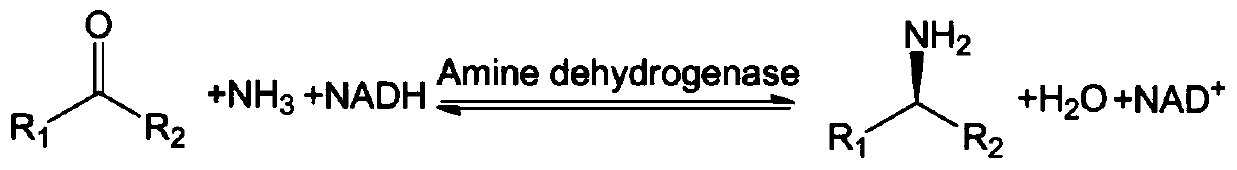

Amine dehydrogenase electrode and preparation method and application thereof

An amine dehydrogenase and electrode technology, applied in the field of biosensors, to achieve superior electronic performance, good stability and repeatability, and good chemical modification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

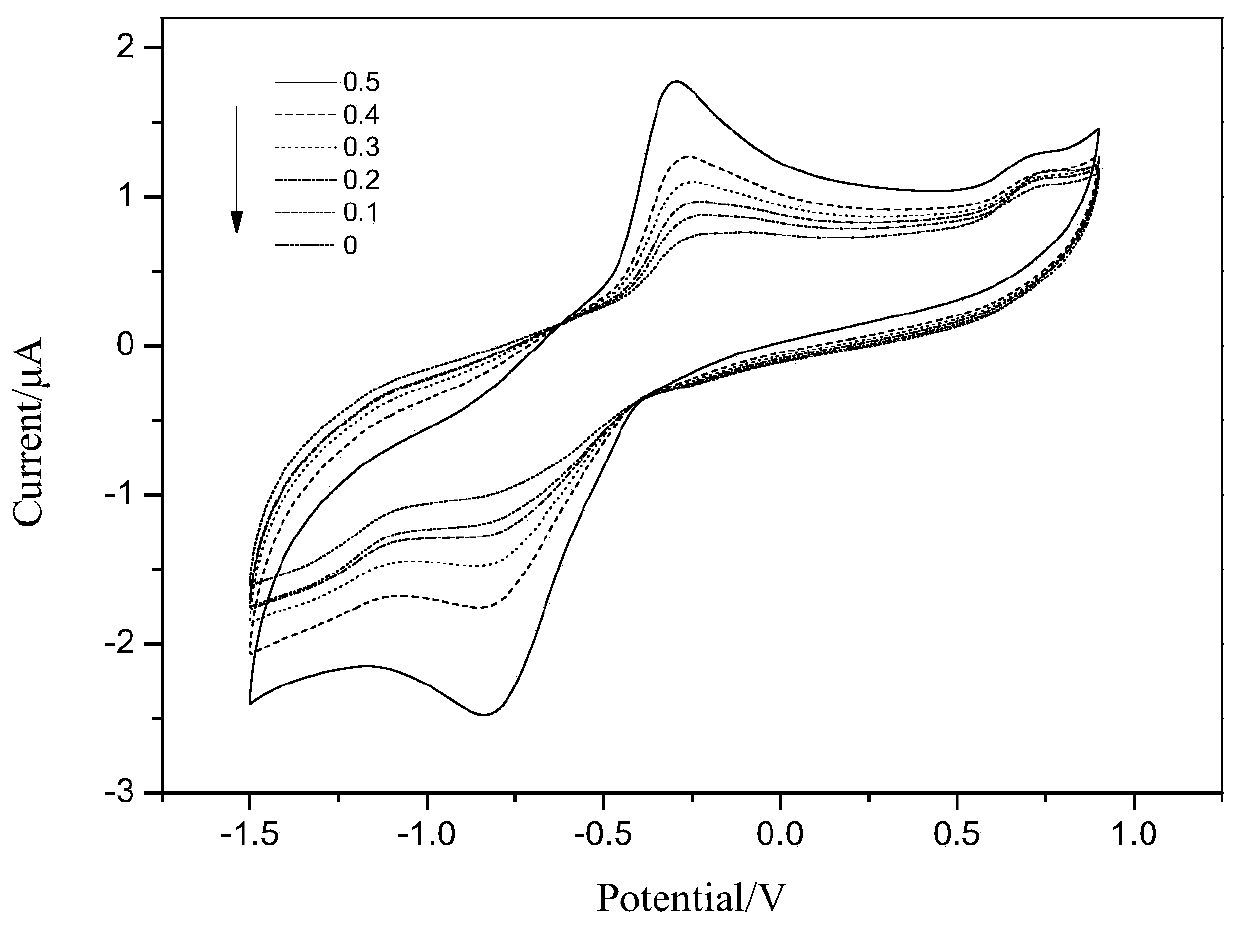

Examples

Embodiment 1

[0031](1) Preparation of crude enzyme of amine dehydrogenase: according to the original sequence of amine dehydrogenase shown in SEQ ID NO.1, primers shown in SEQ ID NO.2 and SEQ ID NO.3 were designed, provided by a commercial company ( Shanghai Bioengineering Co., Ltd.) used the PCR method to synthesize the gene sequence of amine dehydrogenase, which was used to connect with the vector pET28a to construct a plasmid.

[0032] Ligation of the PCR product (the gene sequence of amine dehydrogenase) and the vector pET28a: the PCR product and the vector pET28a were double digested with NdeI and XhoI, after purification, they were reacted overnight at 4°C under the action of T4DNA ligase to obtain the transformation plasmid. Competent cells were prepared using the Competent Cell