Method for preparing lithium metal through lithium contained minerals

A technology for lithium metal and minerals, applied in the field of lithium metal preparation from lithium-containing minerals, can solve problems such as long process, serious air pollution, and difficult temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

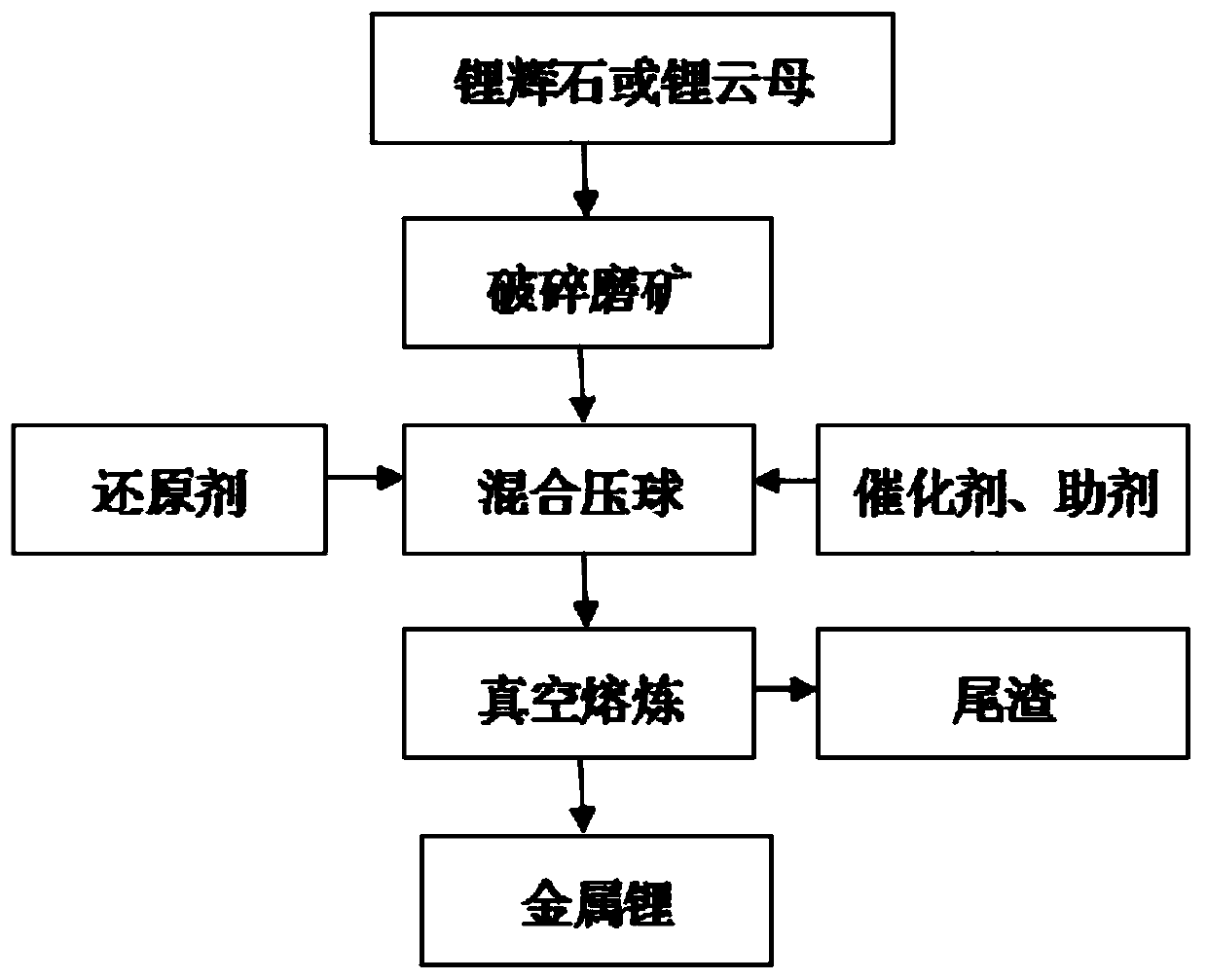

[0055] figure 1 Example 1 of the present invention is a flow chart for preparing lithium metal by taking spodumene as an example. After the spodumene is pulverized and ground, an auxiliary agent, a reducing agent and a catalyst are added to mix and press balls to obtain a mixed raw material, and then vacuum reduction is performed to obtain lithium metal. and tailings.

[0056] (1) According to dry spodumene raw material, light magnesia and aluminum-magnesium alloy in a weight ratio of 45:40:5, and add BaF 2 The mixed raw material is formed, and the mixed raw material is pressed into pellets under 50Mpa, and the particle size of the pellets made by pressing the mixed raw material is about 40mm. The added amount of magnesium fluoride is 2wt% of the amount of mixed raw materials. Light magnesium oxide MgO≥95wt%, SiO 2 ≤1.0wt%, P≤0.03wt%, S≤0.03wt%. The aluminum-magnesium alloy used is in powder form, the fineness is -120 mesh, and the chemical composition is Al: 10wt%, Mg: 90...

Embodiment 2

[0060] (1) According to the dry spodumene raw material, light magnesium oxide and aluminum-magnesium alloy, the weight ratio is 50:45:10, and MgF is added 2 and CaF 2 The mixture of the mixture forms a mixed raw material, which is pressed into pellets under 50Mpa; the particle size of the pellets made by pressing the mixed raw material is about 40mm. The added amount of fluoride is 5wt% of the amount of mixed raw materials. The aluminum-magnesium alloy used is in powder form, the fineness is -120 mesh, and the chemical composition is Al: 30wt%, Mg: 70wt%.

[0061] (2) Put the pellet material into the heating furnace, raise the temperature to 700°C at a heating rate of 15°C / min, keep the temperature constant for 60min, and maintain a vacuum of 1Pa; continue to raise the temperature, and raise the temperature to 1300°C at a heating rate of 15°C / min , and control the vacuum degree of the vacuum reactor to 1200Pa, until no more lithium vapor is generated, and keep the constant t...

Embodiment 3

[0064] (1) According to dry lepidolite raw material, light magnesia and aluminum-magnesium alloy, the weight ratio is 45:45:5 to form a mixed raw material, and the mixed material is pressed into pellets at 50Mpa; the pellet particle size of the mixed raw material is pressed About 40mm. The aluminum-magnesium alloy used is in powder form, the fineness is -120 mesh, and the chemical composition is Al: 30wt%, Mg: 70wt%.

[0065] (2) Add the pellets into the heating furnace, raise the temperature to 650°C at a heating rate of 13°C / min, keep the temperature constant for 40min, and maintain a vacuum of 1Pa; continue to heat up, and raise the temperature to 1250°C at a heating rate of 13°C / min , and control the vacuum degree of the vacuum reactor to 1150Pa, until no more lithium vapor is generated, and keep the constant temperature for about 3 hours; the heating furnace is an induction heating furnace for discontinuous production, and its fuel is gas.

[0066] (3) The reduced lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com