Animal feed coated trace element premix

A technology of trace elements and animal feed, which is applied in the direction of animal feed, forming or processing of animal feed, adding food elements, etc., can solve problems such as unfavorable operation, reduced effective effect, agglomeration and discoloration, etc., to reduce the amount of addition, reduce Catalytic oxidation, delayed digestion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The weight percent of the raw material components of the granulated binder is: 55% of hydroxyethyl methylcellulose, 25% of coumarin, and 20% of phosphate starch.

[0028] Mix 100 parts of the measured copper, iron, zinc, manganese, iodine, selenium, cobalt trace element compound premix, 8 parts of granulated binder, and 10 parts of water, mix at high speed, granulate on a granulator or a granulator, and wrap on a coating machine film, add 3.5 parts of coating material to make the coating trace element premix. The percentage by weight of the raw material components of the coating material is: 60% of quaternary ammonium cationic starch and 40% of propylene glycol monostearate.

Embodiment 2

[0030] The weight percent of the raw material components of the granulated binder is: 60% of hydroxyethyl methylcellulose, 15% of coumarin, and 25% of phosphate starch.

[0031] Mix 100 parts of the measured copper, iron, zinc, manganese, iodine, selenium, cobalt trace element compound premix, 13 parts of granulated binder, and 15 parts of water, mix at high speed, granulate on a granulator or a granulator, and wrap on a coating machine film, add 5 parts of coating material to make the coating trace element premix. The percentage by weight of the raw material components of the coating material is: quaternary ammonium type cationic starch 70%, propylene glycol monostearate 30%.

Embodiment 3

[0033] The percentage by weight of the raw material components of the granulated binder is: 40% of hydroxyethyl methylcellulose, 35% of coumarin, and 25% of phosphate starch.

[0034] Mix 100 parts of the measured copper, iron, zinc, manganese, iodine, selenium, cobalt trace element compound premix, 3 parts of granulated binder, and 5 parts of water, mix at high speed, granulate on a granulator or a granulator, and wrap on a coating machine film, add 1 part of coating material to make the coating trace element premix. The percentage by weight of the raw material components of the coating material is: quaternary ammonium cationic starch 45%, propylene glycol monostearate 55%.

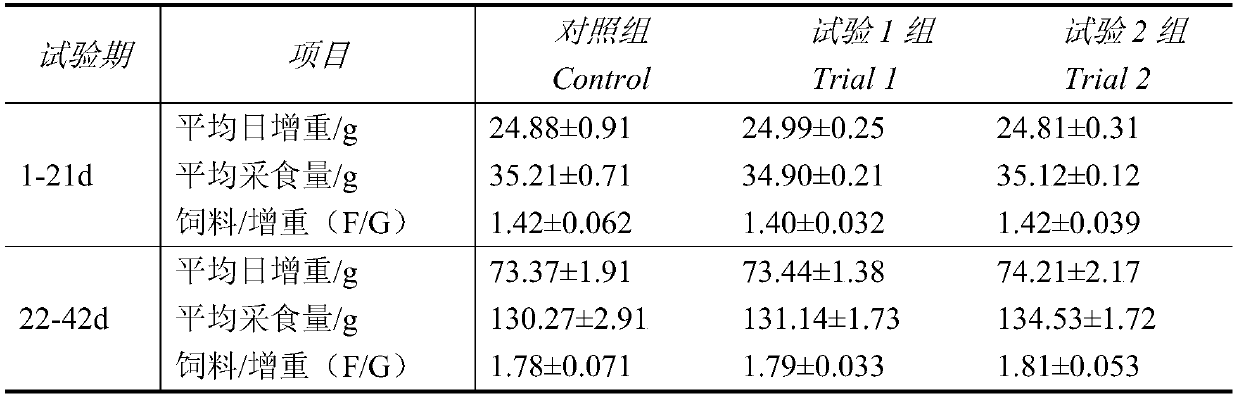

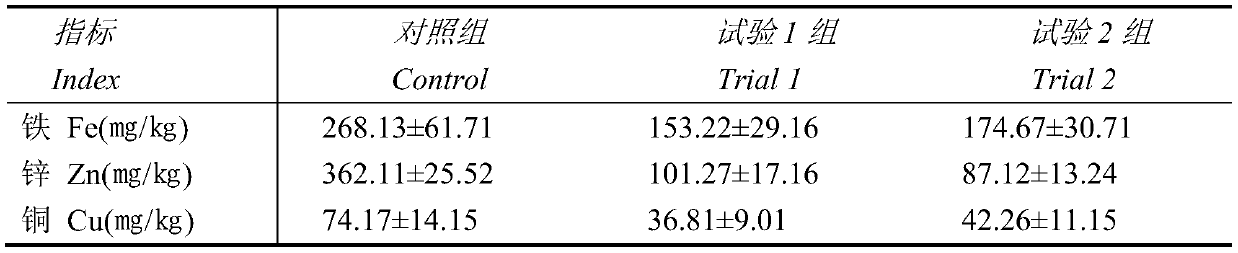

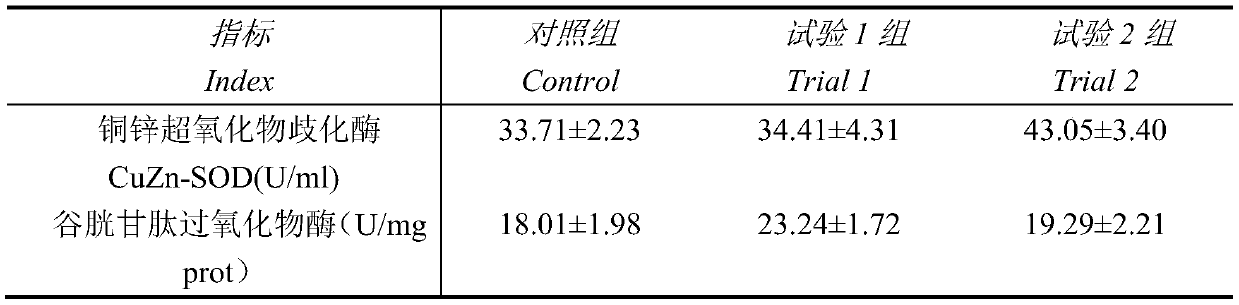

[0035] In order to prove the feeding effect of the present invention, a broiler feeding test has been carried out. The 1-day-old broiler chickens were selected and fed with the same compound feed. They were divided into control group and test group. 300g / T ration and 500g / T ration of the coated microel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com