High-selectivity simple preparation method of apatinib

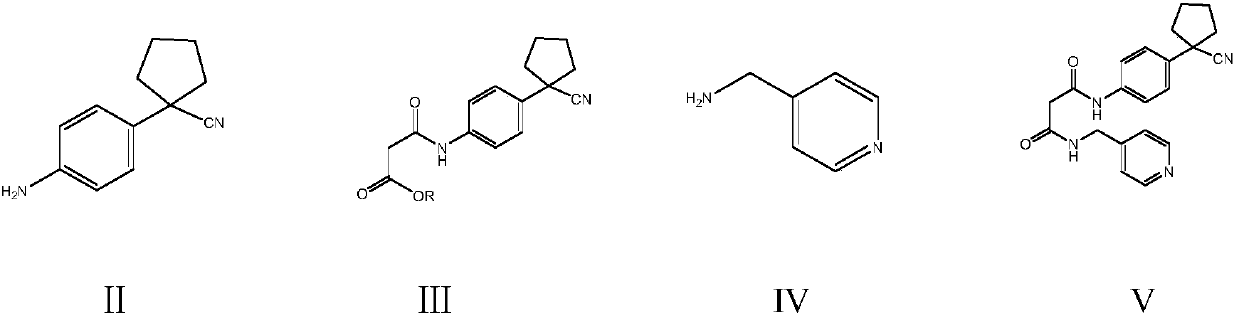

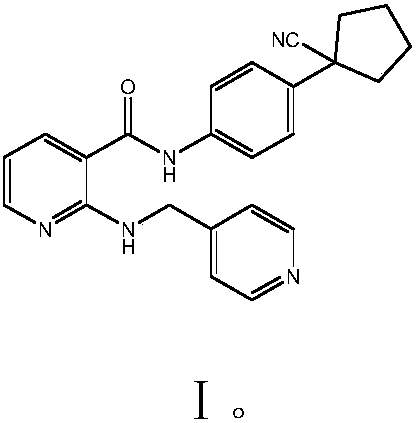

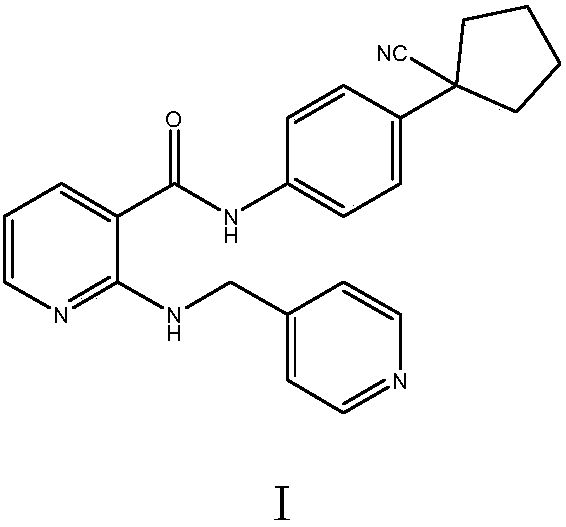

A technology of apatinib and the first amide, applied in the field of medicinal chemistry, can solve the problems of high price of 2-chloronicotinyl chloride, complicated steps, large amount of nitrification reaction wastewater, etc., and achieves high addition reaction activity and technological process. Simple, highly active methylene effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Preparation of N-(4-pyridine)methyl-N'-4-(1-cyanocyclopentyl)phenylmalonamide (V)

[0047] Into a 250 ml four-necked flask connected with a stirrer, a thermometer and a reflux condenser, add 120 g of dimethyl malonate and 18.6 g (0.1 mol) of 1-(4-aminophenyl)cyclopentylcarbonitrile II , Stir the dealcoholization reaction at 100~105℃ for 4 hours (first amidation reaction), recover the excess dimethyl malonate by distillation under reduced pressure, cool to 60-70℃, add 13.0g (0.12mol) 4-ammonia The methyl pyridine IV was stirred and dealcoholized at 110-115°C for 4 hours (the second amidation reaction). Cool to 30-40°C, add 80 g of isopropanol to the residue, recrystallize, filter, and dry to obtain 33.5 g of N-(4-pyridine)methyl-N'-4-(1-cyanocyclopentan Yl)phenylmalonamide, the yield is 92.6%, and the liquid phase purity is 99.8%.

Embodiment 2

[0048] Example 2: Preparation of N-(4-pyridine)methyl-N'-4-(1-cyanocyclopentyl)phenylmalonamide (V)

[0049] Into a 250 ml four-necked flask connected with a stirrer, a thermometer and a reflux condenser, add 150 g of diethyl malonate and 18.6 g (0.1 mol) of 1-(4-aminophenyl)cyclopentylcarbonitrile II , Stirring dealcoholization reaction at 105~110℃ for 4 hours (first amidation reaction), recovering excess diethyl malonate by distillation under reduced pressure, cooling to 60-70℃, adding 13.0g (0.12mol) of 4-ammonia The methyl pyridine IV was stirred and dealcoholized at 110-115°C for 4 hours (the second amidation reaction). Cool to 30-40°C, add 80 g of isopropanol to the residue, recrystallize, filter, and dry to obtain 33.1 g of N-(4-pyridine)methyl-N'-4-(1-cyanocyclopentan Base) phenylmalonamide, the yield is 91.3%, and the liquid phase purity is 99.9%.

Embodiment 3

[0050] Example 3: Preparation of N-(4-pyridine)methyl-N'-4-(1-cyanocyclopentyl)phenylmalonamide (V)

[0051] Into a 250 ml four-necked flask connected with a stirrer, a thermometer and a reflux condenser, 150 g of di-tert-butyl malonate and 18.6 g (0.1 mol) of 1-(4-aminophenyl)cyclopentylcarbonitrile were added Ⅱ. Stir the dealcoholization reaction at 110~115℃ for 4 hours (the first amidation reaction), recover the excess di-tert-butyl malonate by distillation under reduced pressure, cool to 60-70℃, add 13.0 g (0.12 mole) 4 -Aminomethylpyridine IV, at 120-125°C for 4 hours with stirring and dealcoholization (second amidation reaction). Cool to 30-40°C, add 80 g of isopropanol to the residue, recrystallize, filter, and dry to obtain 32.6 g of N-(4-pyridine)methyl-N'-4-(1-cyanocyclopentan Yl)phenylmalonamide, the yield is 90.1%, and the liquid phase purity is 99.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| chromatographic purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com