Preparation Kit. Add 10ng of transformation plasmid to the competent cells, mix gently, place on ice for 30 minutes, place in a water bath at 42°C for 45 seconds, and immediately place on ice for 1 to 2 minu...

Embodiment 2

[0043] (1)-(3) The experimental procedures are as the steps (1)-(3) of Example 1.

[0044] (4) Preparation of enzyme electrode modification material rGO-PEI: graphene oxide was prepared by the Hummer method, and a uniformly dispersed GO solution was obtained after ultrasonic dispersion for 3 h. Under stirring, 100 mL of water, 200 mg of KOH and 300 mg of 187KDa branched PEI were sequentially added, stirred evenly, and 4.6 mL of 4.9 mg / mL GO solution was slowly added. After heating (80°C) to reflux for 24 hours, add 8 mL of 2mol / L sodium borohydride for reduction, and continue the reaction for 2 hours. After the reaction was completed, rGO-PEI was obtained by centrifugation and drying, and a 0.1 mg / mL rGO-PEI solution was prepared.

[0045] (5) Preparation of rGO-PEI-AmDH: Add the amine dehydrogenase solution obtained in step (2) with an enzyme concentration of 10 mg / ml to the amine dehydrogenase solution obtained in step 4) at a volume ratio of 1:1 at 4°C 0.1 mg / mL rGO-PEI s...

