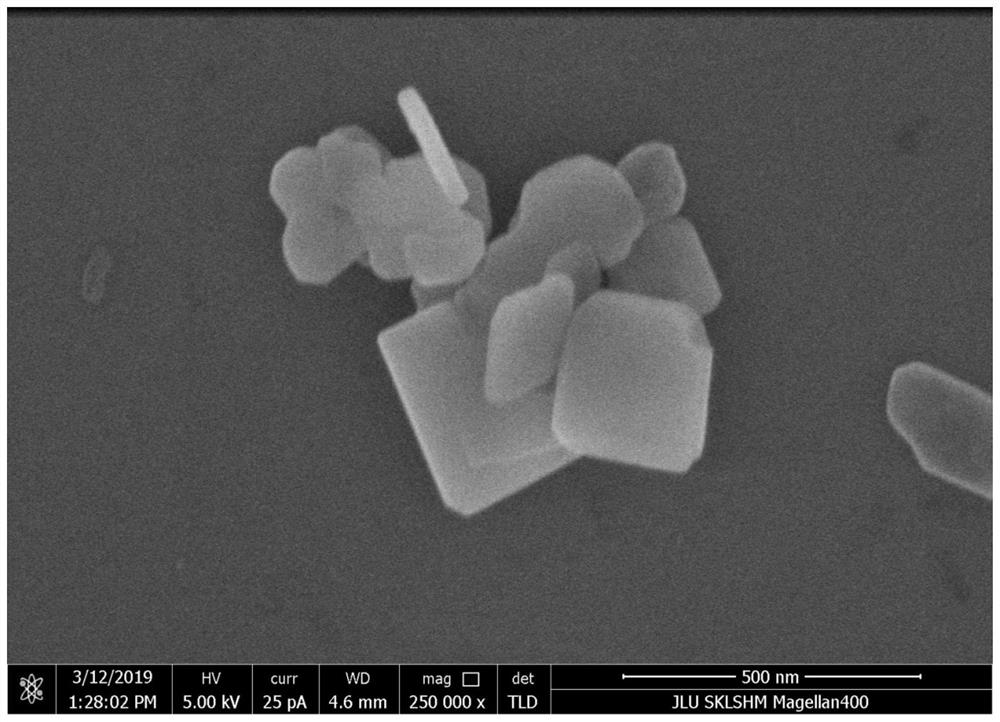

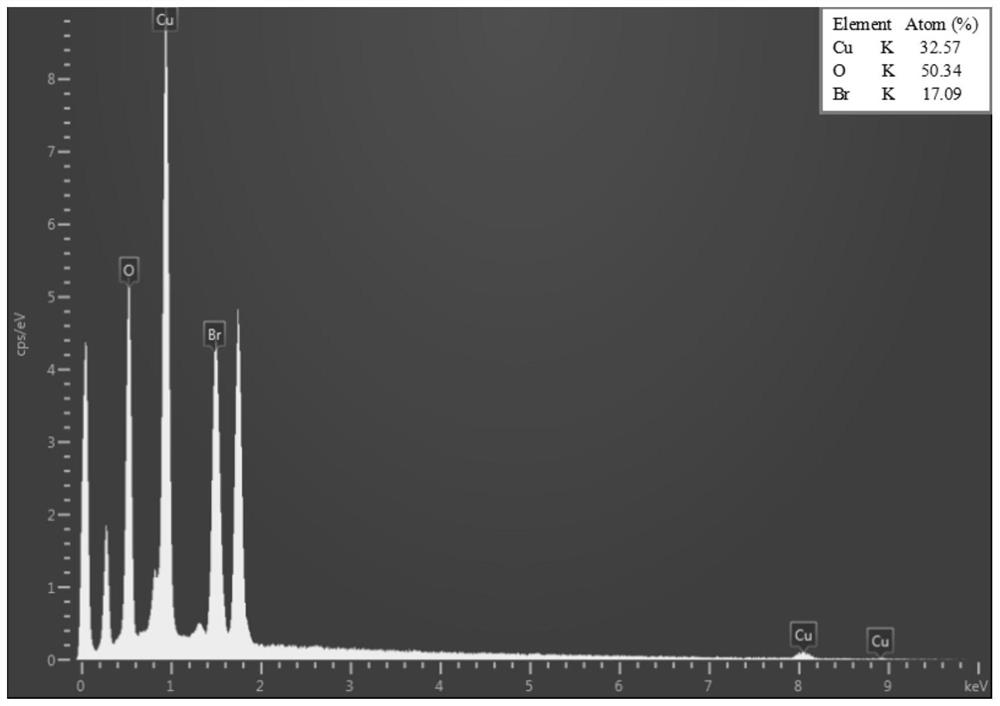

[0033] figure 1 Cu prepared under the ab...

Embodiment 2

[0035] High-purity copper nitrate dihydrate solid particles, hexamethylenetetramine particles, and potassium bromide particles are used as raw materials. First take 0.147g of hexamethylenetetramine (HMT) and 0.362g of copper nitrate dihydrate Cu(NO 3 ) 2 Put it into a clean beaker, add 15mL of deionized water and stir in a magnetic stirrer for 15min, after the stirring is completed, add 0.77g of potassium bromide (KBr) and continue stirring for 10min to fully react the medicine and obtain a mixed solution; pour the mixed solution Put it into a polytetrafluoroethylene lining, put it into a stainless steel high-pressure reaction kettle and seal it. The reaction temperature is 95°C and the reaction is sealed for 2 hours; Pour the precipitate into a clean porcelain cup, dry it at a temperature of 65°C, grind and collect it, and obtain a light green powdery copper hydroxybromide sample.

[0036] Figure 5 gives the prepared Cu 2 (OH) 3 Scanning electron microscope of Br crysta...

Embodiment 3

[0038] High-purity copper nitrate dihydrate solid particles, hexamethylenetetramine particles, and potassium bromide particles are used as raw materials. First take 0.189g of hexamethylenetetramine (HMT) and 0.362g of copper nitrate dihydrate Cu(NO 3 ) 2 Put it into a clean beaker, add 15mL of deionized water and stir in a magnetic stirrer for 15min, after the stirring is completed, add 0.77g of potassium bromide (KBr) and continue stirring for 10min to fully react the medicine and obtain a mixed solution; pour the mixed solution Put it into a polytetrafluoroethylene lining, put it into a stainless steel high-pressure reaction kettle and seal it. The reaction temperature is 95°C and the reaction is sealed for 2 hours; Pour the precipitate into a clean porcelain cup, dry it at a temperature of 65°C, grind and collect it, and obtain a light green powdery copper hydroxybromide sample.

[0039] Figure 6 gives the prepared Cu 2 (OH) 3 Scanning electron microscope of Br crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com