Crosslinked bioprosthesis valve processing method

A technology of biological valves and treatment methods, applied in the field of biomedical materials and medical devices, can solve the problems of inability to eliminate inflammatory reactions, toxicity, calcification, etc., achieve good blood compatibility, good mechanical properties, and reduce inflammatory reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

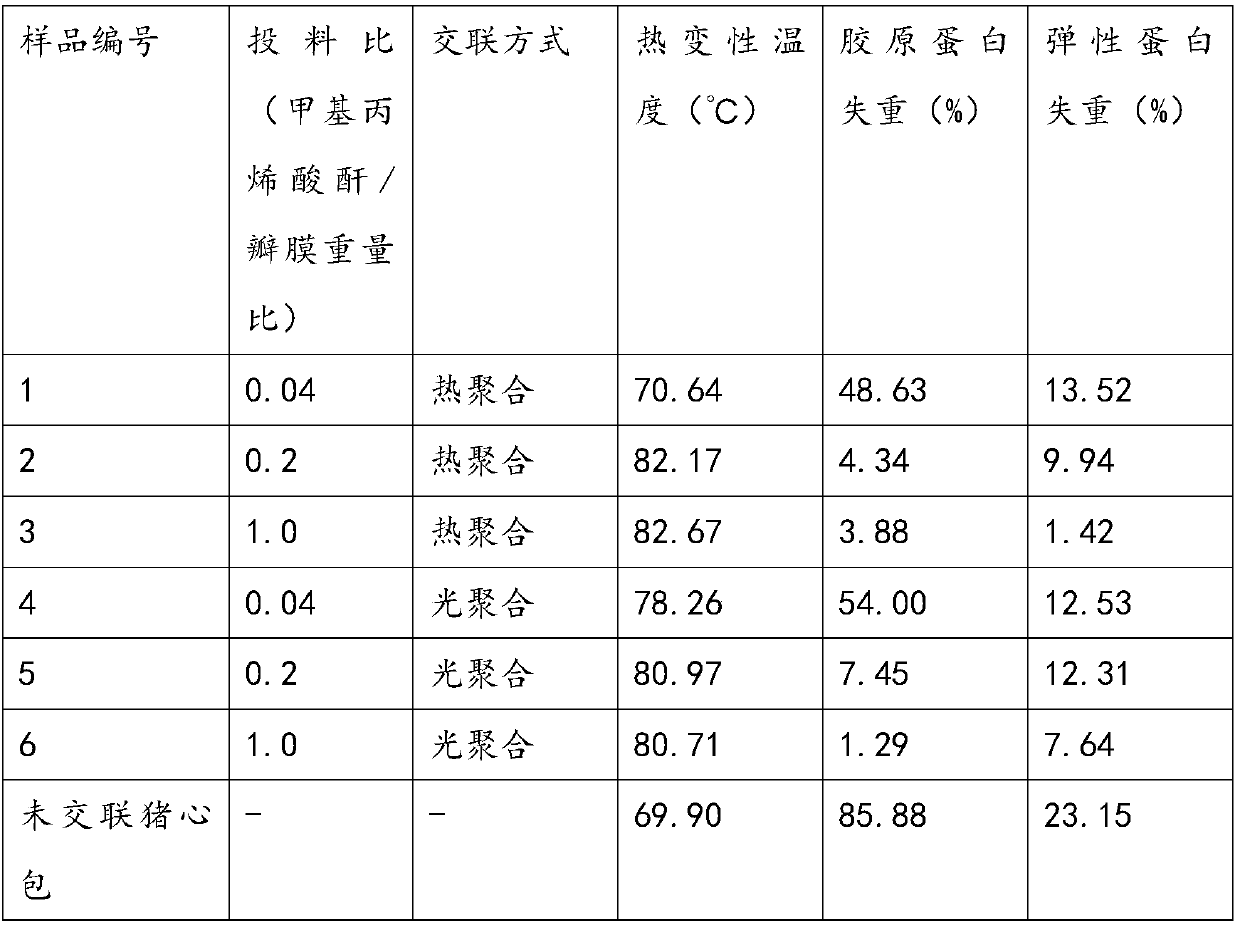

Embodiment 1

[0027] A method for processing a cross-linked artificial biological valve. The biological valve is obtained through a three-step process. The first step is to modify the heterogeneous biological tissue and an unsaturated group compound to react with an unsaturated group, and the second step is to obtain a cross-linked biological valve through free radical polymerization. Linked biological valve tissue, the third step is to process the residual unsaturated groups in the cross-linked tissue to eliminate unreacted unsaturated groups. The xenogeneic biological tissue includes decellularized or non-decellularized porcine arterial valve, porcine pericardium or bovine pericardium. The unsaturated groups are (meth)acrylamide, (meth)acrylate, allyl. The free radical polymerization method is thermal polymerization or photopolymerization, wherein the thermal polymerization initiator is an organic peroxide initiator, an inorganic peroxide initiator, an azo initiator, a redox initiator, pr...

Embodiment 2

[0041] In this example, the porcine pericardium prepared in Example 1 was soaked in 5 mM ammonium persulfate / sodium bisulfite solution for thermal polymerization, placed at 37 degrees for 24 hours, and the cross-linked valve was treated with ethanol and Rinse thoroughly with deionized water.

Embodiment 3

[0043] In this implementation, the porcine pericardium prepared in Example 1 was soaked in 0.5% initiator Igcure2959 solution overnight at 37 degrees centigrade for the photopolymerized porcine pericardium, and the valve was taken out and irradiated with ultraviolet light for 10 minutes to complete cross-linking. The crosslinked valves were rinsed thoroughly with ethanol and deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com