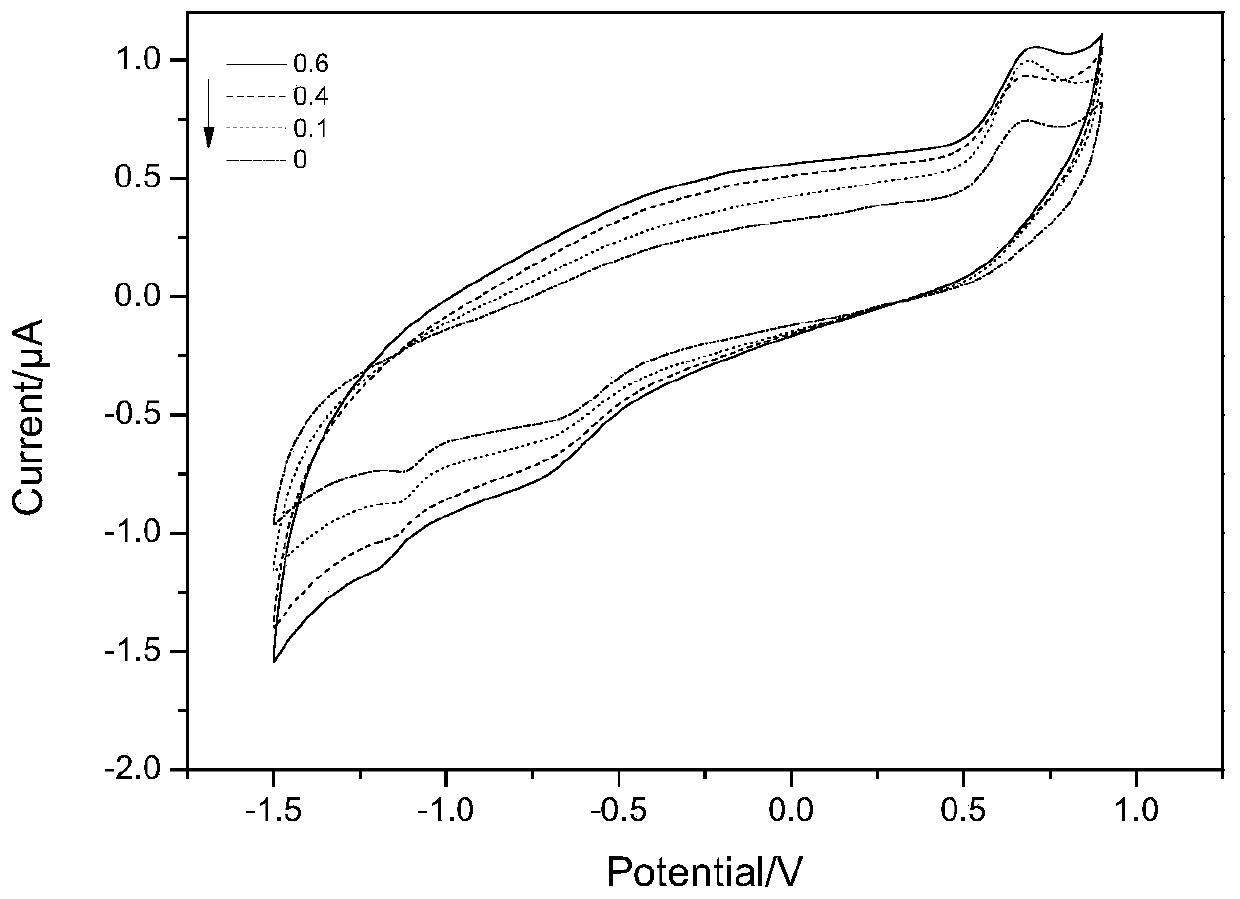

Embodiment 3

[0050] (1)-(3) The experimental procedures are as the steps (1)-(3) of Example 1.

[0051] (4) Preparation of enzyme electrode modification material rGO-PEI: graphene oxide was prepared by the Hummer method, and a uniformly dispersed GO solution was obtained after ultrasonic dispersion for 3 hours. Under stirring, 7 mL of water, 100 mg of KOH and 200 mg of PEI were sequentially added, stirred evenly, and 4.6 mL of 4.9 mg / mL GO solution was slowly added. After heating (80°C) to reflux for 24 hours, add 8 mL of 2mol / L sodium borohydride for reduction, and continue the reaction for 2 hours. After the reaction was completed, rGO-PEI was obtained by centrifugation and drying, and a 1 mg / ml rGO-PEI solution was prepared. The polyethyleneimine includes linear PEI with a molecular weight range of 217KDa, and its concentration is 50mg / ml;

[0052] (5) Preparation of rGO-PEI-AmDH: Add the amine dehydrogenase solution with an enzyme concentration of 5 mg / mL obtained in step (2) to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com