A kind of light-cured coated controlled-release fertilizer and preparation method thereof

A controlled-release fertilizer and coating technology, which is applied in layered/coated fertilizers, fertilizer mixtures, fertilization devices, etc., can solve the problems of high production technology content, non-degradability, and complex processes, and achieves improved nutrient utilization and improved nutrient utilization. The effect of nutrient release period and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

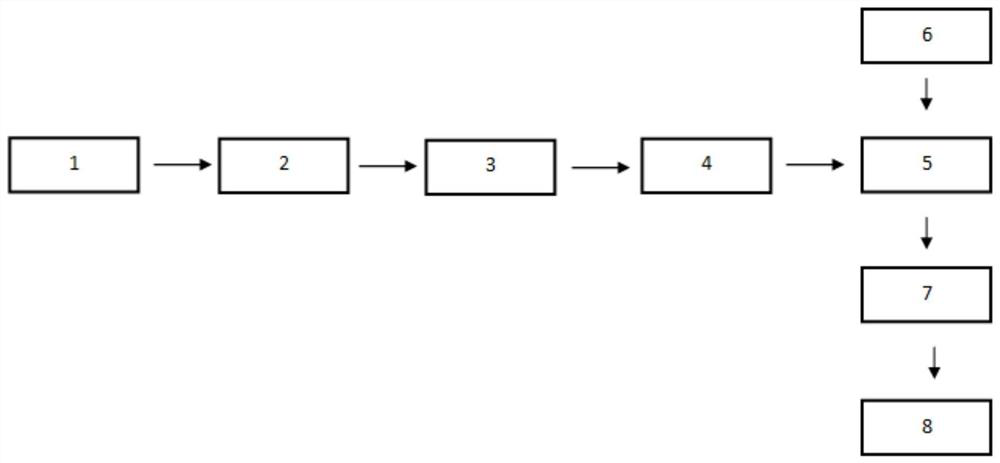

[0033] Based on this, the present invention provides a heat-free, ultraviolet-cured coated controlled-release fertilizer. In one embodiment of the present invention, the preparation method of the coated controlled-release fertilizer of this heating-free ultraviolet light curing is provided, comprising the following steps:

[0034] (1) Mechanically pulverize the waste branches of fruit trees to make powder. With the participation of acid catalyst (fluorine sulfonic acid), mix them according to the weight ratio of fruit tree waste branches powder and liquefaction agent A at 1:1~10 and add them to the magnetic stirring high pressure reaction. In the kettle, the acidic catalyst is 5%-7% of the total weight of the fruit tree waste branch powder and the liquefaction agent, and the temperature is raised to 250-350° C., and the liquefaction product of the fruit tree waste branch can be obtained by stirring continuously for 90 minutes; the liquefaction agent A It is a mixture of one or...

Embodiment 1

[0052] The waste branches of fruit trees (waste branches of apple trees) are mechanically pulverized and made into powder. Take by weighing 1000g powder, join in the magnetic stirring autoclave, add 540g fluorosulfonic acid as catalyzer, add 8000g liquefaction agent (supercritical dihydroergocalciferol and supercritical ergocalciferol mix uniformly by weight 4:1 as Liquefaction agent), under the condition of stirring, open the liquefier and rapidly raise the temperature to 290°C, and continue to stir and react for 90 minutes to obtain the liquefaction product of fruit tree waste. Add the liquefied product to a decolorizing column with a diameter of 10 cm and a length of 50 cm equipped with decolorizing agent B (decolorizing agent B is mesoporous micron activated carbon, magnesium oxide and iron oxide are mixed uniformly in a weight ratio of 4:1:1) , after the liquefied product slowly flows out, the decolorized liquefied product is obtained. Mix the decolorized liquefied produ...

Embodiment 2

[0054] The fruit tree waste branches (peach tree waste branches) are mechanically crushed to make powder. Take by weighing 1500g powder, join in the magnetic stirring autoclave, add 475g fluorosulfonic acid as catalyst, add 8000g liquefaction agent (supercritical dihydrosinacinol, supercritical tetrahydrofuran-oxypropylene copolymerized glycol and supercritical ergocalciferol Mix evenly according to the weight ratio of 1:1:1 and use it as a liquefaction agent), under the condition of stirring, the reaction kettle is opened and the temperature is rapidly raised to 300°C, and the stirring reaction is continued for 90 minutes to obtain the liquefied product of fruit tree waste branches. Add the liquefied product to a decolorizing column with a diameter of 10 cm and a length of 50 cm equipped with decolorizing agent B (decolorizing agent B is a mixture of mesoporous nano-chitosan, magnesium oxide and iron oxide in a weight ratio of 4:1:1 Uniform), after the liquefied product flows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com