Oil displacement method of oil reservoir

An oil displacement method and oil displacement technology, which are applied in chemical instruments and methods, earthwork drilling, production of fluids, etc., can solve the problems such as the recovery factor to be improved, and reduce the viscosity of crude oil, improve the fluidity, and improve the efficiency of oil washing. The effect of sweeping efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This example is used to illustrate the preparation and performance of each slug provided by the present invention.

[0067] (1) Pre-slug A: Weigh 800g of clean water (with a salinity of 0mg / L), add polyacrylamide (viscosity average molecular weight 3000×10) under stirring conditions 4 , Degree of hydrolysis 20%) 3g, stirring and dissolving for 4h. Add 3 g of dimethyl dioctadecyl ammonium chloride as a cationic surfactant, add water to 1000 g, and stir for 20-30 minutes until completely dissolved.

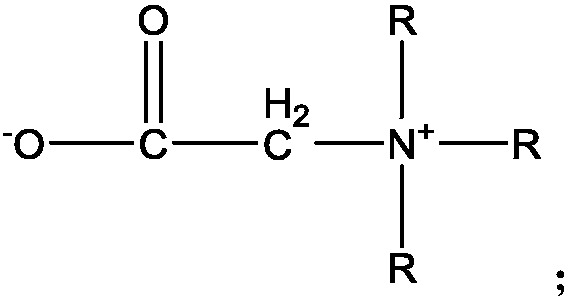

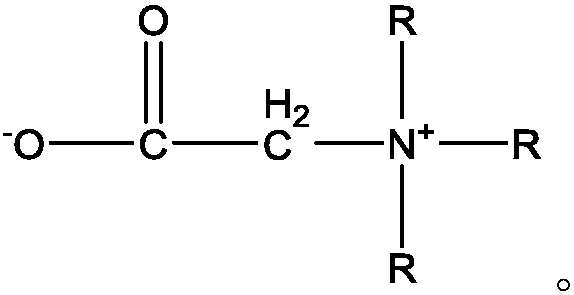

[0068] Viscosity-reducing flooding system B: Weigh 800g of clear water (with a salinity of 0mg / L), and add polyacrylamide (viscosity average molecular weight 3000×10) under stirring conditions 4 , Degree of hydrolysis 20%) 3g, stirring and dissolving for 4h. Add 3 g of dimethyl dioctadecyl ammonium chloride, a cationic surfactant, 3 g of octadecyl dimethyl betaine, and 0.5 g of ethanol, add water to 1000 g, and stir for 20-30 minutes until completely dissolved.

[0069] Protection ...

Embodiment 2

[0072] This example is used to illustrate the use effect of the oil displacement method on the enhanced oil recovery of heavy oil.

[0073] A core with a size of 4.5mm×4.5mm×300mm and a permeability of 3000md was used for the enhanced oil recovery experiment (the oil displacement system is the same as in Example 1). The core was dried, evacuated and saturated with water, saturated with heavy oil at 70°C (same as Example 1), and aged for 48h. (1) The injection rate of 1.5 mL / min is water driven to 95% by volume of water. (2) Inject the pre-slug A 0.05PV at 1.5mL / min injection rate, and inject CO at 1.0mL / min injection rate 2 0.05PV; (3) Inject the viscosity-reducing oil displacement system B0.05PV at 1.5mL / min injection rate, and inject CO at 1.0mL / min injection rate 2 0.05PV, repeated alternate injection for 3 cycles. (4) Inject the protective slug C 0.05PV at an injection rate of 1.5 mL / min; (5) Continue the water drive at an injection rate of 1.5 mL / min to 95 vol% water.

[0...

Embodiment 3

[0076] This example is used to illustrate the preparation and performance of each slug provided by the present invention.

[0077] (1) Use high salinity water (salinity 100000mg / L, of which Ca 2+ Concentration: 10000mg / L), pre-slug A, viscosity-reducing oil displacement system B and protective slug C are prepared. The preparation method is the same as in Example 1.

[0078] (2) Take the above-mentioned pre-slug A, viscosity reduction oil displacement system B and heavy oil (50℃ viscosity 9600mPa.s), and use Model TX500C interfacial tension to determine the interfacial tension at 70℃ to be 3.9×10 -4 mN / m and 6.3×10 -3 mN / m. In a 100 mL beaker, respectively take 30 g of the above-mentioned pre-slug A and viscosity-reducing oil displacement system B, add 70 g of heavy oil, and place the beaker in a water bath at 70°C for 2 hours and stir for 3 minutes. Using Brookfield DV-II viscometer at 70℃, the shear rate is 7.34S -1 Under the conditions, the measured viscosity of the mixed soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com